What is the difference between pelleting and pelletizing?

There is often confusion between the terms 'pelleting' and 'pelletizing' as they both refer to a method of creating small, compacted pellets for various applications. However, there are distinct differences between the two processes in terms of technique, equipment used, and the industries they cater to. Understanding these differences is important for industries and individuals looking to produce or utilize pellets efficiently and effectively. In this article, we will delve into the dissimilarities between pelleting and pelletizing, exploring each process in detail and highlighting their unique benefits and applications.

What is Pelleting?

Pelleting is a process that involves the compression of a material into small, dense pellets using a pellet mill or pelleting machine. The material to be pelletized can vary widely, including but not limited to agricultural residues, biomass, animal feed, and industrial byproducts. Pelleting is widely used in the agriculture and animal feed industries to transform raw materials into high-quality feed pellets that are easy to handle, transport, and store.

The pelleting process begins with the material being fed into a pellet mill where it passes through a series of rollers and dies. The rollers exert pressure on the material, forcing it to pass through the dies, which shape the material into small cylindrical pellets. The compression and heat generated during this process help to bind the particles together, producing strong and durable pellets. Once the pellets are formed, they are cooled and dried to achieve the desired moisture content before being ready for use.

Benefits of Pelleting:

- Enhanced Nutritional Value: Pelleting improves the digestibility and bioavailability of nutrients in animal feed, leading to better animal health and productivity.

- Reduced Transport Costs: Pellets have a higher bulk density compared to loose material, allowing for more efficient transportation and storage, ultimately reducing costs.

- Improved Handling: Pellets are uniform in shape and size, making them easier to handle, measure, and distribute.

- Reduced Waste: Pelleting can help minimize waste by processing and utilizing agricultural residues that would otherwise go to landfill.

- Extended Shelf Life: The compact nature of pellets helps to protect against moisture, pests, and degradation, thereby extending their shelf life.

What is Pelletizing?

Pelletizing is a broader term encompassing various methods of transforming materials into pellets, usually with the aid of a pelletizer or pelletizing machine. While pelleting primarily refers to the compression of a material, pelletizing involves other techniques such as agglomeration, extrusion, or sintering, depending on the characteristics of the material and the desired end product.

