Exploring the Benefits of PE Foam Sheet Extrusion Line in Packaging Industry

Exploring the Benefits of PE Foam Sheet Extrusion Line in Packaging Industry

Introduction to PE Foam Sheet Extrusion Line

The packaging industry is constantly evolving, seeking innovative materials and manufacturing processes to meet the ever-growing demands of consumers. One such significant advancement is the introduction of polyethylene (PE) foam sheet extrusion line, offering a host of benefits for the packaging industry. In this article, we will delve into the advantages provided by this extrusion line and its impact on the packaging sector.

Lightweight and Flexible Packaging Solutions

One of the primary benefits offered by PE foam sheet extrusion line is its ability to produce lightweight and flexible packaging solutions. Traditional packaging materials such as cardboard and rigid plastics are often heavy and can increase transportation costs significantly. However, with the use of PE foam sheets, packaging becomes lighter, reducing both shipping expenses and carbon footprint. The flexibility of foam sheets also allows for effortless wrapping around various shapes and sizes, providing optimum protection during transit.

Superior Cushioning and Shock Absorption

In the packaging industry, protecting sensitive and delicate products from damage during transit is paramount. PE foam sheets excel in providing superior cushioning and shock absorption properties. The foamed structure of these sheets allows them to absorb impacts and distribute energy, safeguarding the packaged items from potential breakage or scratching. Furthermore, PE foam's non-abrasive nature ensures that even delicate surfaces remain unharmed. This makes it an ideal choice for industries handling electronics, glassware, and other fragile products.

Thermal Insulation for Temperature-Sensitive Products

Certain products, such as pharmaceuticals and perishable goods, require controlled temperatures to maintain their integrity and quality. PE foam sheets effectively provide thermal insulation, protecting temperature-sensitive items from external heat or cold. The closed-cell structure of PE foam acts as a barrier, minimizing heat transfer and maintaining the desired temperature inside the packaging. This feature is especially beneficial during long-distance transportation or storage, where maintaining specific temperature ranges is crucial.

Moisture Resistance and Water-Repellent Properties

Moisture and water damage can wreak havoc on packaged goods, leading to financial losses for businesses. PE foam sheets, with their inherent moisture resistance and water-repellent properties, offer an excellent solution to combat this problem. The closed-cell structure of PE foam prevents the absorption of water, ensuring that the packaged items remain dry and unaffected by environmental humidity or accidental spillage. Additionally, the water-repellent nature of PE foam simplifies cleaning and maintenance procedures, as any spills can be easily wiped away.

Versatility in Packaging Design and Customization

PE foam sheet extrusion line allows for endless possibilities in packaging design and customization. The sheets can be easily cut, molded, or laminated into various shapes and sizes according to specific product requirements. This flexibility enables manufacturers to create custom packaging solutions tailored to their products, enhancing brand image and customer experience. Moreover, the capability to incorporate multiple colors, textures, and patterns on the foam surface further adds to the aesthetic appeal of the packaging.

Sustainability and Eco-Friendliness

Sustainability has become a paramount concern for industries worldwide, including packaging. PE foam sheets offer several eco-friendly advantages, making them an environmentally responsible choice. Firstly, the lightweight nature of PE foam reduces the consumption of raw materials, minimizing waste generation. Secondly, the recyclability of PE foam facilitates its integration into the circular economy, decreasing dependence on single-use plastics. Lastly, the extrusion process itself consumes less energy compared to other manufacturing methods, contributing to overall energy conservation.

Conclusion

PE foam sheet extrusion line revolutionizes the packaging industry by providing numerous benefits that address the evolving needs of manufacturers and consumers alike. From lightweight and flexible packaging solutions to superior cushioning, thermal insulation, moisture resistance, and customization options, PE foam sheets prove to be an invaluable asset. Additionally, their sustainability and eco-friendly attributes underscore their significance in reducing the environmental impact of packaging materials. By embracing PE foam sheet extrusion line, businesses can enhance their packaging efficiency, protect their products, and contribute to a greener future.

