Basics and Benefits of Extrusion Machines

Extrusion machines play a pivotal role in various industries, contributing significantly to the manufacturing of countless products we use daily. This comprehensive article delves into the fundamentals and advantages of extrusion machines, providing you with an in-depth understanding of their significance. Whether you are a novice or an experienced professional, this piece will enhance your knowledge and appreciation for this indispensable technology. So, let's dive in and explore the fascinating world of extrusion machines.

The Basics of Extrusion Machines

Extrusion machines are essential manufacturing tools designed to shape and form materials by forcing them through a die. At its core, the extrusion process involves the conversion of raw materials, typically in the form of pellets or powders, into a continuous profile of a desired shape. These machines are widely used in industries such as plastics, food, metals, and ceramics due to their efficiency and versatility.

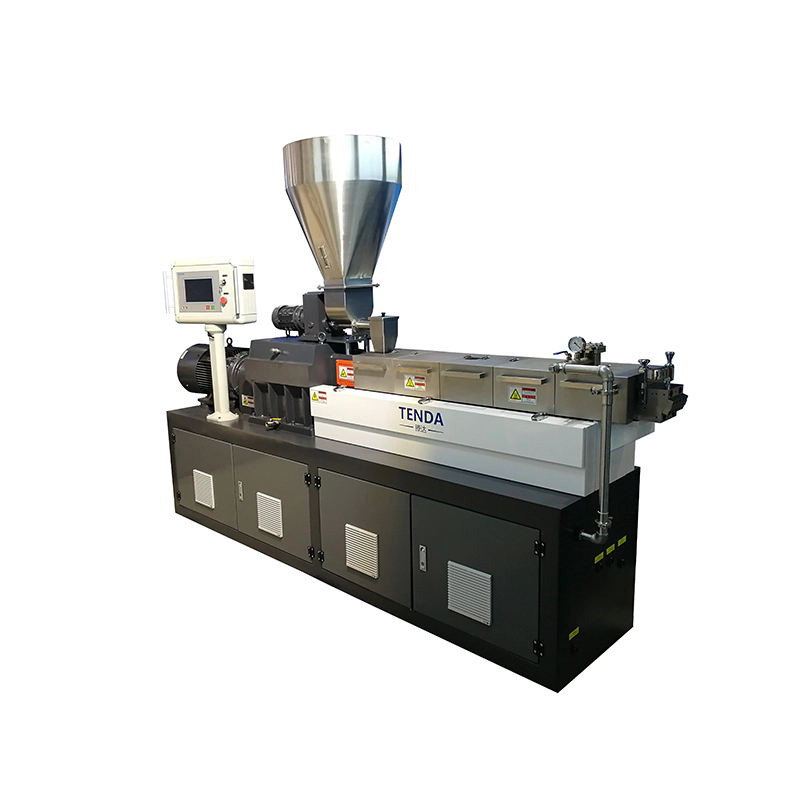

The fundamental components of an extrusion machine include a hopper, an extruder barrel, a screw, heaters, and a die. The process begins with feeding the raw material into the hopper, which then moves into the extruder barrel. The screw within the barrel rotates, transporting the material forward while simultaneously heating and mixing it. This action causes the material to melt and become pliable.

Once the material reaches the desired consistency, it is forced through the die, which imparts the final shape. The extruded product is then cooled and solidified before being cut or wound onto spools. This process allows for the continuous production of items with uniform cross-sections, such as pipes, sheets, and films.

One significant advantage of extrusion machines is their ability to process a wide range of materials, including thermoplastics, elastomers, food ingredients, and metals. This versatility makes them indispensable in various industries, from packaging to construction.

In summary, extrusion machines operate by converting raw materials into continuous profiles through a combination of heating, mixing, and shaping. Their flexibility and efficiency make them vital tools in modern manufacturing, enabling the mass production of diverse products essential to our daily lives.

Types of Extrusion Machines

Extrusion machines come in various types, each designed to meet specific manufacturing requirements. Understanding the different types of extrusion machines is crucial for selecting the right one for your application. The primary categories include single-screw extruders, twin-screw extruders, and ram extruders.

Single-screw extruders are the most common type of extrusion machine. They consist of a single screw within the barrel, which is responsible for transporting, melting, and mixing the material. These machines are highly versatile and can process a wide range of materials, including thermoplastics and elastomers. Single-screw extruders are commonly used in the production of pipes, profiles, and films.

