Working principle of twin screw extruder

Twin-screw extruders have the extruder principles of single-screw extruders: solids conveying, melting, pressurization and pumping, mixing, stripping and devolatilization, but not simply. The research on twin-screw extrusion theory started late, coupled with its many types, complex screw geometry, and complex extrusion process, which brought many difficulties to the research. On the whole, the research on the theory of twin-screw extrusion is still in the initial stage, which is said"Craft more than science".

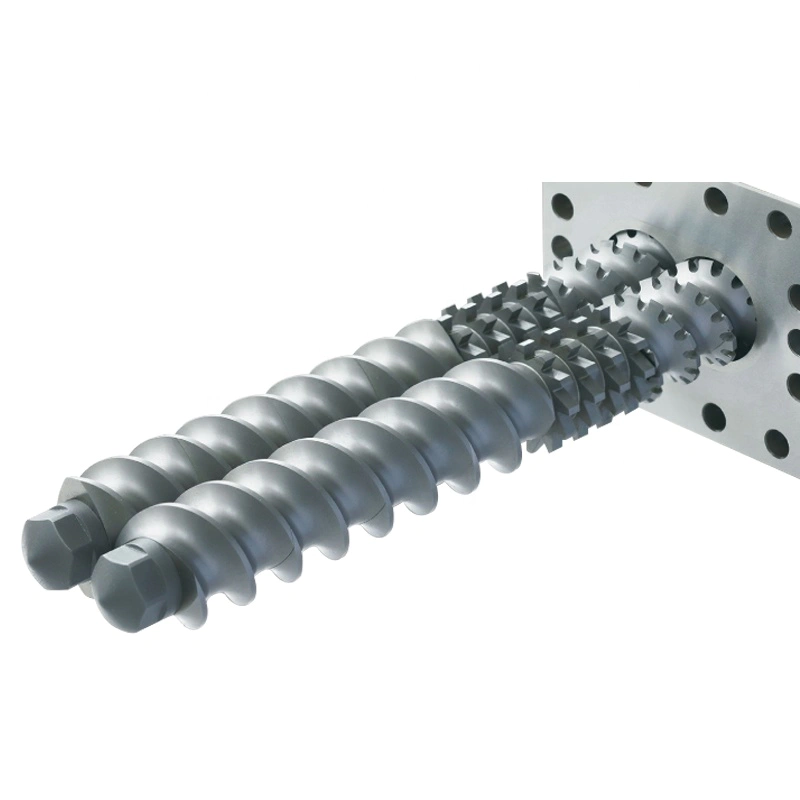

Extrusion molding by twin-screw extruder is a process in which a plastic material with a certain plasticity is continuously pressed out through a mouth under certain conditions to make it a product with a certain cross-sectional shape. During the advance of the rubber material along the screw, due to the results of mechanical and thermal effects, the viscosity and plasticity of the rubber material have changed to a certain extent, and it has become a viscous fluid. According to the change of the rubber material in the extrusion process, the working part of the screw is generally divided into three parts: the feeding section, the compression section and the extrusion section according to their different functions.

Co-rotating intermeshing twin-screw extruders are available in low-speed and high-speed types, the former mainly used for profile extrusion and the latter for specialty polymer processing operations. Self-cleaning extruder. High-speed co-rotating extruders have closely matched flight profiles. This kind of screw can be designed to have a relatively small screw gap, so that the screw has a closed self-cleaning effect. This twin-screw extruder is called a compact self-cleaning co-rotating twin-screw extruder. Close meshing extruder. Low-speed extruders have a closely intermeshing screw geometry in which the flight profile of one screw closely mates with the flight profile of the other screw, a conjugate screw profile.

The center distance between the two screws of the non-intermeshing twin-screw extruder is greater than the sum of the radii of the two screws.

In the counter-rotating twin-screw extruder, the gap between the two screw grooves of the closely-meshing counter-rotating twin-screw extruder is very small, so it can achieve positive conveying characteristics.

An increasing dependence on the use of Application extruder machine manufacturers has made numerous changes in the plastic extruder machine manufacturers industry over the past decades.

Nanjing Tengda Machinery Co., Ltd. promises you that you will be satisfied with our service.

The stability of the system, controllability of the extruder machine manufacturers process, and mobility of the machines provide with a flexible and reliable Application system.

With this competency, Nanjing Tengda Machinery Co., Ltd. provide high technology and assist customers to create added value and contribute to the development of producing Application.