What is the waste gas treatment process produced by the plastic granulator

What is the waste gas treatment process produced by the plastic granulator

Overview of plastic granulation waste gas

Plastic is a polymer made of high molecular synthetic resin. With the rapid development of industry and the continuous improvement of plastic performance, plastic has been widely used in every field of our life. However, there will be a lot of organic waste gas in the process of plastic production. The waste gas mainly comes from the plastic heating wire drawing granulation process. The granulator dissolves the plastic process. There is a certain amount of white glue smoke, and the concentration is high; It will cause air pollution, damage the surrounding environment and affect the health of surrounding people. Therefore, in order to protect the environment and to be qualified for environmental protection, it is necessary to conduct organized discharge after treatment;

Plastic granulation waste gas treatment method

First and foremost, plastic waste gas is a type of organic waste gas; now the common organic waste gas treatment methods are: activated carbon adsorption method, catalytic incineration method, direct incineration method, UV photolysis method; let's introduce these methods. The principle and advantages and disadvantages of;

(1) Activated carbon adsorption method;

The main principle of this method is to use the adsorption of activated carbon to organic waste gas molecules, so that organic waste gas molecules are adsorbed on the surface of activated carbon, and then achieve the purpose of purifying waste gas; the adsorption method is currently mainly used in large air volume, low concentration, no dust, no oil and Water, normal temperature waste gas;

The benefits are high purification efficiency, convenient operation, and low investment;

The defect is that after the adsorption is full, it is necessary to find a professional environmental protection company for hazardous waste treatment;

Therefore, in general, in the management of waste gas, activated carbon is not used alone, and a CO furnace or UV photo-oxygen machine is allocated;

(2) Regenerative incineration method

The use of regenerative incineration method requires other fuels or combustion-supporting gas to heat the temperature in the furnace or regenerative ceramics to above 760 degrees. Use high temperature to decompose organic waste gas molecules, convert them into harmless CO2 (carbon dioxide) and H2O (water), and then discharge them in an organized manner;

The benefit of this method is that the purification power is high; it can handle high-concentration exhaust gas;

The disadvantage is that combustion-supporting fuels, such as natural gas, are required; and the operating cost is high, which is suitable for 24-hour continuous production lines;

(3) Catalytic incineration

The catalytic incineration method generally allocates activated carbon boxes or zeolite molecular sieves; first, the activated carbon boxes or zeolite molecular sieves are used to adsorb and concentrate the organic waste gas; after the adsorption is full, the CO furnace is started, and hot air is used to desorb the activated carbon or zeolite; The high-concentration exhaust gas enters the CO furnace and undergoes flameless combustion (catalytic decomposition) under the action of precious metal catalyst and high temperature;

The function of the catalyst is to reduce the decomposition temperature of organic waste gas molecules, and at a temperature of 200-400 degrees, it can be decomposed into carbon dioxide and water;

The advantage of this method is that the investment and operating costs are relatively low, and it is suitable for continuous production lines;

The disadvantage is that the exhaust gas cannot contain components that can cause catalyst poisoning, such as mercury, sulfide, etc.;

(4) UV photolysis method

The UV photolysis method uses high-energy ultraviolet beams to decompose oxygen molecules in the air to generate daily oxygen, and reactive oxygen species react with oxygen in the air to form sampling; ozone has strong oxidizing properties, and cooperates with the joint action of ultraviolet beams to make organic waste gas and odorous gases. Substances are degraded and converted into low molecular weight compounds, CO2 and H2O.

Advantages: stable operation, low investment and operation cost, high purification efficiency;

The disadvantage is that if only one photo-oxygen machine is needed, it is difficult to pass the standard under normal circumstances, and activated carbon needs to be distributed;

For the study, researchers defined TENGDA as strategies to foster some social good, including programs that benefit community engagement, diversity, the environment, human rights and employee relations.

