Leading Technology Supplier for Advanced Plastic Compounding Machines and Extruders

*Introduction: The Dawn of Advanced Plastic Compounding Machines and Extruders*

In the ever-evolving landscape of manufacturing and materials engineering, plastic compounding machines and extruders play an integral role. These sophisticated machines transform raw polymer materials into finished products that fuel countless industries. This article will dive deep into the world of advanced plastic compounding machines and extruders, offering insights into their technology, applications, and the companies leading the charge in this dynamic field.

With a keen focus on innovation, quality, and efficiency, the suppliers of these advanced machines are pivotal in driving technological progress and industry growth. By understanding the intricacies and importance of these technologies, businesses can enhance their production processes, bringing superior products to market at a faster rate.

*The Technology Behind Advanced Plastic Compounding Machines and Extruders*

To truly appreciate the value that advanced plastic compounding machines and extruders bring to modern manufacturing, one must first understand the technology that underpins them. At their core, these machines are designed to blend various polymers with additives to create compounds that exhibit specific properties. This technological process ensures that the final product meets rigid standards for quality, durability, and functionality.

Advanced plastic compounding machines employ sophisticated techniques such as twin-screw extrusion, which ensures meticulous mixing and processing of materials. Twin-screw extruders, characterized by their two intermeshing screws, facilitate thorough blending and ensure uniform dispersion of additives. This results in compounds with consistent quality and performance characteristics, making them ideal for high-precision applications.

The integration of cutting-edge sensors and automation within these machines allows for real-time monitoring and control of the compounding process. This not only enhances efficiency but also ensures precise control over the quality of the end product. Advanced software interfaces provide operators with critical data and feedback, allowing for quick adjustments and optimizing production runs.

Furthermore, advances in material science have enabled the development of compounding machines that can handle a diverse array of polymers, including thermoplastics, elastomers, and biopolymers. This versatility opens up new avenues for creating innovative materials that meet the ever-changing demands of various industries, from automotive to electronics and beyond.

*Applications and Industries Benefiting from Advanced Compounding Machines*

The impact of advanced plastic compounding machines and extruders transcends multiple industries, each reaping the benefits of optimized material properties and enhanced manufacturing processes. One of the most notable applications is in the automotive industry, where lightweight yet durable plastic compounds are paramount for producing fuel-efficient vehicles.

In the construction industry, these machines enable the production of weather-resistant and sturdy materials that are essential for modern infrastructure projects. Pipes, fittings, and insulation materials made from advanced plastic compounds offer enhanced performance, durability, and longevity, all of which are critical in construction applications.

The electronics industry also heavily relies on the precision and quality assured by advanced compounding machines. From cables and connectors to housings and components, the electronics sector demands materials that provide exceptional electrical insulation, thermal resistance, and mechanical strength. Advanced plastic compounds meet these requirements, ensuring the reliability and safety of electronic devices.

Furthermore, in the medical field, the importance of these machines cannot be overstated. Medical devices and equipment made from specialized plastic compounds exhibit biocompatibility, sterilizability, and durability. Everything from surgical instruments to prosthetics benefits from the superior material properties achieved through advanced plastic compounding.

The packaging industry, with its focus on sustainability and innovation, also finds immense value in these machines. Advanced compounding enables the creation of biodegradable and eco-friendly packaging materials. These sustainable alternatives align with environmental goals and meet the growing consumer demand for green products.

*Leading Suppliers in the Market*

The advancement of plastic compounding machines and extruders is driven by a select group of pioneering companies that continually push the boundaries of technology and innovation. These industry leaders are dedicated to providing high-quality, reliable, and efficient machines that cater to the ever-evolving needs of their clients.

One such reputable supplier is Coperion, a global leader renowned for its expertise in compounding and extrusion technologies. With decades of experience, Coperion offers a range of advanced twin-screw extruders and complete compounding systems that set industry standards. Their innovative solutions are tailored to enhance productivity, reduce energy consumption, and deliver unparalleled compound quality.

Leistritz Extrusion, another prominent name in the field, specializes in customized compounding and extrusion solutions. Known for their engineering prowess and commitment to excellence, Leistritz provides machines that excel in handling a wide range of materials and applications. Their focus on continuous improvement and customer-centric approaches ensures that their clients receive cutting-edge technology and support.

Prominent in North America, Steer Engineering is celebrated for its groundbreaking innovations in materials processing. Their advanced extruders and compounding machines are designed to handle complex formulations with precision and efficiency. Steer's emphasis on research and development has positioned them as a go-to supplier for industries seeking top-tier performance and tailored solutions.

Additionally, KraussMaffei Berstorff, with its rich history and technological expertise, offers state-of-the-art compounding and extrusion systems. Their comprehensive range of machines caters to various industries, ensuring optimal performance and reliable production. KraussMaffei Berstorff's commitment to sustainability and innovation make them a prominent player in the market.

*Key Innovations and Trends in Plastic Compounding and Extrusion*

The field of plastic compounding and extrusion is continually evolving, driven by key innovations and emerging trends that shape the future of materials processing. One such trend is the increasing emphasis on sustainability and eco-friendly practices. As the world grapples with environmental challenges, the demand for biodegradable and recycled materials has surged. Advanced compounding machines are now capable of processing sustainable polymers, contributing to a circular economy and reducing plastic waste.

Another notable trend is the integration of digitalization and Industry 4.0 principles in compounding and extrusion processes. Smart factories equipped with interconnected machinery and IoT-enabled sensors allow for real-time monitoring, predictive maintenance, and seamless data exchange. This digital transformation enhances operational efficiency, minimizes downtime, and ensures optimal resource utilization.

