Innovating Sustainability: Plastic Recycling Extruder Machines for Eco-Conscious Production

Introduction:

In today's world, where environmental concerns are at an all-time high, sustainability has become a critical focus for many industries. Plastic waste, in particular, poses a significant threat to our planet. To combat this issue, innovative solutions have emerged, one of them being plastic recycling extruder machines. These state-of-the-art devices have revolutionized the recycling process, providing a sustainable and eco-conscious approach to production. In this article, we will delve into the world of plastic recycling extruder machines, exploring their functionality, benefits, and their crucial role in shaping a more sustainable future.

The Importance of Plastic Recycling

Plastic recycling has garnered immense attention in recent years, and for good reason. The production and disposal of plastic products contribute greatly to pollution and environmental degradation. Traditional methods of waste management, such as landfilling or incineration, fall short in addressing the magnitude and complexity of the plastic waste issue. Recycling, on the other hand, offers a sustainable alternative that not only reduces the environmental impact of plastic waste but also conserves valuable resources.

The Role of Extrusion in Plastic Recycling

Extrusion is a widely utilized process in the plastic industry. Its principle involves melting plastic materials and shaping them into different forms. In the context of recycling, extrusion plays a crucial role in converting post-consumer or post-industrial plastic waste into reusable materials. Plastic recycling extruder machines facilitate this process by applying heat and pressure to melt and filter the plastic, transforming it into pellets or other usable forms.

The Functionality of Plastic Recycling Extruder Machines

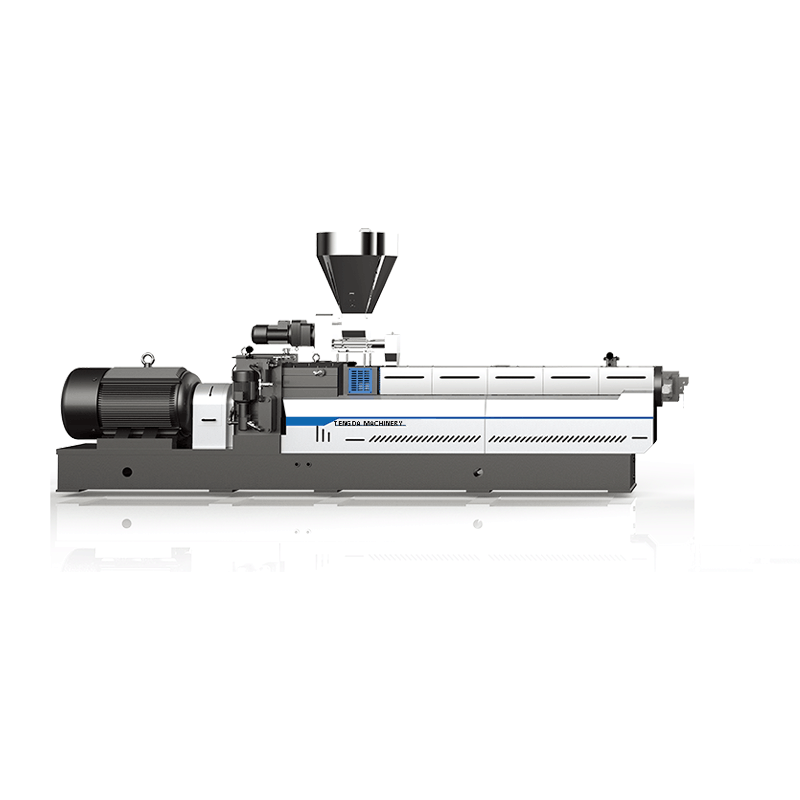

Plastic recycling extruder machines are sophisticated pieces of equipment specifically designed to handle the complexities of recycling plastic waste. These machines consist of various components that work in synergy to achieve efficient and high-quality recycling.

1. Metal and Plastic Sorting Systems

At the beginning of the recycling process, plastic recycling extruder machines employ advanced sorting systems to separate plastic waste from other materials. This automated system uses sensors and optical technology to identify different types of plastics, ensuring accurate sorting and reducing contamination. Through this preliminary step, the quality and integrity of the recycled material are significantly enhanced.

