Masterbacth compounding

The processing of color masterbatch has strict requirements on the compounding process and equipment: the pigments and additives must be absolutely and uniformly dispersed and mixed into the base resin.

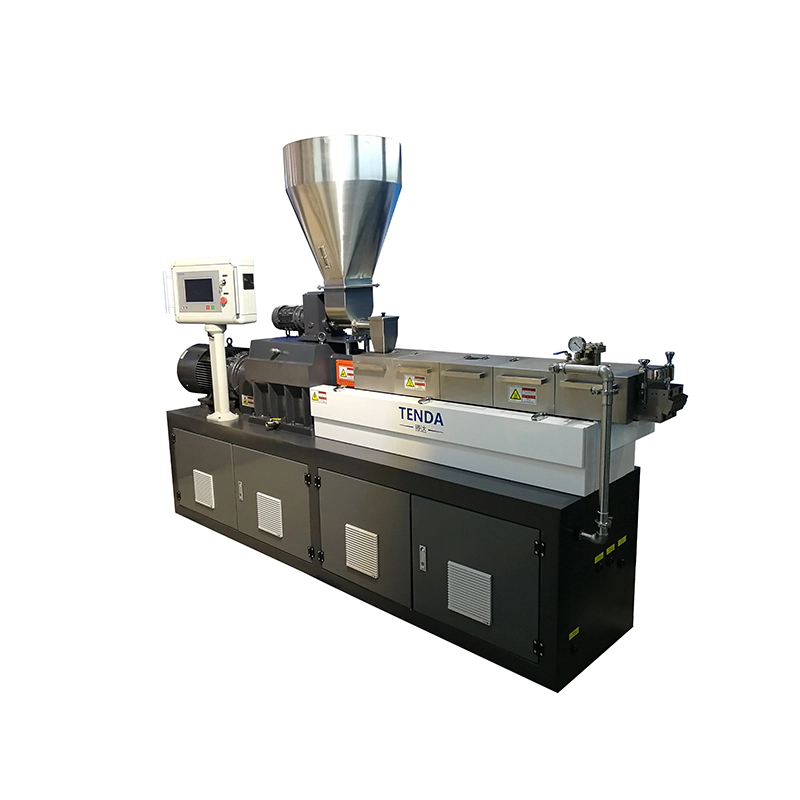

We have a wealth of process technology experience and know-how, according to your masterbatch formulation requirements, from raw material metering feeding, conveying, melting, dispersion, homogenization, devolatilization, pressure building, to filtration and pelletizing stages Customized design of process steps. Fully meet all your needs: a perfect compounding and extrusion system tailored for you.

The concept of masterbatch refers to the concentration of pigments or additives into the resin matrix. Masterbatches are generally standard-sized particles, but there are also micro-sized particles. According to different types of pigments, masterbatches are generally divided into white, black and colored. The production of masterbatch can adopt pre-mixing, sub-addition or color matching process.