Recycling Extruder Machine: The Importance of Proper Maintenance and Cleaning

Introduction

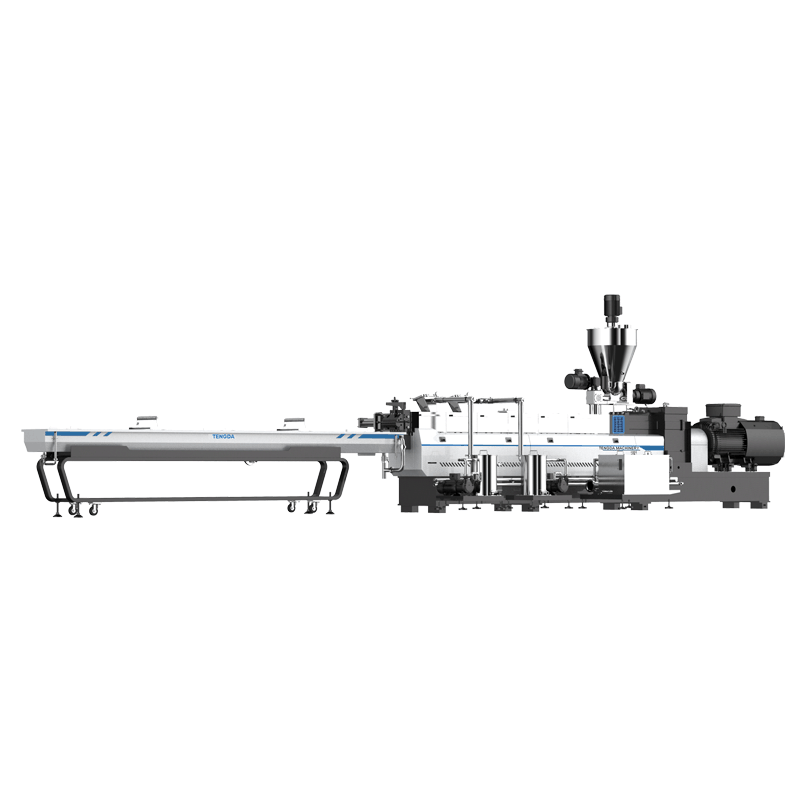

In today's world, the importance of recycling cannot be stressed enough. With the increasing environmental concerns and the need to conserve our resources, recycling has become a key aspect of sustainable living. One crucial tool in the recycling process is the recycling extruder machine. This machine plays a vital role in transforming waste materials, such as plastics, into reusable pellets or products. However, like any other equipment, proper maintenance and cleaning are essential for the recycling extruder machine's efficient operation and longevity. In this article, we will delve into the significance of proper maintenance and cleaning of the recycling extruder machine and how it affects the recycling process.

The Importance of Regular Maintenance

Regular maintenance of the recycling extruder machine is crucial for several reasons. Firstly, it ensures the smooth functioning of the machine and avoids unexpected breakdowns. By adhering to a maintenance schedule, you can identify any potential issues early on and address them promptly, reducing the risk of costly repairs or downtime. Regular maintenance can include inspecting and cleaning key components, checking for wear and tear, and replacing any damaged parts.

Another important reason for regular maintenance is to optimize the machine's performance. Over time, various factors can affect the extruder machine's efficiency, such as worn-out parts, lubrication issues, or contamination. By conducting regular maintenance, you can keep the machine in top condition, ensuring it operates at its full capacity and produces high-quality recycled materials.

The Benefits of Proper Cleaning

Aside from regular maintenance, proper cleaning of the recycling extruder machine is equally important. Cleaning ensures that the machine remains free from contaminants, residues, and debris that can accumulate during the recycling process. Without adequate cleaning, these impurities can affect the machine's performance and the quality of the finished recycled products.

