What Makes Plastics Extruders Such a Versatile Option for Manufacturing?

What Makes Plastics Extruders Such a Versatile Option for Manufacturing?

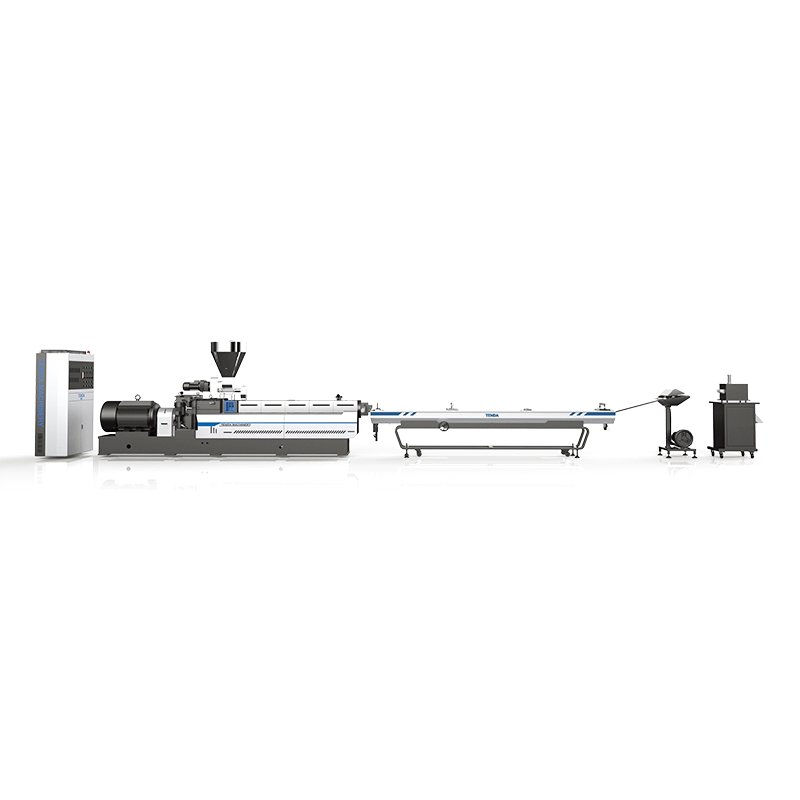

When it comes to manufacturing, there are a variety of different methods that can be used. One of the most versatile options is plastics extrusion. Plastics extruders are machines that have the ability to produce a wide range of products using different types of thermoplastic materials. This article will explore why plastics extruders are such a versatile option for manufacturing and some of the products that can be made using this method of production.

Understanding the Plastics Extrusion Process

Before delving into why plastics extruders are so versatile, it's important to understand the process by which they work. The plastics extrusion process begins with the melting of a thermoplastic material, which is then forced through a die to create a specific shape. The shape of the final product is determined by the shape of the die.

One of the key benefits of the plastics extrusion process is that it is highly customizable. The shape of the die can be altered to produce products in a wide range of sizes and shapes. This makes plastics extruders a versatile option for manufacturing.

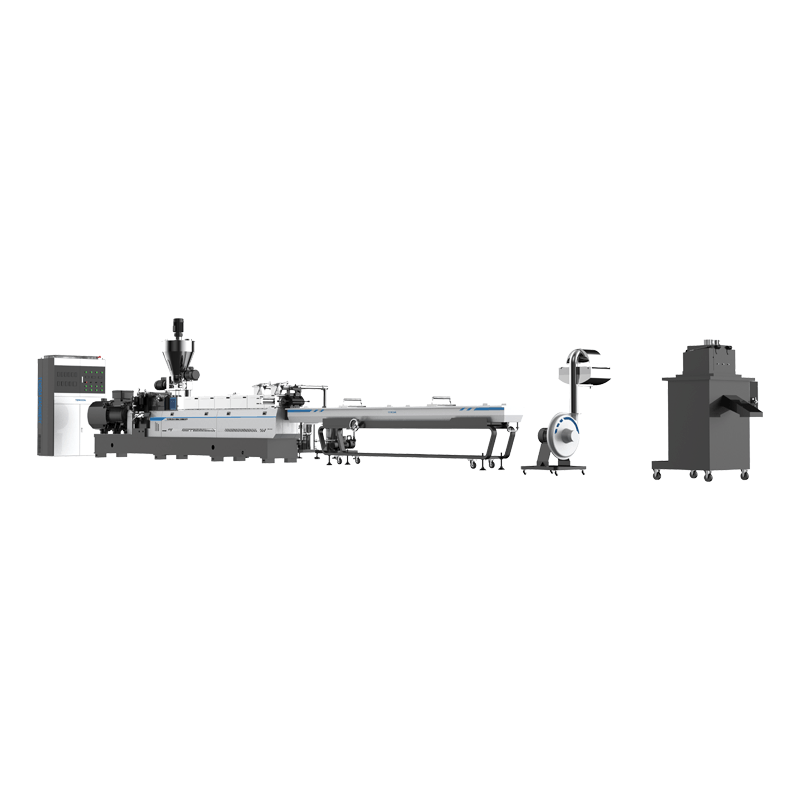

Versatility of Plastics Extruders

There are a variety of factors that contribute to the versatility of plastics extruders. Some of the key factors include:

1. Ability to produce a wide range of products C Plastics extruders can be used to produce a wide range of products, from simple tubing to complex profiles and shapes. This versatility is made possible by the ability to customize the shape of the die to suit the specific needs of the product.

2. Compatibility with different types of thermoplastic materials C Plastics extruders can be used with a variety of different thermoplastic materials, including PVC, polyethylene, polystyrene, and more. This means that manufacturers can choose the best thermoplastic material for their specific application.

3. Low cost of production C Plastics extrusion is a cost-effective method of production, which makes it an attractive option for small and large scale manufacturing. Because the process is highly automated and requires minimal human intervention, it's possible to produce products quickly and at a low cost.

4. Ability to produce both simple and complex shapes C Plastics extrusion can be used to produce both simple and complex shapes, which makes it a versatile option for manufacturers looking to produce a wide range of products.

5. High level of precision C Plastics extruders are able to produce products with a high level of precision, which is important for applications where accuracy is critical.

Products Made Using Plastics Extrusion

Because of the versatility of plastics extruders, there are a wide range of products that can be made using this method of production. Some of the most common products include:

1. Tubing C The plastics extrusion process lends itself well to the production of tubing, which is used in a variety of industries including medical, automotive, and construction.

2. Profiles C Plastics extrusion can be used to produce extruded profiles, which are used in a variety of applications including window frames, door frames, and trim.

3. Filament C The 3D printing industry relies heavily on plastics extruders to produce filaments, which are then used to create 3D printed products.

4. Strips C Plastics extrusion can also be used to produce strips, which are used in a variety of applications including weather stripping, sealing, and gasketing.

5. Sheets C Plastics extrusion is often used to produce plastic sheets, which can be used in a variety of applications including packaging, signage, and consumer goods.

Conclusion

In conclusion, plastics extruders are a versatile option for manufacturing because they offer a range of benefits including the ability to produce a wide range of products, compatibility with different types of thermoplastic materials, low cost of production, ability to produce both simple and complex shapes, and a high level of precision. Because of these benefits, plastics extruders are becoming an increasingly popular choice for manufacturers looking for a cost-effective and highly customizable method of production.