The

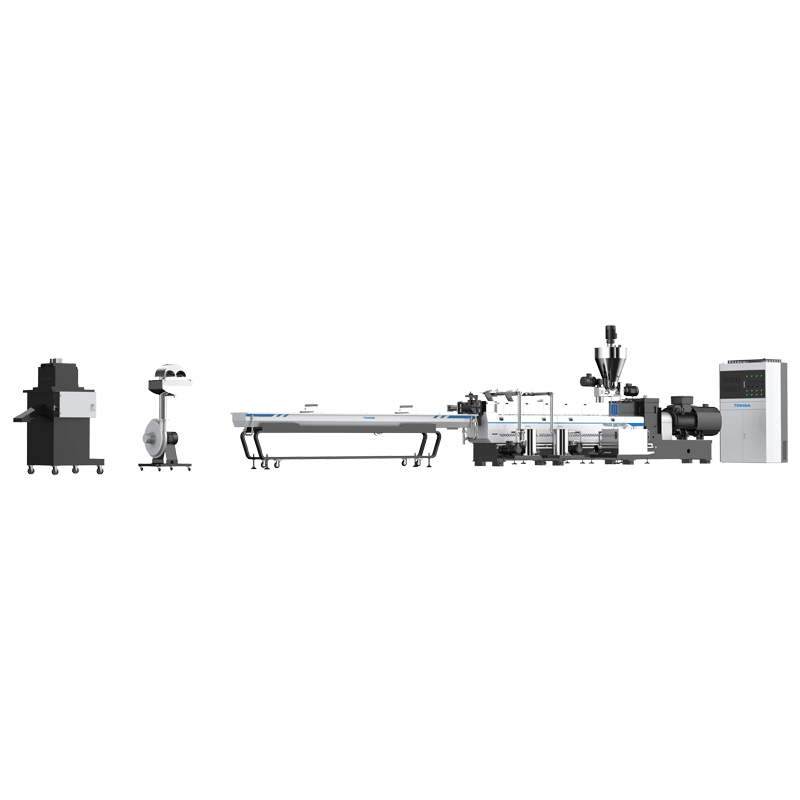

twin-screw extruder gearbox is a very important part of the parallel twin-screw extruder, and its structural design directly affects the normal operation of the entire machine system. Because the gearbox of the parallel twin-screw extruder relies on the large thrust of the output shaft to mix rubber, the center distance of the two screws is relatively small, and the output structure requires high rotation accuracy, so it is difficult to design and process this product. The twin-screw extruder was originally produced in food and plastic processing. In recent decades, its application range has been continuously expanded, and has been extended to rubber, coatings, petrochemical fiber, building materials, pulp, food, feed processing, and fluid machinery and other fields. The core of twin-screw extrusion machinery is the twin-screw mechanism. Because the twin-screw mechanism has obvious advantages in conveying, stronger mixing capacity, better self-cleaning performance, higher efficiency than the single-screw mechanism, and simpler structure than the three-screw and above multi-screw mechanism, it has been widely used. The twin-screw extrusion mechanism can be divided into parallel and non-parallel according to the position of the screw axis. Because the parallel twin-screw machine is manufactured, easy to install, and low in cost, it is widely used. This article mainly discusses the main features and applications of the parallel twin-screw mechanism. Twin-screw extruder The structure of the twin-screw extruder system varies according to the application field and operating characteristics. According to the direction of rotation, it is divided into counter-rotation and co-rotation. According to the form of meshing, it is divided into meshing type and non-meshing type. The meshing type is divided into full meshing type and partial meshing type. The spiral edge of one screw extends into the groove of the other screw like a wedge, and the material can basically not continue to enter the adjacent groove from the screw groove, but can only be forced by the screw groove. The groove flows into the groove of the other screw. As the screw continues to rotate, the material is repeatedly forced to turn, resulting in better shearing and mixing of the material. This structure has a good self-cleaning ability. Geometrically, the screw groove in the meshing zone is closed in the horizontal direction, or open, but it cannot be closed in the vertical direction, otherwise interference will occur. That is, the width of the screw groove must be designed to be greater than the width of the screw edge, and the road is blocked by another screw. The material is driven by the screw thread to move circularly through the gap of each part, and it also moves in the axial direction at the same time. When the material passes through the radial gap between the screws, it is as if the material passes through the nip of a roller, and is subjected to strong shearing and agitation. Due to the unique structure and working principle of the twin-screw mechanism, it has multiple functions such as extrusion, mixing or cutting, reaction, and extrusion molding. It can be made into a closed type with a material sealing effect, and it can also be fed to a place with pressure, which is convenient for feeding or unloading at any position; and because its shell and rotating shaft can be made into a water-cooled structure, it can also be used for high temperature Material conveying in the occasion, etc. Various mechanisms have twin screws that rotate in the same direction in terms of performance and application range. The speed of the screw edge and the screw groove are opposite, and the relative speed is greater than that of the reverse rotation, so the shear speed and shear force of the material in the meshing zone are also large. , The mixing effect is better than the counter-rotating twin screw. The co-rotating twin-screw extruder has no pressure at the screw engagement, no high shear zone, low wear of the screw and barrel, and is suitable for high-speed operation. However, the counter-rotating twin-screw extruder forms a higher pressure at the top of the meshing point, resulting in a larger shear rate. As the screw speed increases, the screw and barrel wear more and it is suitable for low-speed operation. In addition, the co-rotating twin-screw extruder equipment has good self-cleaning properties due to its own mechanism and can avoid clogging and feeding problems, while the non-rotating twin-screw equipment has only a certain degree of self-cleaning. As far as the number of thread heads is concerned, the positive displacement conveying capacity of the co-rotating twin-screw is greater when it has a single head, which can prevent materials from accumulating at the feeding port because they are too late to be conveyed forward, which affects the normal feeding. The cross-sectional area of u200bu200bthe screw groove of the double-headed positive thread element is smaller, and the shearing effect is soft. It is used in the occasions that require good mixing and conveying. It is currently used more. The cross-sectional area of u200bu200bthe screw groove of the three-head positive thread element is smaller, and its shearing effect is stronger, but the conveying capacity is low, and it is mostly used in the occasions that require high shear. To ensure vertical opening.

Finding a reliable solution for the Application

plastic extruder machine manufacturers not only supports operation of the entire system but also enhance the beauty of your workplace.

Nanjing Tengda Machinery Co., Ltd. also maintains a friendly, fair, and creative work environment, which respects diversity, new ideas, and hard work.

extruder machine manufacturers Application offer a wide range of plastic extruder machine manufacturers and gave the user the choice of extruder machine manufacturers, plastic extruder machine manufacturers and extruder machine manufacturers.

For optimal plastic

extruder machine manufacturers, choose a high-quality Application system and make sure a certified installer sets it up.

Deeper connections between TENGDA and Applicationare made when you go beyond the white lights of a corporate space.