What is the principle of twin-screw extruder? It has these features when it works!

What is the principle of twin-screw extruder?

1. There are two kinds of co-rotating intermeshing twin-screw extruders, low speed and high speed. The difference lies in the design, operating characteristics and application fields of the two extruders. The former is mainly used for profile extrusion, while the latter is used for special polymers. processing.

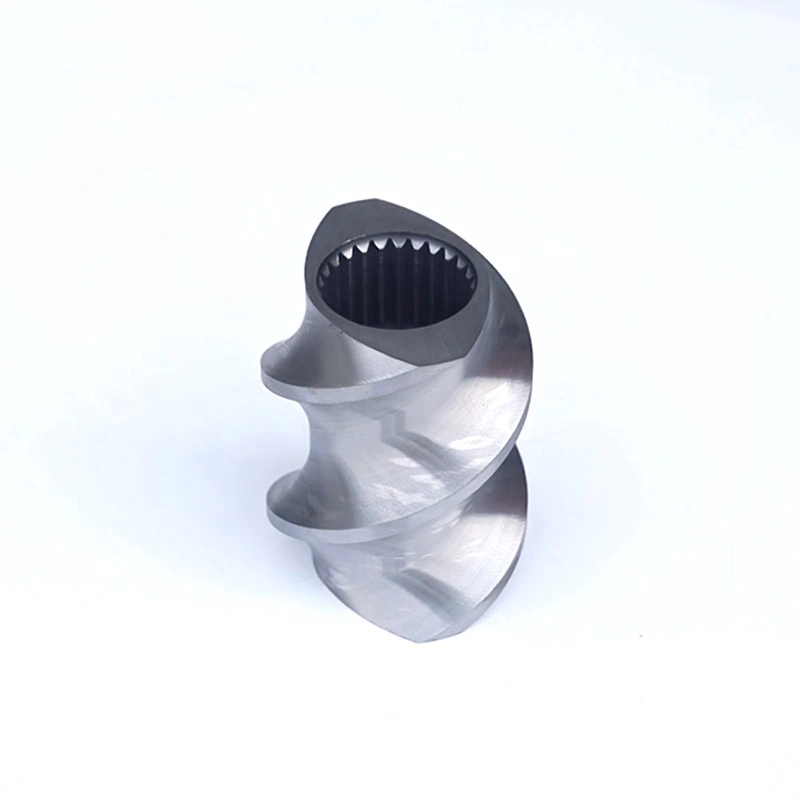

2. A close-meshing extruder is a low-speed extruder with a close-meshing screw geometry. The angular shape of one of the screws closely matches the shape of the grooves of the other screw, ie the conjugate screw shape.

3. Theoretically speaking, the co-rotating twin-screw extruder can be designed so that the screw grooves are fully meshed and sealed horizontally, but the longitudinal direction cannot be sealed and must be opened, otherwise the screws will not mesh.

The working characteristics of the twin-screw extruder:

1. As a twin-screw extruder, the internal relationship between the reaction process, speed, performance, screw structure and operating conditions during extrusion reaction molding is established to guide the reaction molding extrusion.

2. The twin-screw extruder can also be used for XLPE pipe granulation, such as hot water crosslinking masterbatch. Hybrid extrusion of thermosets such as phenolic resins, epoxies and powder coatings.

3. Twin-screw extruders are also used in hot-melt adhesive and polyurethane reaction extrusion granulation industry, such as EVA hot-melt adhesive and polyurethane. k Resin and SBS devolatilization granulation.

After reading the introduction of TENGDA Plastic Extruder Machine Manufacturers, do you know more about twin-screw extruders? If you still encounter any questions during the operation, you can contact us at any time!

Currently there is a global trend growing. People are more conscious about extruder machine manufacturers and are seeking alternatives to traditional solutions.

Nanjing Tengda Machinery Co., Ltd.’s mission is to be the leading global innovator, developer and provider of Application plastic extruder machine manufacturers products, systems, and services.

Nanjing Tengda Machinery Co., Ltd.’s model also predicts (i) a positive effect of management on firm performance; (ii) a positive relationship between product market competition and average management quality (part of which stems from the larger covariance between management with firm size as competition strengthens); and (iii) a rise (fall) in the level (dispersion) of management with firm age.

Application can be applied in different ways as extruder machine manufacturers.

Nanjing Tengda Machinery Co., Ltd. might focus its marketing efforts by highlighting its end product—improved technology and increased profits—not its producing methods.