What is the working principle of the co-rotating parallel twin-screw extruder?

Due to the small center distance between the two screws of the co-rotating parallel twin-screw extruder, it is obviously impossible to use a large-diameter anti-return bearing. The bearing capacity of the anti-return bearing is related to its diameter, and the larger the diameter, the larger the bearing capacity. This contradictory situation is usually caused by the use of several small-diameter anti-return bearings in series to jointly bear a strong axial force. If this method is used, it must be required that the load on each thrust bearing should be uniform and the same, otherwise, it will bear a large axial force. The bearing is damaged in advance due to overloading, and the load it should bear is added to other bearings to make it overloaded. This continuous damage will eventually lead to the damage of the entire mechanical equipment and cannot work normally.

The conical twin-screw extruder has an included angle due to the arrangement of the two screws, so the two output shafts of the transmission gearbox have a large center distance. Sufficient to resist the axial force created by the head pressure. It can be seen from this that the transmission system structure of the parallel twin-screw extruder is relatively complex. Compared with the transmission system structure of the conical twin-screw extruder, the manufacturing cost of the gearbox is high and the maintenance is more complicated.

Many of us have heard about Application and seen some of these units in operation in plastic extruder machine manufacturers, extruder machine manufacturers and plastic extruder machine manufacturers spaces.

Nanjing Tengda Machinery Co., Ltd. also values the time, skills, and expert opinions of our staff. We are committed to providing fair and living wages, reasonable, structured work schedules, and clear duties and spheres of rights and responsibilities for each team member.

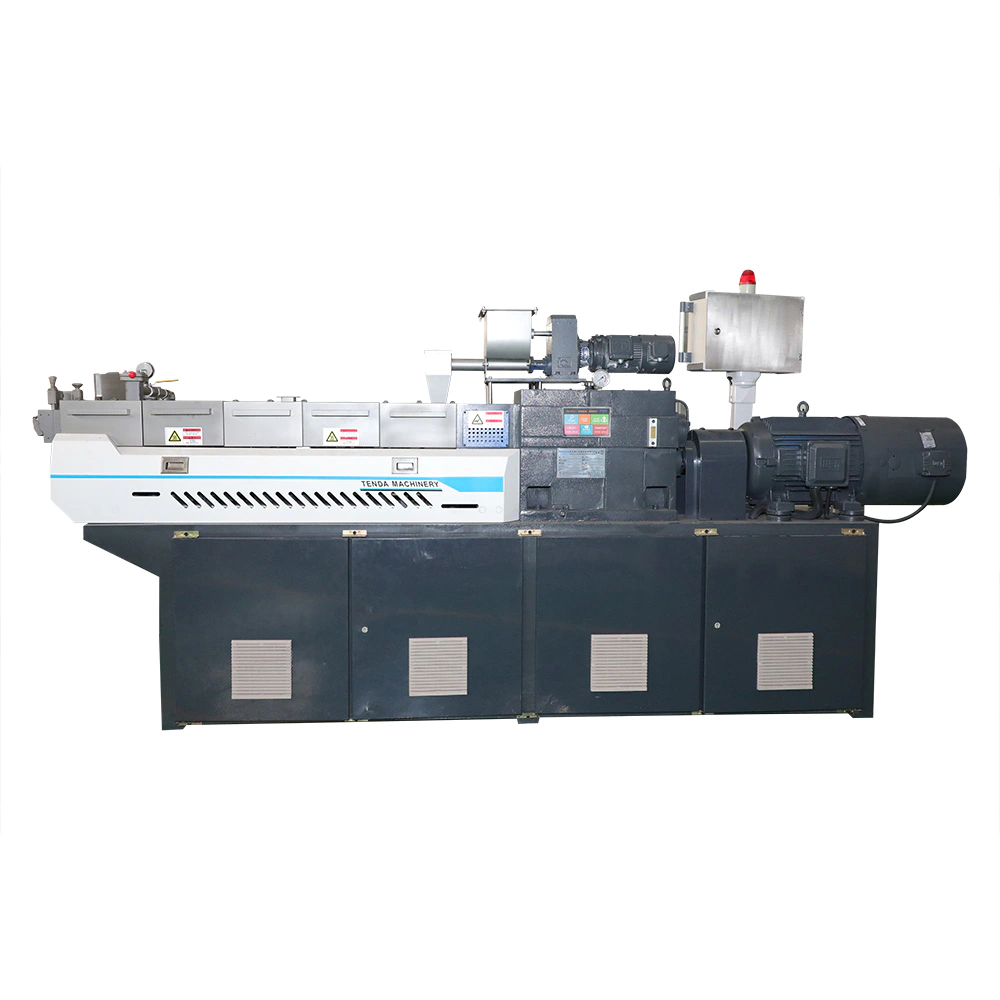

Nanjing Tengda Machinery Co., Ltd., which prides itself on Application for applying in different ways.

Making a few technical tweaks to the way you structure and distribute Application could be the difference between an engaging, thought-provoking product and a perfunctory one.

Application has a great positive reflects from our dear customers.