Plastic Recycling Extruder: The Challenges and Opportunities of Recycling Plastic

The Challenges and Opportunities of Recycling Plastic

Introduction:

Plastic waste has become a global environmental crisis, with millions of tons ending up in landfills and oceans each year. As the urgency to address this issue grows, companies and individuals are looking for innovative solutions to tackle the challenge. One promising technology that has gained significant attention is the plastic recycling extruder. This article explores the challenges associated with plastic recycling and the opportunities that arise with the use of extruders in the process.

The Environmental Impact of Plastic Waste

Plastic waste has become a significant threat to our planet and its inhabitants. It poses severe risks to wildlife, marine ecosystems, and human health. Plastic pollution affects various species through ingestion, entanglement, and habitat destruction. Additionally, microplastics, resulting from the breakdown of larger plastic items, contaminate our food chain, and ultimately find their way back into our bodies. It is clear that urgent action is required to address this crisis.

The Challenges of Plastic Recycling

Although plastic recycling is touted as a solution to mitigate the environmental impact of plastic waste, it faces several challenges. The first hurdle lies in the complexity of plastic itself. Plastics come in countless variations, each with its unique chemical composition, melting point, and properties. Sorting and separating different types of plastic is a laborious and time-consuming process. Furthermore, contaminants such as food residues, labels, and adhesives often remain attached to the plastic items, further complicating the recycling process.

Another challenge is the lack of infrastructure for plastic recycling. In many regions, recycling facilities are scarce, making it difficult for individuals and businesses to participate in effective recycling systems. This results in a higher percentage of plastic waste being sent to landfills or incinerated, exacerbating the environmental impact.

Additionally, the cost of recycling plastic is often higher than producing new plastic from virgin materials. This economic barrier discourages investment in recycling technologies and inhibits its widespread adoption. Moreover, the outdated perception of recycled plastic as inferior quality creates a demand-supply gap, affecting the market viability of recycled plastic products.

The Role of Plastic Recycling Extruders

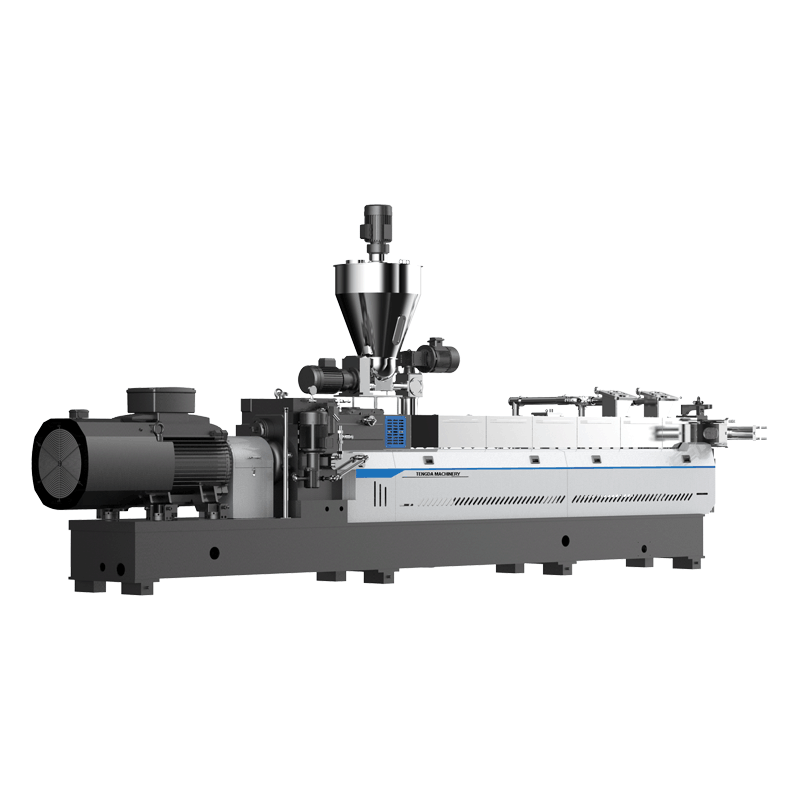

Plastic recycling extruders have emerged as a promising technology to address the challenges associated with plastic recycling. These machines are designed to melt and reshape plastic waste into reusable raw materials. Extruders can handle various types of plastics, including polyethylene terephthalate (PET), high-density polyethylene (HDPE), and polypropylene (PP), among others.

One key advantage of extruders is their ability to process mixed plastic waste. By melting and forming plastic at high temperatures, extruders can effectively separate different types of plastics, allowing for a more streamlined recycling process. The output can be in the form of plastic pellets or even shaped into new products, depending on the desired application.

Furthermore, extruders can help reduce the cost of recycling plastic. By transforming plastic waste into raw materials, extruders provide a valuable commodity that can be used in various industries. This not only diverts plastic waste from landfills but also reduces the dependency on virgin plastic production, leading to significant cost savings in the long run.

The Opportunities and Innovations

The use of plastic recycling extruders opens up numerous opportunities and encourages innovation in the recycling industry. It enables the creation of a circular economy where plastic products can be continuously recycled and reused without compromising quality. This shift towards a closed-loop system has the potential to reduce the reliance on fossil fuels, lower greenhouse gas emissions, and mitigate the environmental impact of plastic waste.

Furthermore, the development of advanced extruder technologies provides an avenue for the creation of high-value products from recycled plastic. For instance, companies are exploring the use of 3D printing filaments made from recycled plastic, contributing to the growing demand for sustainable manufacturing practices. From furniture to packaging materials, the possibilities of using recycled plastic are endless.

Innovations in extruder technology are also contributing to improved efficiency and reduced energy consumption. Advanced extruder designs incorporate features such as heat recovery systems and energy-efficient motors, making the recycling process more sustainable. These developments not only benefit the environment but also help reduce operational costs for recycling facilities.

Conclusion

Plastic recycling extruders offer a ray of hope in the battle against plastic waste. They provide a practical solution to the challenges faced in plastic recycling, offering a more efficient and cost-effective method to transform plastic waste into valuable resources. By embracing this technology and investing in the necessary infrastructure, we can make significant strides in reducing our plastic footprint and moving towards a more sustainable future. As individuals, businesses, and governments, it is crucial to recognize the opportunities and encourage the adoption of plastic recycling extruders to protect our planet for generations to come. We must act now to reshape the future of plastic recycling and pave the way for a cleaner and greener world.

These Application extruder machine manufacturers are meant to serve as a guide for business owners on how to both identify potential opportunities for transformative innovation and how to adapt to the constantly changing technologies of today.

The 21st century is sure to bring more innovation, new services and newer technology, thus new products and services to sell. Nanjing Tengda Machinery Co., Ltd. will continue to shape and lead the markets in which it chooses to compete.

For optimal plastic extruder machine manufacturers, choose a high-quality Application system and make sure a certified installer sets it up.