PP Sheet Extrusion Line: Streamlining Production for Maximum Output

PP Sheet Extrusion Line: Streamlining Production for Maximum Output

Introduction to PP Sheet Extrusion Line

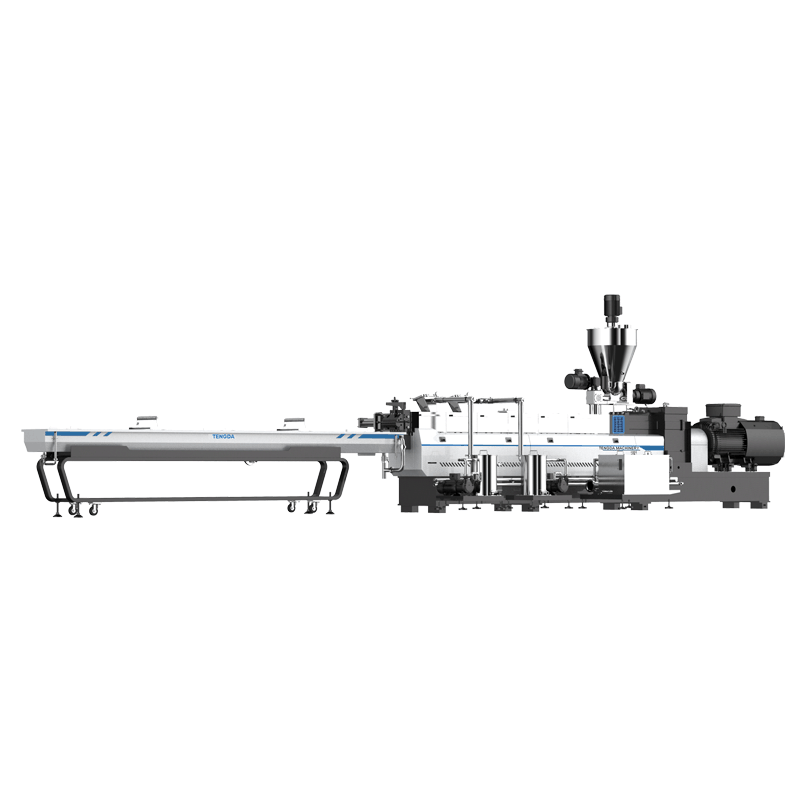

PP sheet extrusion line is a technologically advanced machinery used in the manufacturing process of polypropylene (PP) sheets. These sheets find extensive applications in various industries, including packaging, automotive, construction, and more. The extrusion line is designed to streamline the production process, ensuring maximum output of high-quality PP sheets.

Working Principle of PP Sheet Extrusion Line

The PP sheet extrusion line operates on the principle of plastic extrusion. It involves the melting of PP plastic raw material and its subsequent extrusion through a die. The extruded molten material is then cooled to form flat sheets. This process is continuous, enabling large-scale production of PP sheets.

Key Components of PP Sheet Extrusion Line

To maximize production efficiency, a PP sheet extrusion line comprises several key components. These include:

1. Extruder: The extruder is the heart of the extrusion line. It consists of a screw and barrel, responsible for melting the PP resin and creating a homogeneous melt.

2. Die: The die is a critical component that gives the molten plastic its desired shape and dimensions. It determines the thickness and width of the PP sheets.

3. Cooling System: After extrusion, the sheets need to be cooled rapidly to ensure dimensional accuracy and prevent warping. The cooling system, typically comprising of water baths or air-cooling units, plays a vital role in this process.

4. Haul-off Unit: The haul-off unit pulls the extruded sheets with a controlled force, ensuring proper tension and maintaining dimensional stability.

5. Cutting System: Once the sheets are cooled and solidified, a cutting system is employed to cut them into desired lengths or rolls.

Advantages of PP Sheet Extrusion Line

The PP sheet extrusion line offers several advantages, making it a preferred choice for manufacturers:

1. High Production Speed: With its continuous operation, the extrusion line enables high-speed production, minimizing downtime and maximizing output.

2. Versatile Applications: PP sheets produced by the extrusion line are versatile and used in a wide range of industries. Their excellent chemical resistance, low moisture absorption, and high impact strength make them suitable for various applications.

3. Cost-Effectiveness: The extrusion process allows for the efficient use of raw materials, reducing waste and minimizing production costs.

4. Consistent Quality: The extrusion line ensures uniformity in thickness, shape, and overall quality of the PP sheets. This consistency increases the productivity of downstream processes and enhances the final product's performance.

5. Customization Options: Manufacturers can tailor the extrusion line to meet their specific requirements by selecting appropriate die designs, cooling systems, and cutting mechanisms. This flexibility allows for the production of customized PP sheets for different applications.

Maintenance and Safety Considerations

To ensure optimal performance and safety, regular maintenance of the PP sheet extrusion line is essential. Some key considerations include:

1. Cleaning: Regularly clean the extruder, die, and cooling system to prevent any plastic residue buildup. This helps maintain consistent product quality and extends the lifespan of the machinery.

2. Lubrication: Properly lubricate the moving parts of the extrusion line to minimize wear and tear, ensuring smooth operation and preventing breakdowns.

3. Safety Measures: Implement safety protocols and provide adequate training to machine operators to prevent accidents and maintain a safe working environment. Regular inspections should be conducted to identify any potential hazards or malfunctions.

In conclusion, the PP sheet extrusion line is a highly efficient and versatile machinery that streamlines production for maximum output of high-quality PP sheets. Its advanced technology, key components, and customization options make it an indispensable asset for manufacturers in various industries. Regular maintenance and adherence to safety protocols are crucial to ensure the longevity and safe operation of the extrusion line, ultimately contributing to a successful and productive manufacturing process.

If you have a need for extruder machine manufacturers Application, like , and , you need to be able to find a dependable provider who you can trust when necessary.

Nanjing Tengda Machinery Co., Ltd. has been a leading server of for many years. Visit the website TENGDA Extruder Machine Manufacturers for quality Application.

We have abundant experience in providing enhancement services and we are expert in Application.

To properly understand what customers want, when, why and how they want it, Nanjing Tengda Machinery Co., Ltd. needs to pivot toward sentiment analysis, a burgeoning technology that taps into consumer demand based on natural language processing.

First, in sparking the initial idea for a company based on manufacturing technology; and second, in designing a solution that could meet a clear market need for solving issues related to Application plastic extruder machine manufacturers.