Key Considerations When Choosing a Sheet Extruder for Your Plastic Manufacturing Business

Key Considerations When Choosing a Sheet Extruder for Your Plastic Manufacturing Business

Introduction

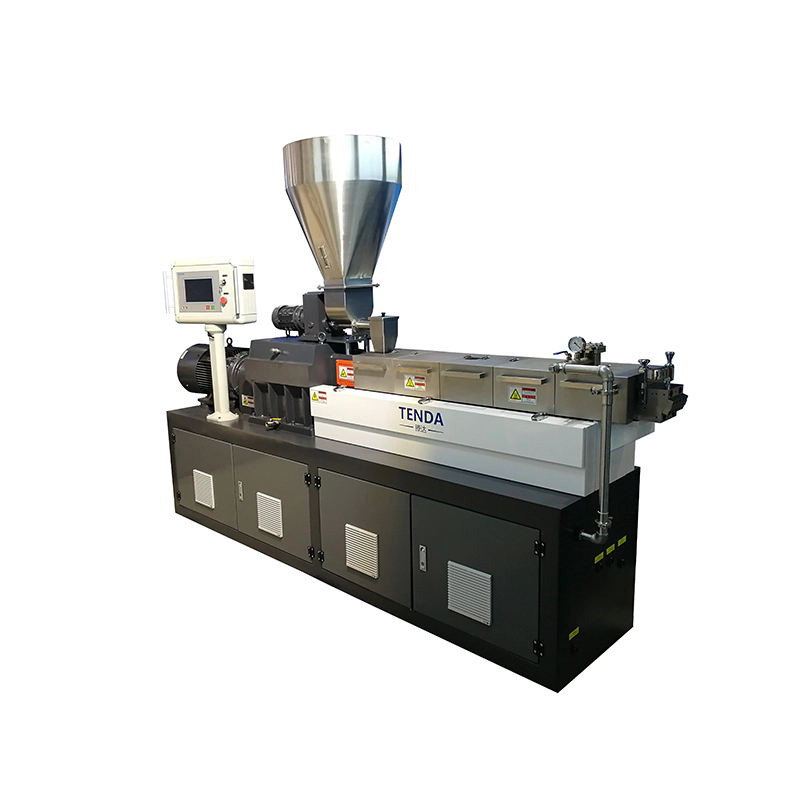

In the plastic manufacturing industry, investing in the right equipment is crucial for the success of your business. One such essential equipment is a sheet extruder, which is used to produce plastic sheets of various types and sizes. Choosing the right sheet extruder requires careful consideration of several factors to ensure optimal performance, quality output, and cost-effectiveness. This article discusses the key considerations you should keep in mind when selecting a sheet extruder for your plastic manufacturing business.

1. Production Capacity and Size Flexibility

The first consideration when choosing a sheet extruder is its production capacity and size flexibility. You should assess the amount of plastic sheet output you need based on your production requirements. Additionally, consider whether you require the extruder to handle different sheet sizes or if you have specific size requirements. Determining these factors will help you determine the appropriate extruder size and capacity to meet your production demands effectively.

2. Material Compatibility

Another vital factor to consider is the extruder's compatibility with different types of plastic materials. Depending on your manufacturing needs, you may work with various plastic resins like polypropylene, polyethylene, polystyrene, PVC, or PET. Ensure that the sheet extruder you choose can handle the specific materials you work with. It should be capable of melting and shaping these plastic resins without compromising the quality of the final product.

3. Control Systems and Automation

Efficient and user-friendly control systems are essential for smooth operations and minimizing errors. Modern sheet extruders come equipped with advanced automation technologies, offering precise control over various parameters such as temperature, speed, thickness, and cooling. These control systems ensure consistent quality and reproducibility of plastic sheets. When choosing a sheet extruder, opt for a machine with user-friendly controls to facilitate ease of operation and reduce the risk of human error.

4. Energy Efficiency

Energy consumption is a significant contributor to the operational cost of a sheet extruder. Therefore, it is essential to select an extruder that is energy-efficient without compromising performance. Look for features like efficient heating elements, well-insulated barrels, and energy-saving motor systems. These features can significantly reduce energy consumption, making your plastic manufacturing process more sustainable and cost-effective in the long run.

5. Maintenance and Service Support

Regular maintenance is crucial for keeping your sheet extruder in optimal condition and preventing breakdowns. Look for extruders that are designed for easy maintenance. Consider the availability of spare parts and the reputation of the manufacturer or supplier for providing excellent after-sales service. Adequate service support ensures timely repairs and minimizes downtime, thus maximizing your operational efficiency.

6. Cost and Return on Investment

While the initial cost of purchasing a sheet extruder is an important consideration, you should also evaluate the long-term return on investment (ROI). Consider the overall cost-effectiveness of the extruder, including factors such as energy efficiency, maintenance requirements, and projected productivity. A higher-priced extruder with better efficiency and longevity could potentially offer a higher ROI in the long term compared to a cheaper model with frequent breakdowns and higher energy consumption.

Conclusion

Choosing the right sheet extruder is critical for the success and profitability of your plastic manufacturing business. Considering factors such as production capacity, material compatibility, control systems, energy efficiency, maintenance, and ROI will help you make an informed decision. Take your time to thoroughly research and compare different models and consult with experts in the industry before finalizing your purchase. Investing in a quality sheet extruder will ensure consistent production of high-quality plastic sheets, reduce costs, and enhance overall operational efficiency.