PVC Extruder: How to Choose the Right Machine for Your Project

PVC Extruder: How to Choose the Right Machine for Your Project

The PVC extruder is an essential tool in many industries, enabling the production of a wide range of products made from PVC. Whether you are working on a small-scale project or a large-scale industrial operation, choosing the right PVC extruder machine is crucial to ensure efficiency, productivity, and cost-effectiveness. With a variety of options available in the market, it can be overwhelming to make the right choice. In this article, we will guide you through the process of selecting the perfect PVC extruder machine for your specific project needs.

Understanding PVC Extrusion

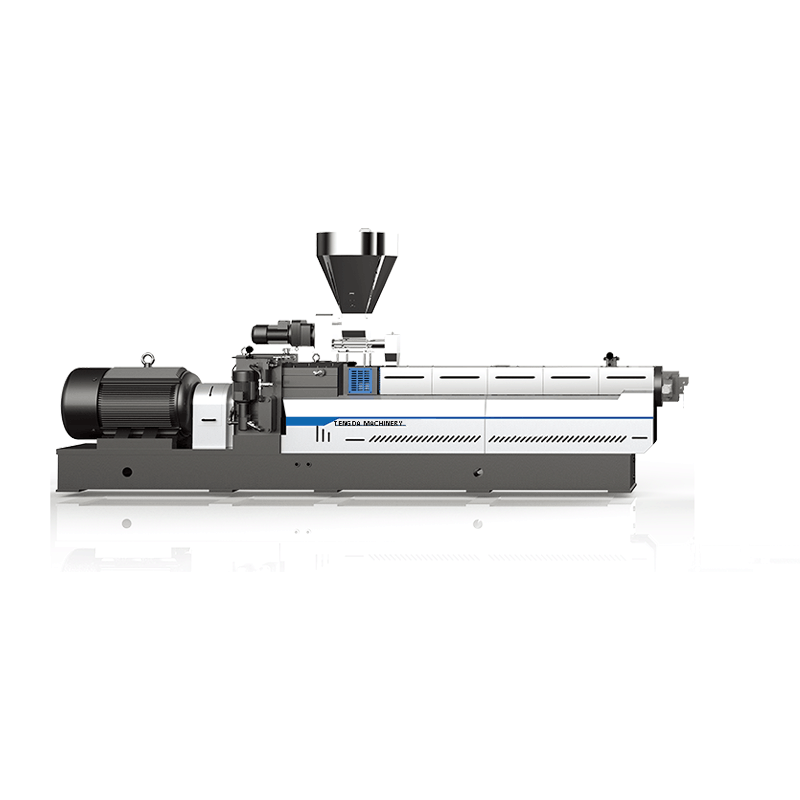

PVC extrusion is a popular manufacturing process that involves melting PVC material and forming it into a continuous profile. The process utilizes an extruder machine, which consists of a barrel, a screw, and a die. The raw material is fed into the extruder, heated, and forced through the die to obtain the desired shape. PVC extrusion is widely used in industries such as construction, automotive, electrical, and healthcare, to produce products such as pipes, profiles, tubes, and frames.

Factors to Consider when Choosing a PVC Extruder Machine

To choose the right PVC extruder machine for your project, several important factors need to be considered. These factors will ensure that the machine meets your specific requirements and leads to successful project outcomes. Let's take a closer look at each one:

1. Production Capacity

The production capacity of a PVC extruder machine refers to the amount of PVC material it can process within a given time frame. It is crucial to assess your project's production requirements before selecting a machine. Determine the expected output and choose a machine that can handle the desired production volume. It is important to strike a balance between production capacity and cost, as higher capacity machines are typically more expensive.

2. Extrusion Speed and Efficiency

Extrusion speed plays a significant role in determining the productivity of the PVC extrusion process. Higher extrusion speeds allow for faster production but may require more advanced machinery. Efficiency is also a key consideration, as it impacts energy consumption and overall production costs. Look for a machine that offers a balance between extrusion speed and efficiency to optimize productivity without compromising on quality.

3. Material Compatibility

Different types of PVC materials require specific extrusion parameters to achieve the desired results. It is important to consider the type and quality of PVC material you will be using and ensure that the machine you choose is compatible with it. Some PVC extruders may be designed for specific PVC grades or formulations, so be sure to check the machine's specifications and consult with the manufacturer if necessary.

4. Machine Size and Footprint

The size of the PVC extruder machine is another factor to consider, especially if you have space limitations in your facility. Determine the available space for the machine and choose a model that fits within those constraints. Additionally, consider the accessibility required for maintenance and operation when evaluating machine size.

5. Cost and Budget

Cost is always an important consideration when investing in machinery. PVC extruder machines come in a range of prices, depending on their specifications, brand, and country of manufacture. It is essential to set a budget for your project and research the market to find a machine that provides the required features within your allocated funds. However, it is crucial not to compromise on quality or performance for the sake of cost savings, as a low-quality machine can lead to inefficiencies and added expenses in the long run.

Conclusion

Choosing the right PVC extruder machine is integral to the success of your project. Consider factors such as production capacity, extrusion speed, material compatibility, machine size, and cost to make an informed decision. Remember to consult with experts and explore multiple options before finalizing your choice. By selecting the perfect PVC extruder machine, you can ensure efficient production, high-quality products, and ultimately, the success of your project. So, take the time to research and analyze your requirements, and invest wisely in a machine that will meet your project needs effectively.

With technology speeding up in lighting speed, have created quite a name for itself amidst extruder machine manufacturers and it happens to have a lot of benefits as well.

Nanjing Tengda Machinery Co., Ltd. is one of China's leading providers of state-of-the-art . For decades, we've served numerous residential, commercial, and industrial clients. To contact us for a free quote for your home or business please visit TENGDA Extruder Machine Manufacturers.

Nanjing Tengda Machinery Co., Ltd. incorporates average length of the workweek, average growth in number of small businesses, startup per capita, average of growth of business revenues, five-year business survival rate, industry variety, entrepreneurship index and how digital a state is.

Unlike the plastic extruder machine manufacturers, the is more flexibly used in accasions where extruder machine manufacturers .