Extruder Recycling: Best Practices for Implementing a Successful Recycling Program

Introduction to Extruder Recycling

Extruder recycling is a crucial component of any successful recycling program. With the ever-increasing need for sustainable practices and the growing problem of plastic waste, implementing an efficient and effective recycling program is essential. The extruder recycling process plays a vital role in minimizing waste, conserving resources, and reducing the environmental impact of plastic materials. In this article, we will delve into the best practices for implementing a successful extruder recycling program and explore the various aspects involved.

The Importance of Extruder Recycling

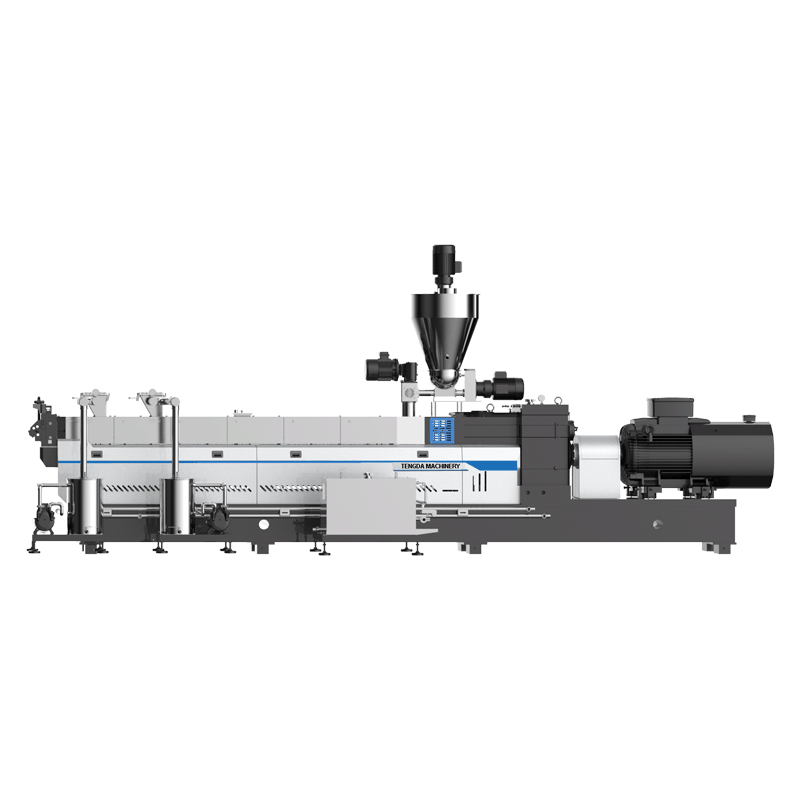

Extruder recycling is an essential part of the circular economy, where materials are continuously recycled and repurposed instead of ending up in landfills or incinerators. Plastic extruders are widely used in the manufacturing industry to shape raw plastic materials into various forms, such as pipes, sheets, and films. However, during this process, excess plastic waste and leftover materials are generated. Without proper recycling measures in place, this waste can accumulate and contribute to environmental pollution.

By implementing a successful extruder recycling program, companies can minimize the production of new plastic, reduce energy consumption, and decrease greenhouse gas emissions. Additionally, recycling plastic waste through the extruder process helps conserve valuable resources, as the recycled material can be used to create new products. This reduces the demand for virgin plastics and promotes a more sustainable approach to manufacturing.

The Challenges of Extruder Recycling

While extruder recycling holds numerous benefits, it also poses various challenges that must be addressed for a successful program implementation. One of the key challenges is the presence of contaminants in the plastic waste. Contaminants such as dirt, labels, adhesives, and other non-plastic materials can interfere with the recycling process and affect the quality of the end product. Proper sorting and pre-processing techniques are essential to remove these contaminants and ensure a high-quality recycled material.