The development of high-performance materials is another area of focus, significantly influencing the capabilities of compounding machines. Innovations in nanotechnology and advanced composites have opened new possibilities for creating materials with unprecedented properties. From enhanced strength and thermal conductivity to superior electrical insulation, these materials are revolutionizing industries and expanding application horizons.

Additionally, customization and flexibility in production are becoming paramount. Modern compounding machines are designed to accommodate a wide range of formulations, allowing manufacturers to create bespoke compounds tailored to specific needs. This flexibility not only diversifies product offerings but also empowers businesses to swiftly respond to market demands and trends.

Automation and advanced control systems are also gaining prominence in the industry. The implementation of machine learning algorithms and artificial intelligence is transforming how compounding processes are managed and optimized. Automated systems not only enhance precision but also reduce human intervention, mitigating the risk of errors and increasing overall productivity.

*Challenges and Solutions in the Industry*

While the advancements in plastic compounding machines and extruders are undoubtedly impressive, the industry faces its share of challenges. One significant challenge is the continuous need for innovation to keep up with evolving market demands. Manufacturers must invest in research and development to stay ahead of the curve and address the ever-changing requirements of their clients.

Another challenge is the complexity of processing advanced materials. As new polymers and additives are developed, ensuring compatibility and achieving consistent quality can be demanding. Advanced compounding machines need to be highly adaptable and capable of handling a diverse range of formulations. Collaborative efforts between material scientists and machine manufacturers are crucial to overcoming these challenges.

Energy consumption and sustainability remain critical concerns. While advanced machines are becoming more energy-efficient, there is an ongoing push to minimize the environmental impact of manufacturing processes. Companies are increasingly focusing on incorporating renewable energy sources and optimizing machine designs to reduce energy usage without compromising performance.

Regulatory compliance and quality assurance are also paramount in the industry. Strict regulations govern the production of plastic compounds, especially in sectors such as medical and food packaging. Ensuring that machines meet these standards and allow for traceability and quality control poses a significant challenge for manufacturers and suppliers.

Finally, the industry grapples with the need for skilled labor. Operating and maintaining advanced compounding machines require specialized knowledge and expertise. Training and upskilling of the workforce are essential to ensure that operators can effectively manage sophisticated machinery and maximize its potential.

*Conclusion*

In conclusion, the realm of advanced plastic compounding machines and extruders is marked by remarkable technological progress and innovation. These machines, equipped with cutting-edge technology and advanced capabilities, play a vital role in shaping numerous industries. From the automotive and construction sectors to electronics and medical fields, the impact of high-performance plastic compounds is far-reaching.

Leading suppliers like Coperion, Leistritz Extrusion, Steer Engineering, and KraussMaffei Berstorff are at the forefront of this technological revolution, driving efficiency, quality, and sustainability in material processing. Their commitment to innovation and excellence propels the industry forward, meeting the demands of a dynamic market.

As the industry continues to evolve, key trends such as sustainability, digitalization, and customization will define the future of plastic compounding and extrusion. Overcoming challenges and capitalizing on emerging opportunities will be essential for continued growth and advancement. By embracing these changes and leveraging cutting-edge technology, manufacturers can optimize their processes, achieve superior product quality, and contribute to a more sustainable and innovative future.

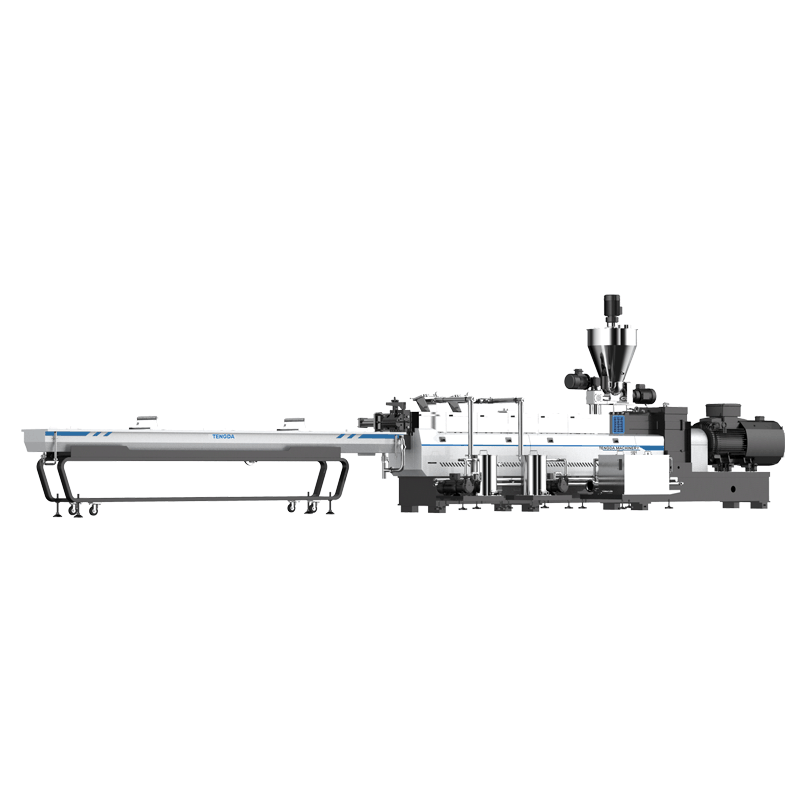

TENGDA allocates customer service resources to the platform where their customers are most vocal.

Nanjing Tengda Machinery Co., Ltd. attaches great importance to customers and assists them in achieving their demands.

We take advantage of high technology to produce products that support safer and better quality and that enhance the using experience of Application.