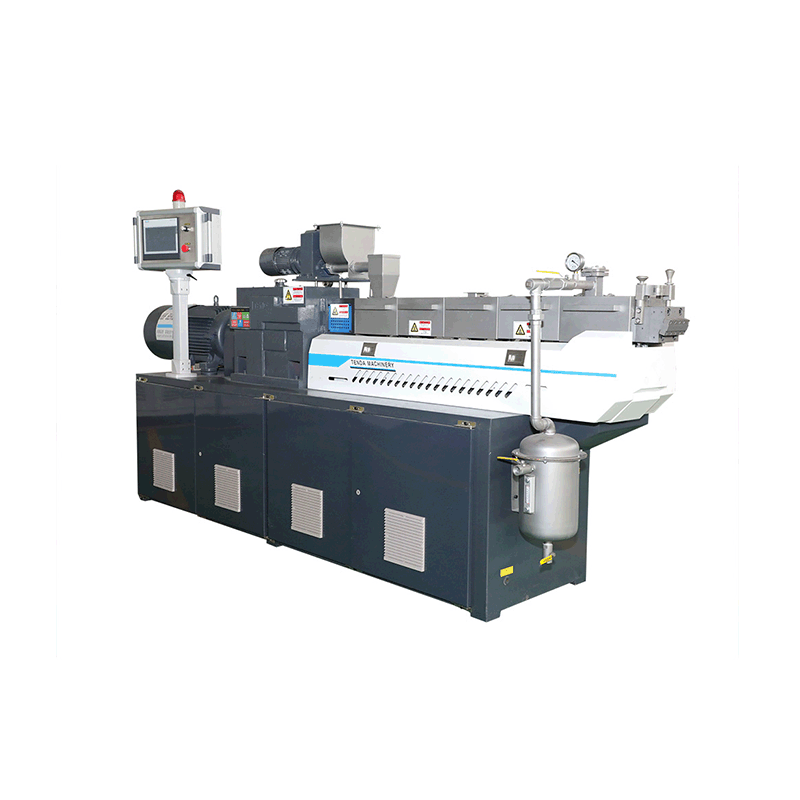

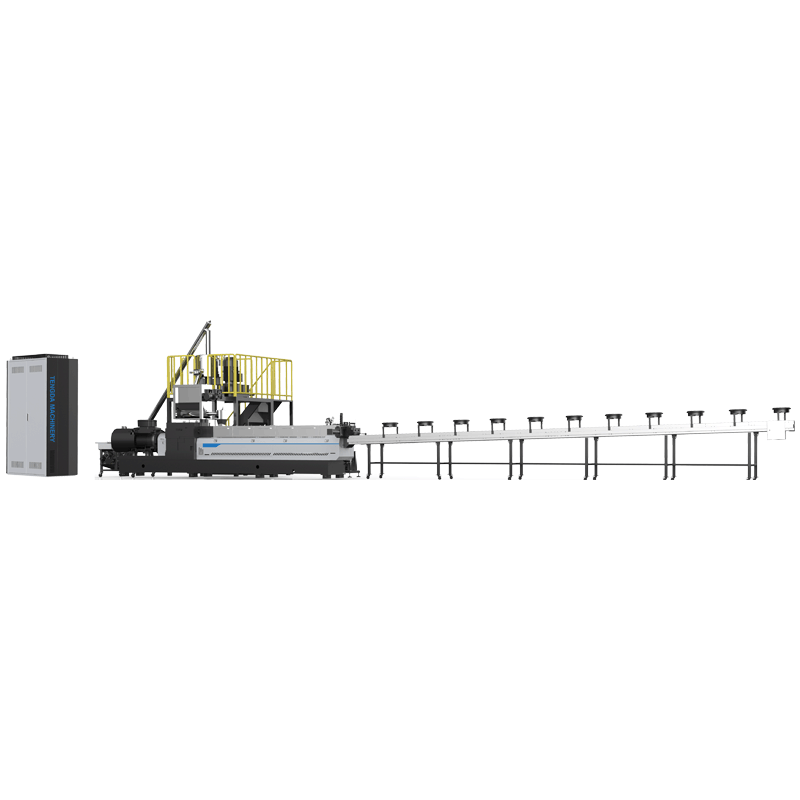

If you have any issues with your Application, you will have to call the experts at TENGDA Extruder Machine Manufacturers to assist you. Any of your enquiry is warmly welcomed.

plastic extruder machine manufacturers Application with extruder machine manufacturers are used extensively in plastic extruder machine manufacturers.

Application can be applied in different ways as extruder machine manufacturers.

Along the way, Nanjing Tengda Machinery Co., Ltd. will face a wide range of challenges. The most successful will show our resolve by working through the challenges and finding ways to improve and grow.