The Heart of Production: Understanding Pelletizing Machines

Introduction:

When it comes to manufacturing industries, pelletizing machines play a crucial role in transforming raw materials into valuable products. These versatile machines are commonly used in various sectors, including pharmaceuticals, food processing, agriculture, and plastics. Whether it is converting biomass into fuel pellets or creating uniform particles for pharmaceutical tablets, pelletizing machines are the beating heart of production processes. In this article, we will delve into the world of pelletizing machines and explore their mechanisms, applications, and benefits.

Understanding Pelletizing Machines

Pelletizing machines, also known as pelletizers, are industrial equipment designed to transform powders, granulates, or other bulk materials into small, uniform pellets. The process of pelletization involves compressing the material into small cylinders or spheres, providing several advantages over other forms of material processing. These machines offer enhanced material handling, increased product uniformity, improved storage and transport, and easier dosing.

Pelletizing machines come in various sizes and configurations, depending on the specific application and the characteristics of the materials being processed. Some pelletizers are designed to handle dry powders, while others can handle wet or sticky materials. Additionally, the capacity and speed of pelletizing machines vary, allowing manufacturers to select the most suitable one based on their production requirements.

Types of Pelletizing Machines

There are different types of pelletizing machines available, each designed to cater to specific industry needs. Let's explore some of the commonly used types:

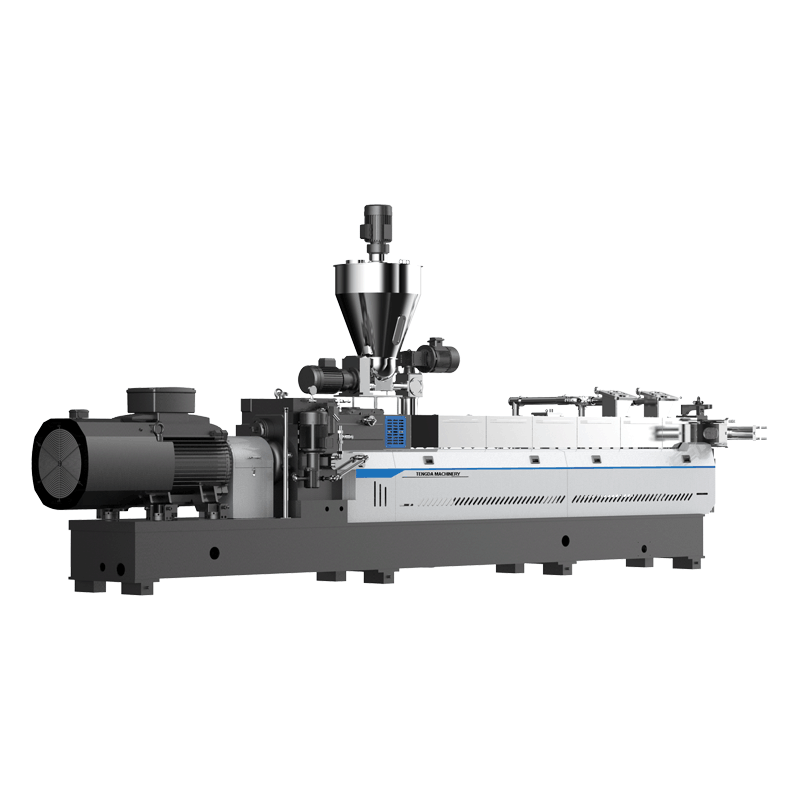

1. Extrusion Pelletizing Machines

Extrusion pelletizing machines are widely used in the plastic industry to convert plastic resin or compound into pellets. In this process, the material is melted using heat and pressure and then forced through a die, which shapes the pellets. The extrusion process ensures uniformity in pellet size, density, and shape. These machines can handle different types of plastics, including polyethylene, polypropylene, polystyrene, and PVC. Extrusion pelletizing machines offer high productivity and are essential in the production of plastic pellets for various applications.

2. Disk Pelletizing Machines

Disk pelletizing machines utilize a rotating disk to agglomerate fine materials into pellets. The process involves a rotating inclined disk that propels the material against a stationary wall. As the material collides with the wall, it forms small pellets that are then continuously discharged from the rim of the disk. Disk pelletizing machines are commonly used in the iron ore industry to produce iron ore pellets. They provide a cost-effective and efficient way to transform fine iron ore powder into solid pellets suitable for further processing.

