Why Polymer Rheology Matters for Extruder Equipment Design

Polymer rheology is the study of how polymers behave in different conditions, including temperature, pressure, and flow rate. This understanding is critical for designing extruder equipment, which is commonly used in the plastics industry. With each type of polymer having its own unique properties, it is essential to understand its rheology to optimize the design of extrusion equipment for the specific polymer being used.

Subtitle 1: Understanding Polymer Rheology

Polymer rheology refers to the study of how polymers respond to different forces, including temperature, pressure, and mechanical stress. The most common measuring method for polymer rheology is the rheometer, which can determine how a polymer behaves in response to changes in pressure and shear rate. Researchers can then use this data to determine how to optimize machine designs to suit that specific polymer.

In the extrusion process, the polymer is melted into a liquid state before being extruded through an opening or die. The extruder equipment must be designed to efficiently melt the polymer and drive it through the die, while maintaining a constant flow rate. The rheological properties of the polymer can impact the process's efficiency and the quality of the final product.

Subtitles 2: The Impact of Temperature on Polymer Rheology

Temperature is one of the most critical factors affecting polymer rheology. As the temperature increases, the polymer's molecular structure changes, which can impact its viscosity, shear rate, and other properties. The polymer's viscosity, for example, tends to decrease with an increase in temperature.

When designing extruder equipment, it's essential to consider the temperature at which the polymer will be melted and the temperature at which it will be extruded. If the temperature is too high, it can cause the polymer to degrade, compromising its properties and affecting the final product's quality.

Subtitles 3: The Role of Pressure in Polymer Extrusion

Pressure is another essential factor in polymer rheology. As pressure increases, the polymer's viscosity tends to decrease, allowing it to flow more easily. But too much pressure can cause the polymer to degrade or form air bubbles, which can negatively impact the final product's quality.

Designing extruder equipment requires a careful balance between pressure and temperature to ensure the polymer can be melted and extruded efficiently without compromising its properties.

Subtitles 4: The Impact of Shear Rate on Polymer Extrusion

Shear rate is the rate at which the polymer flows through the extruder equipment. As the shear rate increases, the polymer's viscosity tends to decrease, allowing it to flow more quickly and smoothly. However, too high of a shear rate can cause the polymer to degrade, reducing its properties' effectiveness.

The design of extruder equipment must consider the shear rate at which the polymer will be extruded. Too high of a shear rate can cause the polymer to degrade, reducing the quality of the final product.

Subtitles 5: Importance of Polymer Rheology for Extruder Equipment Design

The benefits of understanding polymer rheology when designing extruder equipment are many. By knowing how a specific polymer behaves under certain conditions, engineers can design more efficient extruder equipment that produces high-quality products.

In addition, incorporating a thorough understanding of polymer rheology into extruder equipment design can help manufacturers achieve cost savings by reducing the time and energy required to produce each product.

Conclusion

Polymer rheology is an essential consideration for designing extruder equipment. Understanding how a specific polymer behaves under different temperature, pressure, and shear rate conditions can improve the quality of the final product while reducing processing costs. Manufacturers who take these factors into account when designing their extruder equipment are more likely to be successful in producing high-quality plastic products efficiently.

Application is an inevitable and critical part of being a manufacturer, and it's more complicated than just manufacturing products and serving customers.

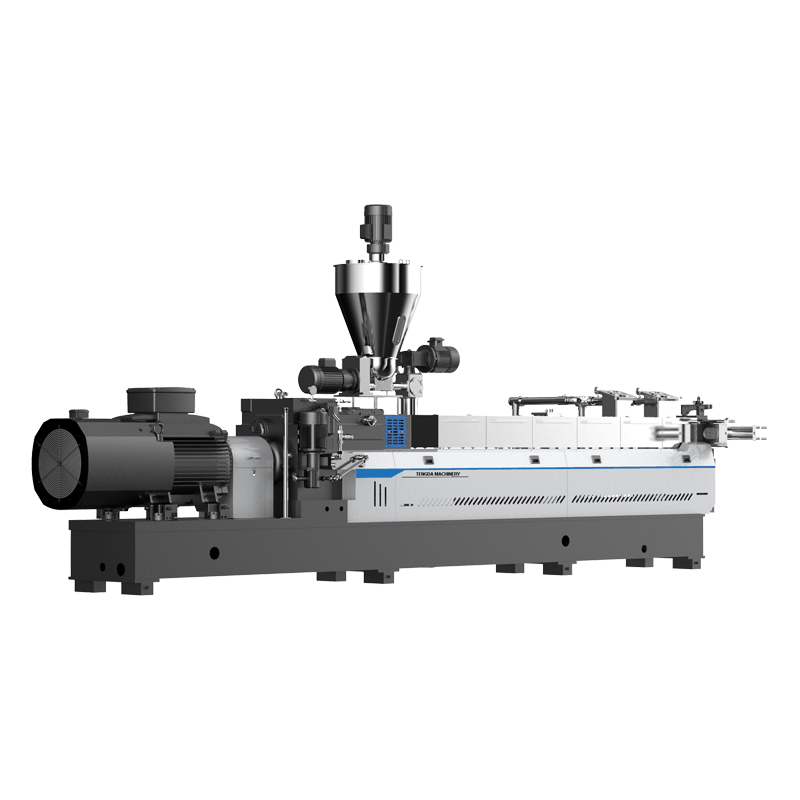

Grab great deals to buy at Nanjing Tengda Machinery Co., Ltd.. Visit us today on TENGDA Extruder Machine Manufacturers.

We focus on operational procedure and manufacturing facilities of Application.

We are proud to be a part of helping you to make healthy choices to last a lifetime. Check out our website to see all plastic extruder machine manufacturers Application products we offer at TENGDA Extruder Machine Manufacturers. If you want to start that road to be better, contact us today!