What Makes Steel Extruders Ideal for Heavy-Duty Applications?

If you are in the construction, manufacturing, or automotive industry, you know the importance of having high-quality equipment and tools that can withstand heavy-duty applications. One of the most common materials used in heavy-duty applications is steel. Steel is known for its durability, strength, and resistance to wear and tear. In this article, we will discuss why steel extruders are ideal for heavy-duty applications.

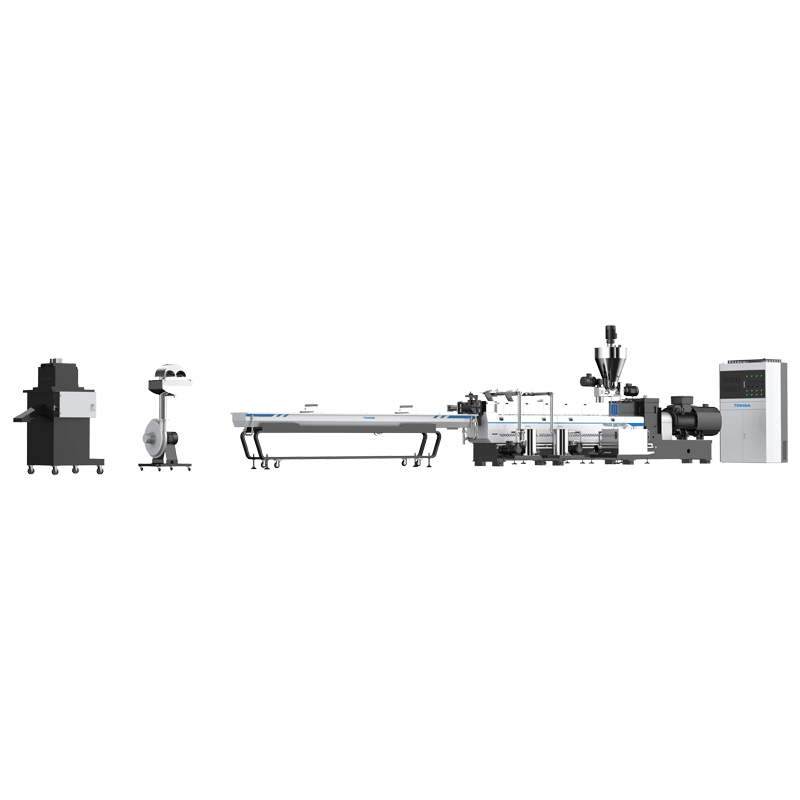

What are Steel Extruders?

Steel extruders are machines designed to shape steel into various forms and shapes. The process involves melting steel into a liquid form and pushing it through a die to create a specific shape or profile. The resulting product is a solid steel piece with the desired profile or shape. Steel extruders are commonly used in industries such as construction, automotive, aerospace, and manufacturing.

Advantages of Steel Extruders in Heavy-Duty Applications

1. Strength and Durability

One of the main advantages of steel extruders is their strength and durability. Steel is known for its high tensile strength, which makes it ideal for heavy-duty applications. Steel extruders have the ability to create complex shapes and profiles that can withstand high levels of stress and pressure. This makes them ideal for use in heavy construction and manufacturing applications where strength and durability are critical.

2. Resistance to Wear and Tear

Another advantage of steel extruders is their resistance to wear and tear. Steel is a highly resistant material that can withstand exposure to harsh conditions and environments. Steel extruders are designed to create steel pieces that can resist corrosion, abrasion, and rust, which means they can last for a long time without losing their strength or durability.

3. Customization

Steel extruders offer a high degree of customization when it comes to shaping steel. They can create a wide range of shapes and profiles that can be tailored to meet specific needs. This means that steel extruders can be used to create components and parts for machines and equipment that require precise specifications. This makes them ideal for use in industries where customization is important, such as the automotive and aerospace industries.

4. Efficiency

Steel extruders are designed to be extremely efficient in terms of production. They are capable of producing large quantities of steel pieces in a short amount of time, which means they can help companies reduce their production costs. This makes them ideal for use in industries where high production volumes are required, such as the construction and manufacturing industries.

5. Cost-effective

Despite being powerful and producing high-quality steel pieces, steel extruders are cost-effective. They can be used to create large volumes of steel pieces quickly, which means that companies can reduce their production costs. This makes them ideal for use in industries where cost-effectiveness is important, such as the construction and manufacturing industries.

Conclusion

In conclusion, steel extruders are ideal for heavy-duty applications due to their strength, durability, resistance to wear and tear, customization, efficiency, and cost-effectiveness. They are capable of shaping steel into various forms and profiles, making them ideal for use in industries such as construction, automotive, aerospace, and manufacturing. If you are looking for a machine that can shape steel into the desired form or profile, then a steel extruder is the best option for you.