Extruder Recycling: The Role of Extruders in the Circular Economy

Introduction:

In today's world, the significance of recycling and incorporating sustainable practices has become increasingly prominent. Industries across various sectors are actively seeking ways to reduce their environmental impact and move towards a circular economy. One such technology that is contributing significantly to this cause is extruder recycling. With its ability to process and transform plastic waste into reusable materials, extruders are playing a pivotal role in promoting a sustainable and circular economy. This article dives deep into understanding the role of extruders in the circular economy and explores the various benefits they offer in terms of waste reduction, resource conservation, and economic growth.

The Basics of Extruder Recycling

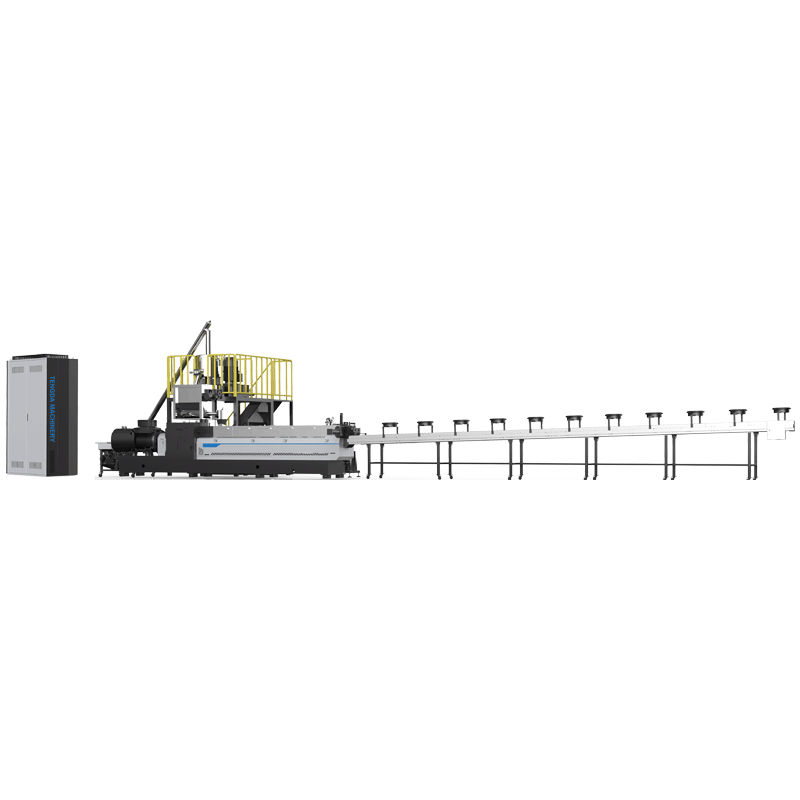

Extruder recycling involves the use of extruders, which are machines designed to melt and reshape plastic materials. These machines are capable of processing a wide range of plastic waste, transforming it into new products or materials. The process begins with the collection of plastic waste, which is then cleaned, shredded, and fed into the extruder. The extruder heats the resin until it reaches a molten state, allowing it to be extruded through a die into the desired shape and form. The resulting product can be used in a variety of applications, reducing the need for virgin plastic production.

The Environmental Benefits of Extruder Recycling

Extruder recycling offers several environmental benefits that contribute to the transition towards a circular economy. Firstly, it helps prevent plastic waste from ending up in landfills or polluting oceans and natural habitats. By reusing and recycling plastic materials, extruders significantly reduce the amount of waste generated and promote a more sustainable approach to plastic consumption. Additionally, recycling plastic through extruders helps conserve natural resources that are otherwise used to produce virgin plastic. This reduction in resource extraction and energy consumption contributes to the conservation of valuable raw materials and reduces greenhouse gas emissions associated with plastic production.

Moreover, extruder recycling plays a crucial role in tackling the issue of microplastics. Microplastics, tiny particles of plastic that pollute the environment, have become a major concern due to their adverse effects on ecosystems and human health. By recycling plastic waste through extruders, the production of new plastic is minimized, thereby reducing the release of microplastics into the environment. This helps combat the spread of microplastics and their potential long-term consequences.

Economic Opportunities and Job Creation

Extruder recycling not only benefits the environment but also presents significant economic opportunities. The circular economy approach promotes a shift from the linear 'take-make-dispose' model to a system that emphasizes resource efficiency and sustainability. By adopting extruder recycling techniques, businesses can establish new revenue streams and tap into the growing demand for recycled plastic materials. Furthermore, recycling processes create job opportunities in the collection, sorting, and processing of plastic waste, contributing to local economies and social development.

In addition to generating economic value, extruder recycling also helps businesses save costs. Utilizing recycled plastic materials can be more cost-effective compared to virgin plastics, especially for industries that require large quantities of plastic in their manufacturing processes. Additionally, by reducing the need for landfill space and lowering waste management costs, extruder recycling can lead to significant savings for municipalities and waste management organizations.

Technological Advancements and Innovation

As the demand for sustainable practices continues to grow, advancements in extruder recycling technology are being made to enhance efficiency and broaden the range of materials that can be processed. Innovations in extruder design, such as twin-screw extruders, offer improved processing capabilities, enabling the recycling of a wider variety of plastics, including more complex and composite materials. Furthermore, the development of advanced monitoring and control systems allows for precise control over the extrusion process, resulting in higher quality and consistency of recycled materials.

Another area of technological advancement is the incorporation of additive manufacturing, also known as 3D printing, with recycled plastic materials. By using recycled plastics as feedstock, 3D printing can contribute to a more sustainable manufacturing process, reducing waste and energy consumption. This combination of extruder recycling and additive manufacturing presents exciting possibilities for the creation of customized, environmentally friendly products.

Conclusion

Extruder recycling plays a vital role in building a circular economy by transforming plastic waste into valuable materials. It offers significant environmental benefits, including waste reduction, resource conservation, and the prevention of microplastic pollution. Furthermore, extruder recycling presents economic opportunities, stimulates job creation, and fosters technological advancements that drive sustainable innovation. By embracing extruder recycling and promoting its adoption across industries, we can move closer to a future where waste is minimized, resources are conserved, and the circular economy thrives. Together, we can pave the way for a greener and more sustainable world.

Nanjing Tengda Machinery Co., Ltd. is willing to push up our sleeves and wade into unknown territory with equal parts fearlessness and optimism.

Nanjing Tengda Machinery Co., Ltd.’s mission is to provide high quality care and services to our members and to be profitable in the process.

We persevere in keeping the customers pleasant and supporting them with Application at a reasonable price.

We should take a step back to review how TENGDA approach tracking, implementing, and communicating compliance-related changes and attempt to identify areas of improvement in their processes.

While extruder machine manufacturers, plastic extruder machine manufacturers Application can help achieve high accuracy._x000D_