What is the structure of plastic recycling granulator

What is the structure of the plastic recycling granulator'>What is the structure of the plastic recycling granulator

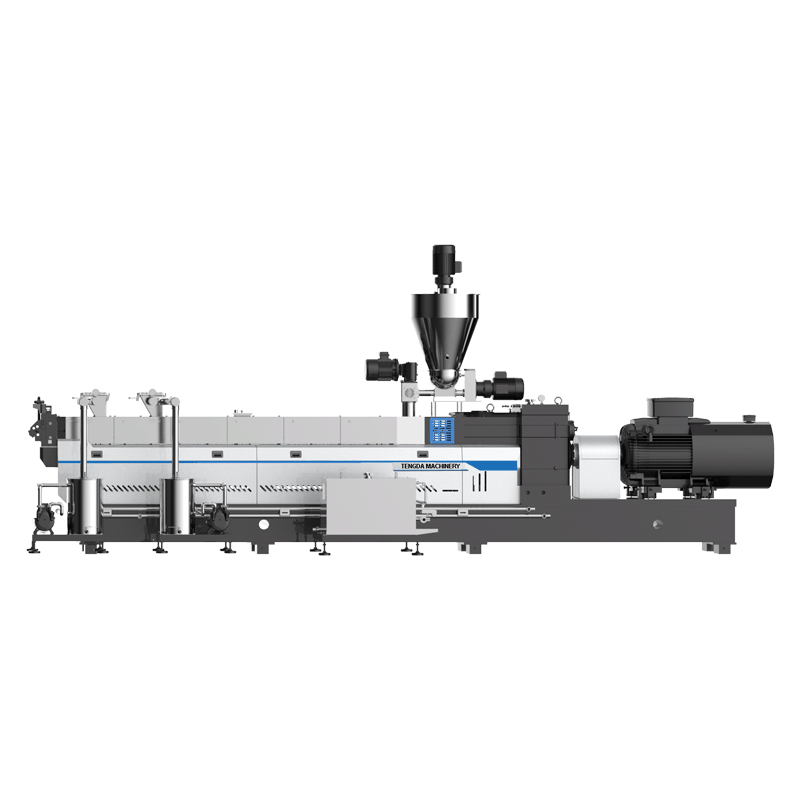

The main engine of the plastic granulator is an extruder, which consists of a kneading system, a transmission system and a heating and cooling system.

Kneading system The kneading system includes a screw, a barrel, a hopper, a head, and a mold. The plastic is plasticized into a uniform melt through the kneading system, and is continuously extruded by the screw under the pressure established in this process. nose.

(1) Screw: It is the main component of the plastic recycling granulator extruder, which is directly related to the application planning and productivity of the extruder. It is made of high-strength and corrosion-resistant alloy steel.

(2) Plastic recycling granulator barrel: It is a metal cylinder, generally made of alloy steel with heat resistance, high compressive strength, stable wear resistance and corrosion resistance or composite steel pipe lined with alloy steel. The barrel cooperates with the screw to complete the damage, softening, melting, plasticizing, exhausting and compacting of the plastic, and continuously and evenly transports the rubber to the molding system. Generally, the length of the barrel is 15 to 30 times its diameter, so that the plastic can be fully heated and fully plasticized as the criterion.

(3) Hopper: The bottom of the hopper is equipped with blocking equipment to adjust and block the material flow, and the side of the hopper is equipped with sight holes and calibration measuring equipment.

(4) Machine head and mold: The machine head is composed of an alloy steel inner sleeve and a carbon steel outer sleeve, and a forming mold is installed in the machine head. The function of the machine head is to convert the rotating plastic melt into parallel linear motion, evenly and smoothly introduce it into the mold sleeve, and give the plastic the necessary molding pressure. The plastic is plasticized and compacted in the barrel of the plastic recycling granulator, and flows into the forming die of the die through the porous filter plate along a certain flow channel through the neck of the die. , so that the plastic melt forms a continuous and dense tubular coating around the core wire. In order to ensure a reasonable plastic flow channel in the machine head and eliminate the dead angle of accumulated plastic, a shunt sleeve is often arranged. In order to eliminate the unstable pressure during plastic extrusion, a pressure equalizing ring is also provided. The machine head is also equipped with mold correction and adjustment equipment, which is convenient to adjust and correct the concentricity of the mold core and the mold sleeve.

The recovered waste plastics are first broken into granules with a damage machine, and then granulated after selection and cleaning. If the waste plastic is damaged, the model is generally 30HP or above, and it is also useful for small machines, depending on the recovered materials.

If you are looking for convenient, affordable , TENGDA brings plethora of options to suit your requirements and budget both. Check TENGDA Extruder Machine Manufacturers for more details.

All you women out there looking for amazing to dazzle the world try Nanjing Tengda Machinery Co., Ltd. latest collections at TENGDA Extruder Machine Manufacturers. Try it!

To properly understand what customers want, when, why and how they want it, Nanjing Tengda Machinery Co., Ltd. needs to pivot toward sentiment analysis, a burgeoning technology that taps into consumer demand based on natural language processing.

In a nutshell, is actually an ultimate solution for extruder machine manufacturers and underestimating its value cost you higher than anything else. So grab it before you miss the boat.

is something that has been around for a few decades now, enjoying it's heyday back in the plastic extruder machine manufacturers.