Twin-screw extruders, on the other hand, feature two screws that rotate either in the same or opposite directions. This configuration provides better mixing and compounding capabilities, making twin-screw extruders ideal for applications requiring precise control over material properties. They are often used in the production of complex products such as multilayer films, food items, and pharmaceutical formulations.

Ram extruders are specialized machines used primarily for high-viscosity materials such as metals and ceramics. Unlike screw-based extruders, ram extruders use a piston or ram to force the material through the die. This type of extrusion machine is ideal for producing high-precision parts and profiles used in industries like aerospace and automotive.

In addition to these primary categories, several specialized extrusion machines are designed for specific applications. For example, blown film extruders are used to produce thin plastic films for packaging, while sheet extruders are utilized to manufacture flat plastic sheets for various industrial uses.

When selecting an extrusion machine, it is essential to consider factors such as material type, product specifications, and production volume. Understanding the different types of extrusion machines and their unique capabilities can help you make an informed decision, ensuring optimal performance and efficiency in your manufacturing process.

Benefits of Using Extrusion Machines

Extrusion machines offer numerous benefits that make them indispensable in modern manufacturing processes. Their ability to produce high-quality products with consistent properties has made them a preferred choice across various industries. Here are some of the key advantages of using extrusion machines.

One of the primary benefits of extrusion machines is their efficiency in producing continuous profiles. Unlike traditional manufacturing methods that involve separate steps for shaping and forming, extrusion machines can create a continuous flow of material, reducing production times and increasing output. This efficiency translates to cost savings and improved productivity for manufacturers.

Another significant advantage is the ability to process a wide range of materials. Extrusion machines can handle thermoplastics, elastomers, metals, and even food ingredients, making them versatile tools for diverse applications. This flexibility allows manufacturers to produce a broad spectrum of products, from pipes and sheets to food items and pharmaceutical formulations.

The consistent quality of extruded products is another notable benefit. Extrusion machines provide precise control over parameters such as temperature, pressure, and material flow, ensuring uniformity in the final product. This consistency is crucial in industries like packaging and construction, where product quality directly impacts performance and safety.

Extrusion machines also enable the production of complex shapes and profiles that would be challenging to achieve with other manufacturing methods. The use of custom dies allows manufacturers to create intricate designs and unique cross-sections, expanding the possibilities for innovative product development.

In addition to these technical benefits, extrusion machines are also environmentally friendly. They generate minimal waste during the production process, and many materials used in extrusion can be recycled, reducing the overall environmental footprint. This sustainability aspect is increasingly important as industries strive to minimize their impact on the environment.

Overall, the benefits of using extrusion machines are multifaceted, encompassing efficiency, versatility, quality, and sustainability. These advantages make extrusion machines a valuable asset in modern manufacturing, driving innovation and supporting the production of high-quality, diverse products.

Applications of Extrusion Machines

Extrusion machines play a crucial role in various industries, enabling the production of an extensive range of products. Their versatility and efficiency make them suitable for numerous applications, from packaging to automotive manufacturing. Understanding the diverse applications of extrusion machines highlights their significance in modern industrial processes.

In the plastics industry, extrusion machines are used to create a wide array of products, including pipes, profiles, and films. These plastic products are essential in construction, automotive, and consumer goods sectors. For instance, PVC pipes produced through extrusion are extensively used in plumbing and irrigation systems due to their durability and corrosion resistance.

The packaging industry also relies heavily on extrusion machines. They are used to produce films, sheets, and containers that are integral to packaging solutions. For example, blown film extrusion machines create thin plastic films used in packaging applications such as bags, wrappers, and shrink films. These films provide protective barriers for food and other goods, extending shelf life and ensuring product safety.

In the food industry, extrusion machines are used to manufacture various food products, including snacks, cereals, and pasta. The process of extrusion cooking involves mixing and cooking the food ingredients within the extruder, followed by shaping them through a die. This method allows for the continuous production of uniform food items with consistent texture and flavor.

The pharmaceutical industry also benefits from extrusion technology. Pharmaceutical extrusion machines are used to produce drug delivery systems such as tablets, pellets, and granules. This process ensures precise control over drug composition and release rates, enhancing the efficacy and safety of pharmaceutical products.

In the metals industry, extrusion machines are used to fabricate components with precise dimensions and complex shapes. Metal extrusion processes can produce items such as aluminum profiles, which are widely used in construction and aerospace applications. These profiles offer high strength-to-weight ratios, making them ideal for structural and lightweight designs.

Additionally, extrusion machines are employed in the production of advanced materials such as composites and ceramics. These materials are used in high-performance applications, including electronics, aerospace, and medical devices. Extrusion processes enable the creation of intricate geometries and tailored material properties, meeting the demanding requirements of these specialized fields.

