Why does the twin-screw extruder have a vacuum leak? Its heating and temperature control measures have these!

Reasons for vacuum blowing of twin-screw extruder:

1. Screw factors

Multi-stage designs are commonly used in twin-screw extruders. The advantage of this design is that the outlet is at normal pressure and the material will not flow out. However, when the feed rate of the first screw is greater than that of the second screw, the melt in the extruder will flow back. At this time, it is necessary to reduce the feed amount of the first stage or increase the feed amount of the second stage.

2. Process conditions

Changing the process conditions is a simple and quick way to solve the problem of vacuum leaking in the twin-screw extruder. Examples include cooling, increasing friction and shear stress along the barrel or screw, and increasing friction or viscosity along the barrel surface to increase material delivery.

If the problem cannot be solved by changing the processing conditions, other methods must be adopted, such as redesigning the screw, reducing the resistance of the machine head, lengthening the screw and steel barrel, or installing a gear pump between the extruder and the machine head. Installing a gear pump can solve the discharge problem, but it is more expensive than a new screw.

3. The diverter element of the exhaust port

When the sheet was extruded with a newly polished 150mm twin-screw extruder with a feeder, it was impossible to produce a qualified product, and the screw could not be seen at all. This shows that there is a big problem in the design of the shunt element, and it is necessary to remove the shunt element to check the fullness of the spiral groove.

Heating and temperature control of the twin-screw extruder;

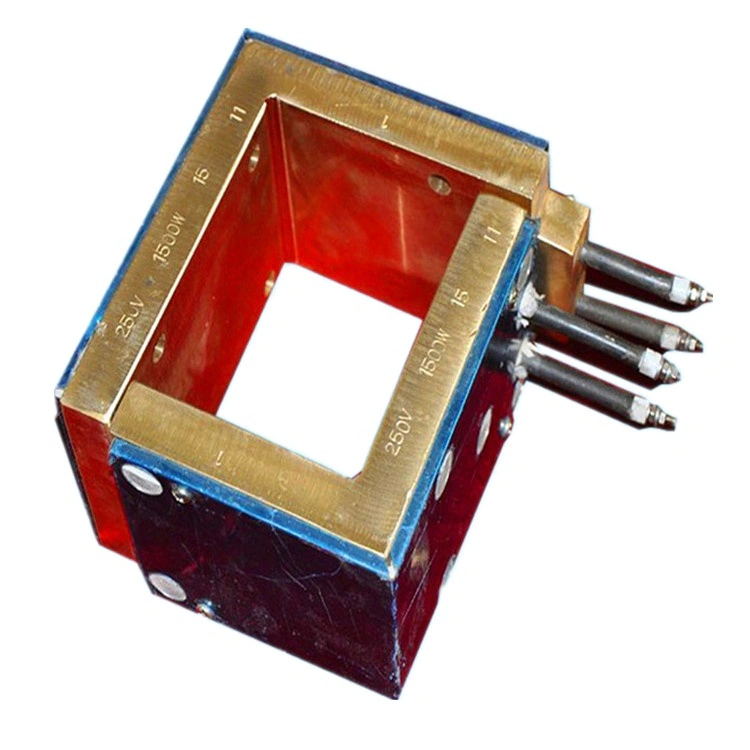

1. The high-efficiency heating element conducts heat from the inside to the outside, which greatly improves the heating speed of the twin-screw extruder. It has strong advantages for production task switching in small batch production.

2. The newer twin-screw extruder barrel adopts special seals for pure mechanical sealing, the working pressure can reach about 450bar, and it is corrosion-resistant, eliminating the risk of leakage.

3. The axial cooling channel has a larger aperture and flow rate and a higher flow rate, so the cooling efficiency is higher and the temperature control accuracy is easier to control; the axial water channel uses two cooling channels for uniform reciprocating heat exchange, avoiding the conventional water channel And the uneven cooling rate caused by the radial waterway, especially effectively reducing the deformation of the cylinder;

4. In unit time, the heating power of the twin-screw extruder is low, starting 7000 hours per year. Compared with the same specification, it can save about 27% of electric energy every year.