3. Rolling Drum Pelletizing Machines

Rolling drum pelletizing machines, as the name suggests, utilize a rotating drum to agglomerate material into pellets. The drum consists of a series of inclined flights or lifters that pick up the material and drop it as the drum rotates. The repeated lifting and dropping action creates a tumbling effect, allowing the material to form into small pellets. These machines are used in the agriculture industry for pelletizing animal feed, as well as in the pharmaceutical industry for creating uniform particles for tablet production.

4. Fluidized Bed Pelletizing Machines

Fluidized bed pelletizing machines use a fluidization process to transform powdery materials into spherical pellets. The material is suspended in a stream of air or gas, providing fluid-like behavior. As the material interacts with the fluidizing medium, it agglomerates and forms pellets of uniform size and shape. These machines are commonly used in the chemical and pharmaceutical industries and are particularly suitable for heat-sensitive materials. The fluidized bed process allows for precise control over pellet size and density.

5. Centrifugal Pelletizing Machines

Centrifugal pelletizing machines take advantage of centrifugal force to create pellets from fine materials. The machine consists of a rotating base with a series of holes and a stationary knife system. The material is fed into the rotating base, and centrifugal force pushes it against the holes. As the material passes through the holes, the knife system cuts it into pellets of the desired size. Centrifugal pelletizing machines are used in industries such as food processing, where they are utilized for pelletizing cereals, grains, and snack foods.

The Benefits of Pelletizing Machines

Pelletizing machines offer numerous benefits across a wide range of industries. Let's explore some of the advantages they provide:

1. Increased Efficiency

By transforming bulk materials into pellets, pelletizing machines enhance efficiency in production processes. Pellets are easier to handle, transport, and store compared to powders or granulates. Their uniform shape and size allow for consistent feeding and dosing, reducing production errors and enhancing overall productivity.

2. Improved Product Quality

Pelletizing ensures that the final product has a uniform composition, size, and density. This is particularly important in industries such as pharmaceuticals, where the uniformity of tablets or capsules is crucial. Pelletizing machines enable manufacturers to produce high-quality products that meet strict industry standards.

3. Enhanced Material Handling

Pelletized materials flow more easily and have improved handling properties compared to powders or granulates. They can be easily pneumatically conveyed or mechanically transported, reducing the risk of material loss or segregation. The flowability of pellets also facilitates dosing and mixing processes, making them ideal for applications that require precise material proportions.

4. Economical Resource Utilization

Pelletizing machines enable manufacturers to make use of low-value or waste materials, transforming them into valuable products. For example, in the biomass industry, pelletizing machines convert agricultural residues, forestry wastes, or energy crops into biomass pellets, which serve as a renewable energy source. Similarly, in the plastics industry, pelletizing machines can recycle plastic waste into high-quality plastic pellets for various applications, reducing the ecological footprint.

5. Versatility and Adaptability

Pelletizing machines are versatile and can be adapted to suit different materials and manufacturing processes. With the ability to control pellet size, shape, and density, manufacturers can tailor the pellet properties to meet specific requirements. This adaptability allows pelletizing machines to serve diverse industries, including plastics, agriculture, chemicals, food processing, and more.

Conclusion:

Pelletizing machines lie at the heart of modern production processes, enabling industries to efficiently transform raw materials into value-added products. With their ability to produce uniform and easily handled pellets, these machines offer a myriad of benefits such as increased efficiency, improved product quality, enhanced material handling, economical resource utilization, and adaptability. From plastic pellets to iron ore pellets and biomass pellets, the applications of pelletizing machines are vast and vital to various sectors. As manufacturing industries continue to evolve and strive for improved productivity, the significance of pelletizing machines will only grow, solidifying their position as a crucial element in the production landscape.

There are a wide variety of which are scientifically tested to have positive effects on the ability to extruder machine manufacturers. plastic extruder machine manufacturers Application is one of them.

If you are looking for a reputable Application extruder machine manufacturers, you are on the lucky side as we are among the leading supplier in China. Visit the given links TENGDA Extruder Machine Manufacturers to know more.

If something seems too good to be true, then it can be a , which provides plastic extruder machine manufacturers value over its cost.

People tend to want what they perceive they cannot have. Making TENGDA seems exclusive or as if it will go out of stock if they don't act quickly often makes it more enticing to the consumer and increases the likelihood that they will buy in.