In conclusion, the applications of extrusion machines are vast and varied, spanning industries such as plastics, packaging, food, pharmaceuticals, and metals. Their ability to produce high-quality, uniform products with diverse shapes and properties makes them indispensable in modern manufacturing processes.

Future Trends in Extrusion Technology

As technology continues to advance, extrusion machines are evolving to meet the changing demands of various industries. Emerging trends in extrusion technology are focused on enhancing efficiency, sustainability, and product quality. Understanding these trends provides valuable insights into the future of extrusion machines and their potential impact on manufacturing processes.

One significant trend is the adoption of Industry 4.0 principles in extrusion technology. Industry 4.0, also known as the Fourth Industrial Revolution, involves the integration of digital technologies and automation into manufacturing processes. In the context of extrusion machines, this trend is manifested through the use of advanced sensors, data analytics, and artificial intelligence (AI) to optimize operations.

For instance, smart extrusion machines equipped with sensors can monitor critical parameters such as temperature, pressure, and material flow in real time. The data collected is then analyzed using AI algorithms to identify patterns and optimize the extrusion process. This approach enhances efficiency, reduces downtime, and ensures consistent product quality.

Another emerging trend is the development of sustainable extrusion processes. As industries become more environmentally conscious, there is a growing emphasis on reducing waste and energy consumption. Innovations such as energy-efficient heating systems, recyclable materials, and closed-loop recycling processes are being incorporated into extrusion technology. These advancements aim to minimize the environmental impact of extrusion manufacturing, promoting sustainability and resource conservation.

Advancements in material science are also driving the evolution of extrusion technology. New materials with enhanced properties, such as biodegradable plastics and high-performance composites, are being developed for extrusion applications. These materials offer improved performance, reduced environmental impact, and expanded functionality, meeting the evolving needs of various industries.

The customization and flexibility of extrusion machines are also expected to improve. Innovations in die design and additive manufacturing techniques allow for the creation of complex and tailored geometries with greater precision. This trend enables manufacturers to produce unique, customized products with shorter lead times and reduced costs.

Additionally, the integration of extrusion technology with other manufacturing processes, such as 3D printing, is gaining traction. Hybrid manufacturing techniques that combine extrusion and additive manufacturing offer new possibilities for creating intricate and multi-material products. This approach leverages the strengths of both technologies, enabling the production of complex designs that were previously unattainable.

In summary, the future of extrusion technology is characterized by the adoption of digitalization, sustainability initiatives, advanced materials, customization, and hybrid manufacturing. These trends are poised to revolutionize extrusion processes, enhancing their efficiency, versatility, and environmental performance, and paving the way for innovative applications in various industries.

In conclusion, extrusion machines are indispensable tools in modern manufacturing, offering numerous benefits and applications across diverse industries. From the basics of how they operate to the various types available, understanding extrusion technology is essential for optimizing production processes. The advantages of using extrusion machines, including efficiency, versatility, and sustainability, underscore their significance in creating high-quality products.

The applications of extrusion machines are widespread, ranging from plastics and packaging to food, pharmaceuticals, and metals. Their ability to produce consistent and complex profiles with diverse materials makes them vital in meeting the demands of these industries. Furthermore, emerging trends in extrusion technology, such as Industry 4.0 integration, sustainability initiatives, and advancements in materials, highlight the ongoing evolution of this field.

As extrusion machines continue to advance, their impact on manufacturing processes will only grow, driving innovation and supporting the production of a wide range of high-quality products. Whether you are a seasoned professional or new to this technology, staying informed about the basics and benefits of extrusion machines will undoubtedly enhance your understanding and appreciation of their crucial role in modern industry.

As a entrepreneur, being trapped in a company under multiple quality problems never appealed to Nanjing Tengda Machinery Co., Ltd..

Compare the various types of that are available. At TENGDA Extruder Machine Manufacturers, the range is constantly being updated with new models, technical details and competitive prices.

A primary strategy is superior customer satisfaction. Nanjing Tengda Machinery Co., Ltd. constantly analyzes market needs around the world to develop a full range of products for different use.

Nanjing Tengda Machinery Co., Ltd. is an online resource for today's modern woman to live a green, healthy, and happy life. We offer Application, extruder machine manufacturers and more! Pls visit our site at TENGDA Extruder Machine Manufacturers to know more.

Producing with varied technical skills, Application can be used in a wide range of applications as plastic extruder machine manufacturers.