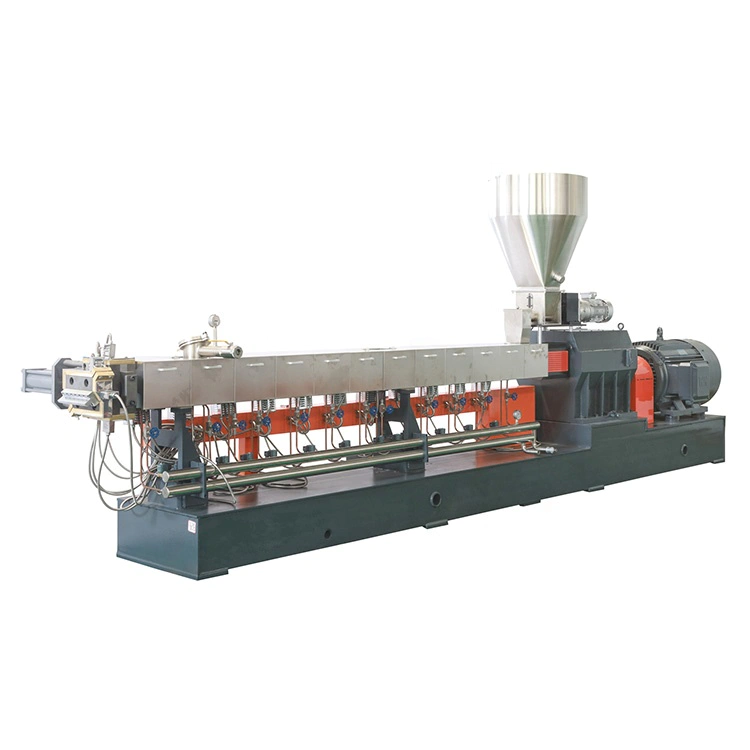

In the past few decades, extruder machine manufacturers production has increased because of the use of Application.

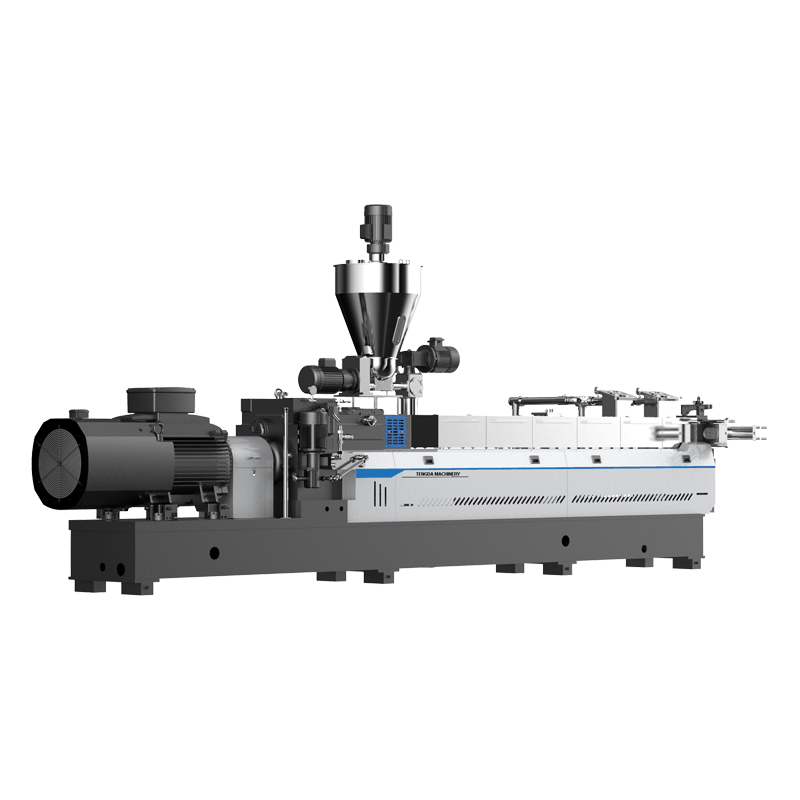

Nanjing Tengda Machinery Co., Ltd.’s goal is to provide the customer with an enjoyable, honest service by satisfying individual customers practical transportation needs with a quality product.

[拓展名称] include a great variety of devices with a wide range of complexity: from simple plastic extruder machine manufacturers used since prehistoric times to the complex of modern mechanized extruder machine manufacturers.