Breaking Barriers: Innovations in Plastic Compounding Machine Technology

Introduction

The plastic industry has experienced significant growth over the years, fueled by the increasing demand for plastic products across various sectors. Plastic compounding machines play a crucial role in the production process, as they enable the efficient mixing and compounding of different components to create high-quality plastic compounds. In recent years, there have been remarkable innovations in plastic compounding machine technology, breaking barriers and revolutionizing the industry. This article explores some of these advancements and their impact on the plastic compounding industry.

The Importance of Plastic Compounding Machines

Plastic compounding machines are essential in the plastic manufacturing process as they allow for the creation of specialized plastic compounds with enhanced properties. These machines combine different components, such as polymers, additives, and fillers, in precise proportions to achieve specific characteristics in the final product. Compounded plastics can offer improved strength, durability, resistance to heat and chemicals, electrical conductivity, and many other desirable attributes.

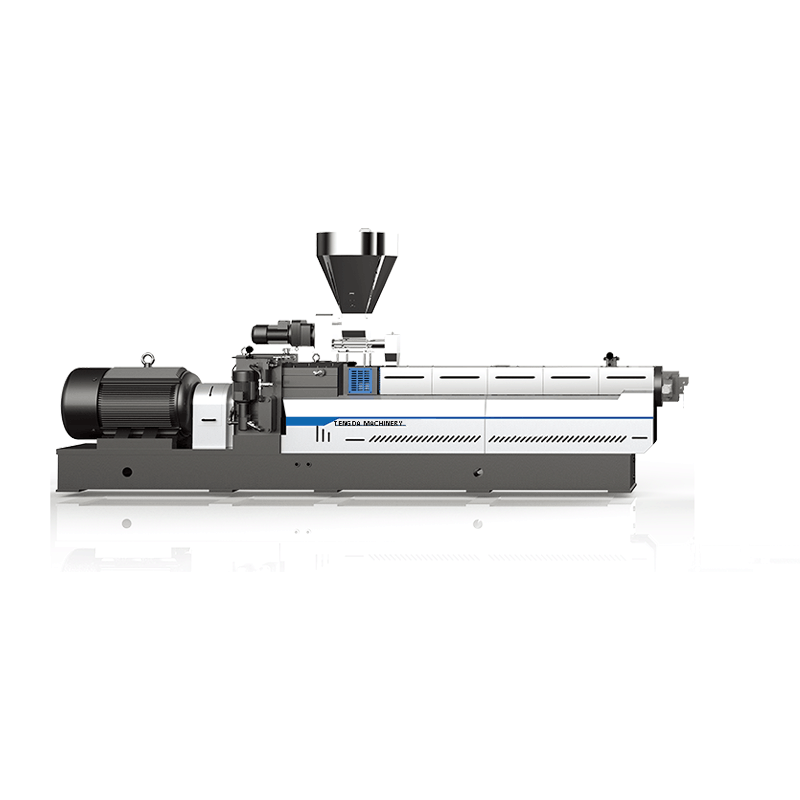

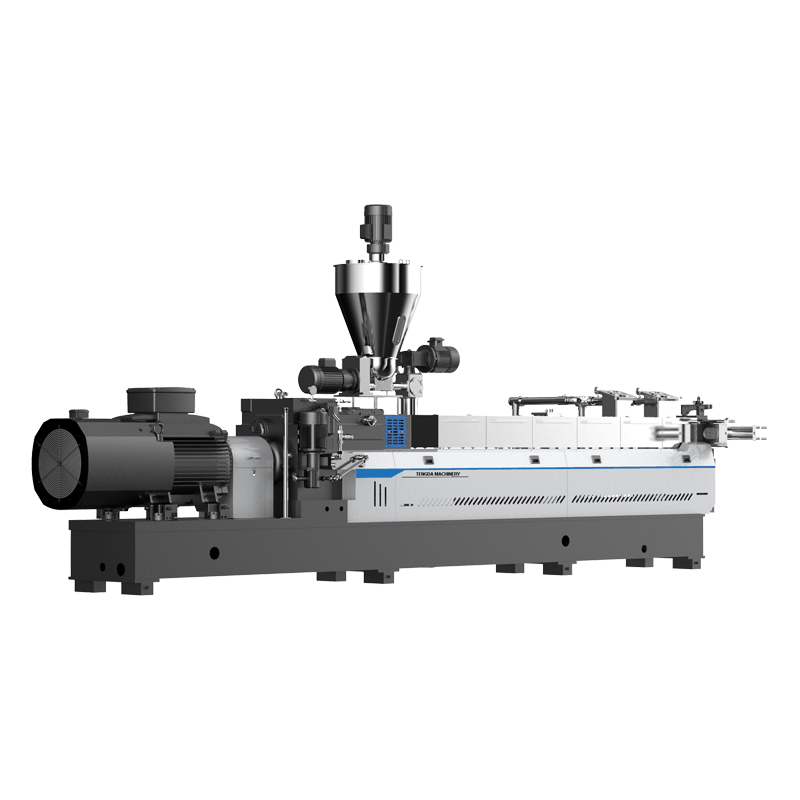

Increasing Efficiency with Advanced Extruder Designs

Extruders are the heart of plastic compounding machines, responsible for melting and mixing the raw materials. Recent advancements in extruder designs have significantly improved efficiency and productivity in plastic compounding. One such innovation is the development of co-rotating twin-screw extruders. These extruders provide excellent mixing capabilities, higher torque, and improved processing flexibility compared to traditional single-screw extruders. Co-rotating twin-screw extruders enable better control over the compounding process and result in more uniform and consistent plastic compounds.

Enhanced Process Control through Automation

Automation has transformed various industries, and plastic compounding is no exception. Advanced automation technologies have been integrated into plastic compounding machines, offering precise control and monitoring of the compounding process. Automation allows for real-time adjustments, ensuring consistent quality and reducing the risk of human error. Computerized control systems enable operators to set parameters such as temperature, screw speed, and fill rates, optimizing the compounding process for maximum efficiency and quality.

Improved Material Handling and Feeding Systems

