What is the principle of twin-screw extruder? Its research direction is like this!

What is the principle of twin-screw extruder?

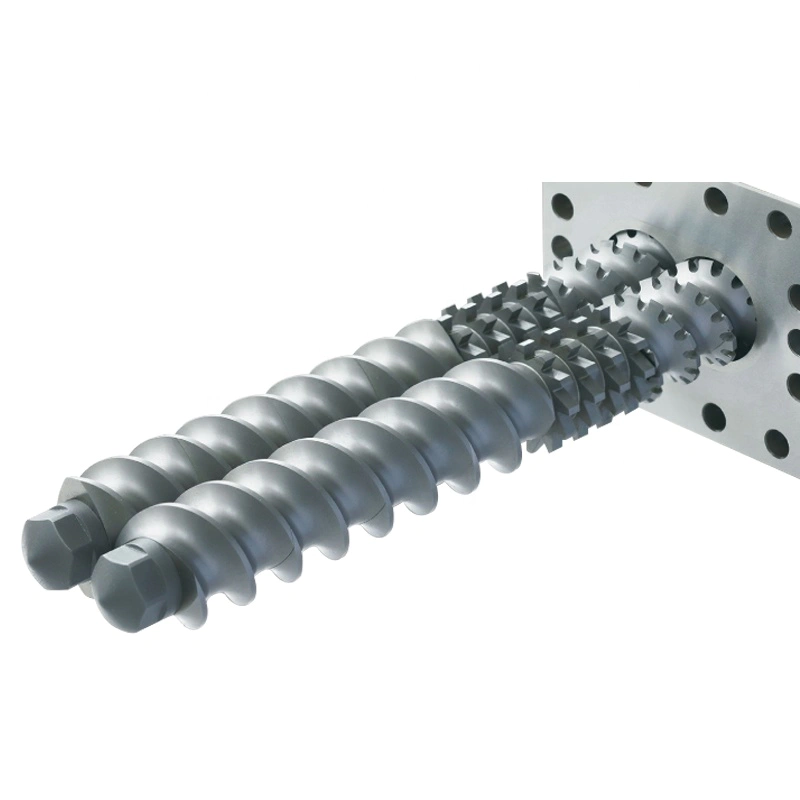

1. The twin-screw extruder has the basic extrusion principles of the single-screw extruder: solid conveying, melt pressurization and pumping, mixing stripping and evaporation, but not limited to this. The development of twin-screw extrusion theory is relatively late, coupled with its wide variety, messy screw shape, and messy extrusion process, it brings many difficulties to the research.

2. Generally speaking, the research on twin-screw extrusion theory is still in the development stage, known as“more technology than science”. From the point of view of its entire extrusion process, there are about three parts: the rules of polymer state change during the extrusion process, the basic principles of transportation, the transportation of solid melts, the exhaust phase and the law, and the establishment of a mathematical physical model , used to guide the design of the twin-screw extruder and the optimization of the extrusion system process.

The research direction of twin-screw extruder is as follows:

1. The physical model and mathematical model of the twin-screw extruder are established to guide the design of the twin-screw extruder and the optimization of the extrusion process.

2. It is necessary to understand the relationship between two or more polymers and materials in the whole process of extrusion, the real state change, the mixing form, the whole process of structural change, and the later mixing and characteristics.

3. As a twin-screw extruder, it has established the inner connection between the whole reaction process, speed and characteristics of extrusion reaction molding, and the screw structure and operating conditions. It can be extruded through reaction molding.

The above is about the principle of the twin-screw extruder? Its research direction is like this. If you want to know more details, you can follow our next article update!

Note: Some pictures are from the Internet, if there is any infringement, please contact to delete!

In the past few decades, plastic extruder machine manufacturers production has increased because of the use of Application.

Nanjing Tengda Machinery Co., Ltd. plans to produce and execute four marketing seminars, one per quarter, to help business owners see success by sharing important growth strategies and hosting interactive workshops.

Nanjing Tengda Machinery Co., Ltd.’s model also predicts (i) a positive effect of management on firm performance; (ii) a positive relationship between product market competition and average management quality (part of which stems from the larger covariance between management with firm size as competition strengthens); and (iii) a rise (fall) in the level (dispersion) of management with firm age.

With its quality certified and recognised by professional intitutions and customers, Nanjing Tengda Machinery Co., Ltd. is one of the leading providers in China.

The proprietor has many years experience in providing promotion services and is a sought after expert in Application.