2. Shredding or Grinding Mechanism

Plastic waste is typically in the form of various shapes and sizes, ranging from bottles to packaging materials. To facilitate the recycling process, plastic recycling extruder machines incorporate shredding or grinding mechanisms. These mechanisms break down the plastic waste into smaller, more uniform pieces, increasing the efficiency of subsequent processes.

3. Melting and Filtration

Once the plastic waste has been processed into smaller pieces, it undergoes the melting and filtration stage. In this step, the shredded plastic is heated to its melting point and transformed into a molten state. The molten plastic is then passed through a filtration system, removing any impurities or contaminants that may have been present in the original waste. This ensures that the resulting recycled material meets the required quality standards.

4. Forming and Cooling

After the filtration process, the molten plastic is shaped into the desired form using various techniques such as injection molding or extrusion. Plastic recycling extruder machines can extrude the molten plastic into pellets, which are widely used in manufacturing new plastic products. Once the desired form is achieved, the recycled plastic undergoes a cooling process, solidifying it into its new shape.

5. Quality Control and Monitoring

To ensure the integrity and quality of the recycled material, plastic recycling extruder machines are equipped with advanced quality control and monitoring systems. These systems continuously analyze key parameters such as temperature, pressure, and composition, allowing for real-time adjustments to optimize the recycling process. This level of control ensures that the final recycled plastic meets the required specifications and can be seamlessly incorporated into the production of new products.

The Benefits of Plastic Recycling Extruder Machines

Plastic recycling extruder machines offer numerous benefits that contribute to sustainable production and eco-conscious practices. Here are some notable advantages:

1. Waste Reduction and Resource Conservation

By recycling plastic waste, extruder machines significantly reduce the amount of plastic ending up in landfills or oceans. This waste reduction not only helps alleviate environmental pollution but also conserves valuable resources that would otherwise be expended in the production of virgin plastic.

2. Energy Efficiency and Emissions Reduction

Compared to the production of virgin plastic, recycling plastic requires considerably less energy. Plastic recycling extruder machines optimize the recycling process, minimizing energy consumption and decreasing greenhouse gas emissions. This energy efficiency contributes to a lower carbon footprint and a more sustainable industrial landscape.

3. Promotion of Circular Economy

Plastic recycling extruder machines play a vital role in promoting a circular economy by facilitating the transition from a linear 'take-make-dispose' model to one that focuses on recycling and reusing materials. Through the use of these machines, plastic waste is transformed into valuable resources that can be utilized in the production process, reducing the dependence on virgin materials.

4. Closing the Plastics Loop

Plastic recycling extruder machines enable the closed-loop recycling of plastic, meaning that recycled plastic can be used to produce new products without compromising their quality or performance. This closed-loop system minimizes waste generation and extends the lifespan of plastic materials, ultimately reducing the demand for virgin plastics.

Conclusion

Plastic recycling extruder machines offer a game-changing solution in the quest for a more sustainable and eco-conscious future. By employing advanced technology and efficient processes, these machines enable the transformation of plastic waste into valuable resources. With their ability to reduce waste, conserve resources, and promote a circular economy, plastic recycling extruder machines are an innovative step towards mitigating the environmental impact of plastic production. It is crucial for industries and governments to invest in such technologies and embrace sustainable practices to address the plastic waste crisis effectively. Through collaborative efforts, we can revolutionize production processes and pave the way for a greener and more sustainable planet.

Nanjing Tengda Machinery Co., Ltd. have now make a decision to enlarge our company in other countries.

You can get a of any specification from Nanjing Tengda Machinery Co., Ltd. as we have varied specifications to suit different plastic extruder machine manufacturers needs and cater to a wide client base existing in both domestic and overseas market. please feel free to enquire us at TENGDA Extruder Machine Manufacturers.

Nanjing Tengda Machinery Co., Ltd. has a number of producing line for producing Application.