Another challenge lies in the diversity of plastic materials. Different types of plastics require different processing techniques, temperatures, and conditions. Without proper knowledge and understanding of these variations, it can be challenging to achieve optimal recycling results. Additionally, the lack of standardized recycling symbols and labeling on plastic products further complicates the sorting and identification process, making it harder to determine the appropriate recycling method for each material.

Implementing an Effective Extruder Recycling Program

To overcome the challenges and maximize the benefits of extruder recycling, it is crucial to implement an effective recycling program. Here are some best practices for establishing a successful extruder recycling program:

1. Education and Training

Educating employees and stakeholders about the importance of extruder recycling and providing them with training on proper recycling practices is essential. This will ensure that everyone is aware of the program's goals, understands the recycling processes, and knows how to sort and handle plastic waste correctly. Regular training sessions and informative materials can help reinforce these practices and foster a recycling-oriented culture within the organization.

2. Advanced Sorting Techniques

Utilizing advanced sorting techniques is crucial to achieving high-quality recycling results. Automated sorting systems equipped with sensors and optical scanners can efficiently identify and separate different types of plastics based on their chemical composition, color, and structure. These systems help eliminate manual sorting errors and increase the accuracy of the recycling process. Additionally, incorporating manual inspections and quality control checks can further ensure that only clean and uncontaminated materials are processed.

3. Proper Pre-processing and Cleaning

Before the plastic waste can be successfully extruded and recycled, proper pre-processing and cleaning are necessary. This involves shredding or granulating the plastic into smaller pieces to facilitate the extrusion process. Additionally, thorough cleaning is essential to remove any contaminants that could affect the quality of the final product. Depending on the type of plastic, different pre-processing techniques such as washing, grinding, or heating may be required to ensure optimal results.

4. Collaborating with Recycling Facilities

Establishing partnerships with recycling facilities is crucial for the success of an extruder recycling program. Working closely with these facilities allows for the exchange of knowledge, expertise, and best practices. Recycling facilities can provide valuable insights into the specific requirements and limitations of the recycling process, ensuring that the recycled plastic meets the necessary quality standards. Additionally, collaborating with recycling facilities can help ensure a consistent supply and demand cycle for recycled materials.

5. Monitoring and Evaluation

Continuous monitoring and evaluation of the extruder recycling program is vital to identify areas for improvement and ensure its ongoing success. Regularly assessing the program's performance, tracking key performance indicators, and analyzing the data will help identify inefficiencies and enable the implementation of corrective measures. Monitoring can include evaluating the quality of the recycled material, tracking recycling rates, and identifying trends and patterns in the generation and disposal of plastic waste.

Summary

Extruder recycling is a crucial component of a successful recycling program. By implementing the best practices discussed in this article, companies can effectively minimize plastic waste, conserve resources, and reduce their environmental footprint. Education and training, advanced sorting techniques, proper pre-processing and cleaning, collaboration with recycling facilities, and monitoring and evaluation are key elements in establishing an efficient and sustainable extruder recycling program.

While challenges such as contaminants and diverse plastic materials exist, they can be overcome with the right strategies and technologies. By prioritizing extruder recycling, companies contribute to the circular economy and promote sustainable practices that benefit both the environment and their bottom line. It is essential for organizations to recognize the importance of extruder recycling and take proactive steps towards implementing and improving their recycling programs. Together, we can make a significant impact in reducing plastic waste and building a greener future.

Building a brand as TENGDA from the very start is simple so long as you keep 'the three C's' in mind: clarity, consistency and constancy.

Nanjing Tengda Machinery Co., Ltd.’s purpose is to create superior value for our customers, employees, communities and investors through the production, conversion, delivery and sale of energy and energy services.

TENGDA clearly and succinctly expresses what our company is all about. Strong brands cut through the noise to grab the audience and immediately shed light on the character of the product or service.

To properly understand what customers want, when, why and how they want it, Nanjing Tengda Machinery Co., Ltd. needs to pivot toward sentiment analysis, a burgeoning technology that taps into consumer demand based on natural language processing.