Efficient material handling plays a crucial role in achieving consistent and high-quality plastic compounds. Recent innovations in plastic compounding machine technology have focused on improving material feeding and handling systems. Automatic feeding systems with gravimetric or volumetric controls ensure accurate and consistent material supply, reducing waste and improving overall efficiency. Additionally, advanced material handling systems are equipped with sensors and sophisticated algorithms that detect and automatically compensate for fluctuations in bulk density and flow rate, further enhancing accuracy and process control.

Advancements in Mixing and Dispersion Technologies

Uniform mixing and dispersion of additives and fillers are vital for achieving desired material properties in plastic compounds. Recent developments in plastic compounding machine technology have introduced innovative mixing and dispersion technologies that deliver superior performance. For example, the use of rotor-stator elements in extruders allows for more efficient and controlled dispersion of additives, resulting in improved product quality. Additionally, the incorporation of static mixers or dynamic kneading elements in the extruder barrel further enhances mixing efficiency, reducing processing times and energy consumption.

Summary

The plastic compounding industry is continuously evolving, thanks to groundbreaking innovations in machine technology. Advanced extruder designs, automation, improved material handling systems, and enhanced mixing and dispersion technologies have propelled the industry forward, breaking barriers and setting new standards for efficiency and product quality. These innovations not only improve the performance of plastic compounds but also contribute to waste reduction, energy efficiency, and overall sustainability. As the demand for specialized plastic compounds with tailored properties continues to grow, the advancements in plastic compounding machines will play a crucial role in meeting these needs and driving further progress in the industry. Through ongoing research and development, the future holds even more exciting possibilities for plastic compounding machine technology.

are important in ensuring plastic extruder machine manufacturers, and the machine is utilised by everyone from extruder machine manufacturers to plastic extruder machine manufacturers.

All you women out there looking for amazing to dazzle the world try Nanjing Tengda Machinery Co., Ltd. latest collections at TENGDA Extruder Machine Manufacturers. Try it!

Advanced technology and manufacturing equipment has enhanced the core quality of Application.

Nanjing Tengda Machinery Co., Ltd. has developed its range of products around its own market research, which discovers customers' precise needs.