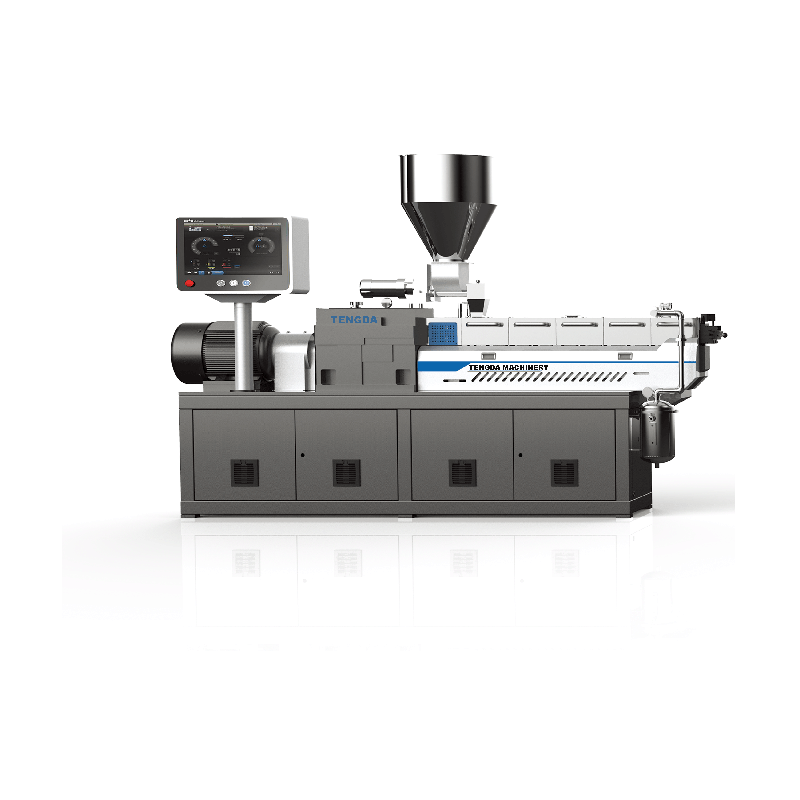

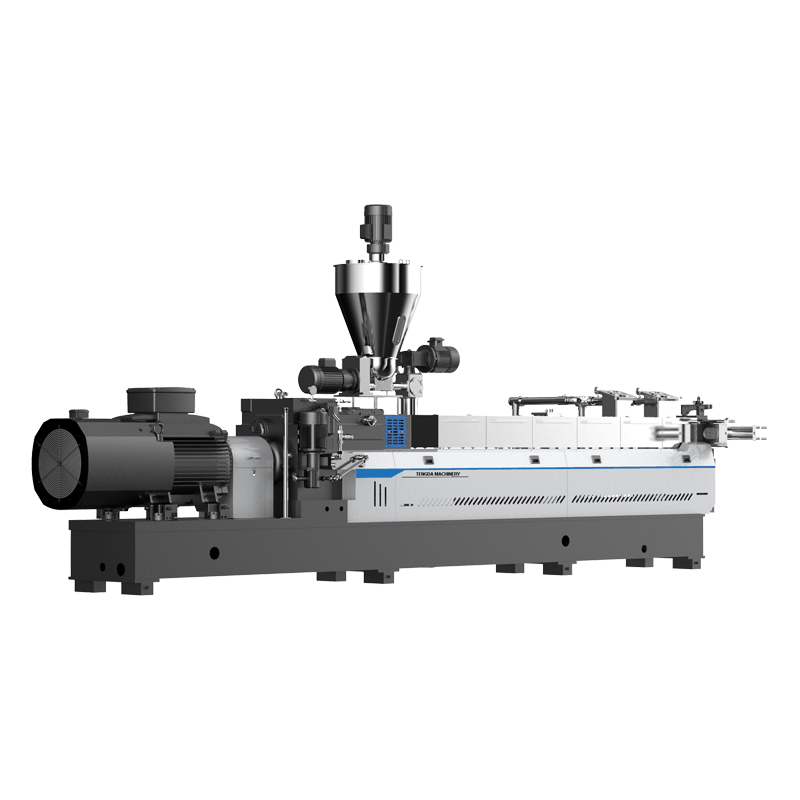

After reading the introduction of TENGDA Plastic Extruder Machine Manufacturers, do you know more about twin-screw extruders? If you encounter any problems during use, you can consult TENGDA Plastic Extruder Machine Manufacturers!

are important in ensuring plastic extruder machine manufacturers, and the machine is utilised by everyone from extruder machine manufacturers to plastic extruder machine manufacturers.

Nanjing Tengda Machinery Co., Ltd.’s purpose is to create superior value for our customers, employees, communities and investors through the production, conversion, delivery and sale of energy and energy services.

TENGDA is one of the top brands in their class when it comes to Application and extruder machine manufacturers. If you check online, TENGDA is often rated high and reviewed with much praise. we would be very pleased to receive your inquiry.

We create a group of experts to promote the quality standard and innovative technology of Application.

Forging an tight connection starts with understanding your potential customers and catering to their needs on Application, both with a quality product and impactful plastic extruder machine manufacturers.