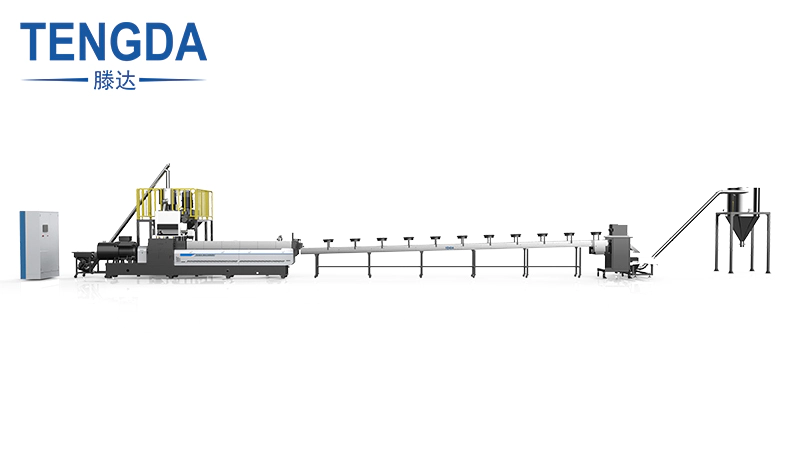

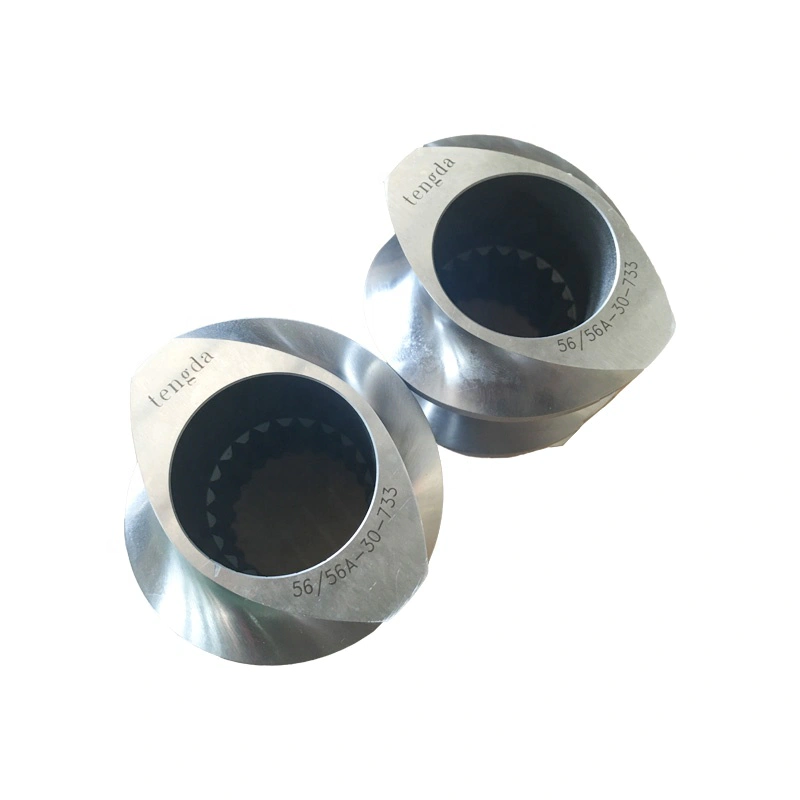

In the pelletizing process, the material is first prepared by crushing, grinding, or mixing it with binders or additives to improve its physical properties. The prepared material is then fed into a pelletizer, which may use different mechanisms to form the pellets. For instance, in agglomeration, small particles are made to adhere or clump together to form pellets, while extrusion involves pushing the material through a die to create pellets of specific shapes. Sintering, on the other hand, involves heating the material to cause fusion, resulting in denser pellets.

Benefits of Pelletizing:

- Versatility: Pelletizing allows for the transformation of a wide range of materials, including plastics, metals, minerals, and chemicals, into pellets suitable for diverse applications.

- Customization: Different pelletizing techniques can be employed to achieve specific properties, such as size, shape, hardness, and porosity, tailored to the requirements of the end product.

- Improved Performance: Pelletizing processes often lead to enhanced material properties, such as increased strength, reduced dust formation, and improved flow characteristics.

- Waste Utilization: Pelletizing provides an effective method for recycling and reusing waste materials, reducing environmental impact and promoting sustainability.

- Resource Efficiency: By transforming raw materials into pellets, pelletizing can improve the efficient use of resources, such as reducing energy consumption during transportation due to higher bulk density.

The Key Differences:

While both pelleting and pelletizing involve the production of pellets, there are several key differences between the two processes. These differences relate to the materials processed, the techniques employed, and the specific industries they serve.

Materials Processed:

Pelleting is primarily used for materials such as agricultural residues, biomass, and animal feed, whereas pelletizing encompasses a much broader range of materials, including plastics, metals, minerals, chemicals, and even pharmaceuticals. The diversity of materials that can be pelletized makes pelletizing a more versatile process suitable for various industries.

Process Techniques:

Pelleting involves the compression of material through the use of rollers and dies, with heat and pressure facilitating densification and binding. On the other hand, pelletizing employs different techniques such as agglomeration, extrusion, or sintering, depending on the material and its properties. This distinction allows pelletizing to achieve a wider array of pellet characteristics compared to pelleting.

Industry Applications:

Pelleting finds extensive application in the agriculture and animal feed industries, where feed pellets are in high demand for livestock and aquaculture. It is an essential process for converting raw materials into nutritionally balanced and easily consumable feed. Pelletizing, on the other hand, caters to a broader range of industries including plastics manufacturing, metallurgy, mining, and chemicals, where pellets are utilized for various purposes such as injection molding, smelting, ore dressing, or as intermediate products in chemical processes.

Choosing the Right Process:

Selecting the appropriate process, whether pelleting or pelletizing, depends on the specific requirements and objectives of the industry or individual. Factors such as the type of material, desired pellet characteristics, target application, and economic viability should all be taken into consideration.

Pelleting:

Pelleting is the preferred option when dealing with agricultural residues, biomass, or animal feed. It ensures optimal nutrient retention, improved animal health, and economical transport and storage of feed materials. The use of dedicated pellet mills and well-established pelletizing techniques in the agriculture and animal feed industries makes pelleting the go-to process for producing feed pellets at scale efficiently.

Pelletizing:

Pelletizing, with its broader range of techniques and material suitability, serves industries beyond agriculture and animal feed. It enables the transformation of various materials into pellets with tailored properties to meet specific industry requirements. From plastic pellets used as feedstock for manufacturing to metal pellets used in metallurgical processes, pelletizing provides versatility and customization options for a wide array of applications.

Conclusion

In conclusion, although the terms 'pelleting' and 'pelletizing' may seem interchangeable, they refer to distinct processes with different techniques, equipment, and applications. Pelleting primarily focuses on the compression of agricultural and feed materials, producing durable feed pellets with enhanced nutritional value and reduced handling and storage costs. Pelletizing, on the other hand, encompasses various methods and materials, allowing for versatility and customization to meet specific industry requirements. Whether it is the production of feed pellets for livestock or the creation of plastic pellets for manufacturing, understanding the differences between pelleting and pelletizing is crucial for industries seeking efficient and effective pellet production.