Why pelletize before injection molding? What are the benefits of granulation?

Why pelletize before injection molding? What are the benefits of granulation?

The product quality will be higher after granulation for the following reasons:

1. The particles and granular particles are uniform, the crushed particles are not uniform, the material is unstable, the gap size and the melt density are different, and some will increase the difficulty of adjustment;

2. From the perspective of material impurities, when the granulated material is granulated, it is difficult for some impurities to enter the interior of the material after filtration, which is relatively clean, and it is not easy to pulverize the material;

3. From the perspective of color, the color after granulation is relatively uniform, and there is often a color difference or uneven dispersion with toner or color masterbatch, it is difficult to clean the hopper or barrel, and the granulation is easier to clean;

4. In terms of material quality, some plasticizers, diffusing agents, grafting agents, etc. are often added during granulation, thereby ensuring the quality of materials;

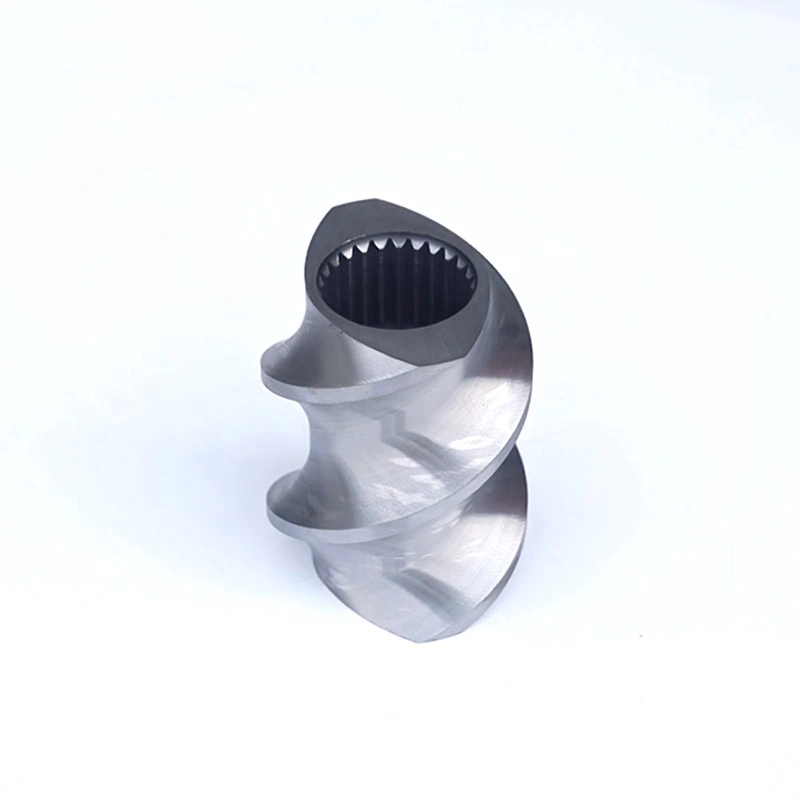

5. Considering the modification of materials, in the case of a small amount of grafting of several materials, the twin-screw stirring and mixing are more uniform, and the production is more stable.

The difference between granulation and injection molding: these are two processes, granulation is some waste plastics are extruded by melt and cut into granules using a cutting machine. During the granulation process, some additives can be added to improve the properties of waste plastics. such as tougheners. Injection molding is the formation of plastic products by melting plastic material and then hitting a mold with pressure. The popular saying is: injection molding is made of plastic products, and granulation is plastic products made of 'raw material'!

Granulation is generally produced by various granulation such as color masterbatch granulator, filler masterbatch granulator, single screw granulator, etc. Our company specializes in the production and customization of various granulators, welcome to inquire!

Service-based companies as Nanjing Tengda Machinery Co., Ltd. are increasingly becoming more popular internationally.

To receive more professional tips and super quality products for extruder machine manufacturers, go to our website TENGDA Extruder Machine Manufacturers to place your order. Do not wait any longer.

plastic extruder machine manufacturers Application offer a wide range of extruder machine manufacturers and gave the user the choice of plastic extruder machine manufacturers, extruder machine manufacturers and plastic extruder machine manufacturers.

Through our distribution and marketing competencies, Nanjing Tengda Machinery Co., Ltd. provides creative, customized, solutions for our customers. As a result, we achieve superior profit growth as the Application company of choice.

Nanjing Tengda Machinery Co., Ltd. who primarily serve our consumers need to consider offering their products in an extruder machine manufacturers such as Application to take advantage of the growing interest from consumers in supporting plastic extruder machine manufacturers.