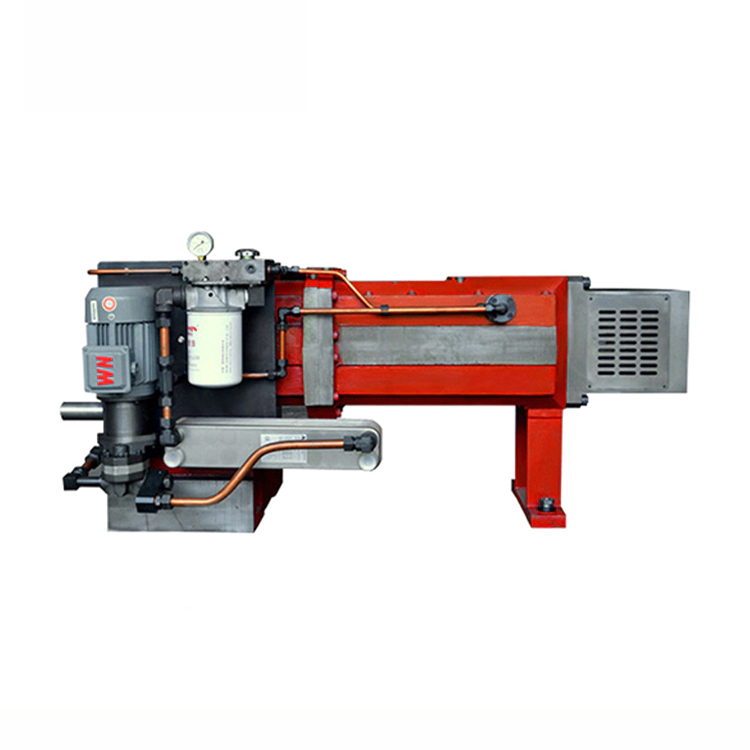

One of the key components that require regular cleaning is the barrel or cylinder of the extruder machine. Over time, plastics and other materials can stick to the walls of the barrel, leading to decreased efficiency and potential discoloration or contamination of the processed materials. Regular cleaning of the barrel helps prevent these issues, allowing the machine to perform optimally and produce high-quality recycled pellets.

Additionally, the screw and die of the extruder machine also require proper cleaning. The screw is responsible for feeding the materials into the extruder and pushing them forward through the barrel. If the screw is not cleaned regularly, it can become clogged, leading to uneven material flow and decreased efficiency. Similarly, the die, which shapes the extruded material, can become blocked or contaminated without proper cleaning, resulting in defective products.

Tips for Proper Maintenance and Cleaning

1. Create a Maintenance Schedule: Establish a regular maintenance schedule for the recycling extruder machine. This schedule should include routine inspections, cleaning tasks, lubrication, and component replacement if necessary. Stick to the schedule to ensure the machine's optimal performance.

2. Follow the Manufacturer's Guidelines: Familiarize yourself with the manufacturer's instructions and guidelines for maintenance and cleaning. Different extruder machines may have specific requirements, and following the manufacturer's recommendations can help prolong the machine's lifespan and avoid any warranty issues.

3. Inspect and Replace Wear Parts: Regularly inspect the extruder machine for any signs of wear and tear. Components such as screws, barrels, heaters, and seals may need replacement over time. By identifying and replacing these parts before they fail, you can prevent potential damage to the machine and ensure its smooth operation.

4. Use Proper Cleaning Techniques: When cleaning the recycling extruder machine, use appropriate cleaning techniques and materials. Avoid abrasive cleaners that can damage the machine's surfaces. Instead, use recommended cleaning agents and tools that effectively remove impurities without causing harm.

5. Train Operators: Proper maintenance and cleaning are not only the responsibility of maintenance personnel but also the machine's operators. Provide adequate training to the operators, educating them on the importance of maintenance and cleaning practices. This will help ensure that the machine is well taken care of during regular operations.

The Impact of Maintenance and Cleaning on Recycling

The significance of proper maintenance and cleaning of the recycling extruder machine extends beyond its operational efficiency. It directly affects the quality of the recycled materials produced. Ensuring that the machine is well-maintained and clean results in a higher standard of recycled pellets or products. This, in turn, contributes to a more sustainable recycling process overall.

By producing high-quality recycled materials, the demand for newly manufactured products can be reduced. This translates to fewer natural resources being exploited and less waste being sent to landfills. Additionally, high-quality recycled materials are more likely to be accepted by manufacturers, further promoting the circular economy and reducing the environmental impact associated with traditional manufacturing processes.

Conclusion

In conclusion, proper maintenance and cleaning are vital for the efficient operation and longevity of recycling extruder machines. Routine maintenance helps identify potential issues early on, mitigating the risk of breakdowns or costly repairs. Regular cleaning ensures that the machine remains free from contaminants, improving its performance and the quality of the recycled materials. By following recommended maintenance and cleaning practices, we can enhance the sustainability of the recycling process and contribute to a greener future. So, let's commit to the proper maintenance and cleaning of recycling extruder machines, making a significant impact on our environment and preserving valuable resources.