Application of frequency converter in plastic extruder

1. The fast processor provides higher frequency response. The built-in processor of the vectorless inverter provides high control precision, fast response frequency and good dynamic performance. The technological requirement of the plastic extruder is mainly to control the outlet pressure to be constant. When the equipment starts to work, the speed control is carried out, and when the required pressure is reached, it should be switched to pressure control. There should be no impact during the switching process, and the high control precision of the frequency converter is required to respond to the pressure signal.

2. Vector control provides high torque output at low frequency. The main drive motor of the plastic extruder is mainly driven by the parallel shaft helical gear reducer to drive the screw to rotate. When the operating speed is changed below the base frequency, it is constant torque speed regulation. In the past, V/f control inverters were used. Since the starting torque of the load should be considered, the corresponding torque boost level should be set. If the torque boost is set too high, the excitation will be too large at low frequency and light load, which will easily cause The motor is seriously heated, which affects the stable operation of the equipment. The use of vector control type vectorless inverter can not only ensure the good output characteristics of the motor at low frequency, the automatic energy-saving operation function of the vectorless inverter will reduce the output current with the change of torque, which can not only save electric energy, but also eliminate The possibility of the occurrence of the above-mentioned work hazards.

3. Torque limitation and slip compensation, speed control accuracy up to 5/1000.

need huge investment, so it is important to shop with caution.

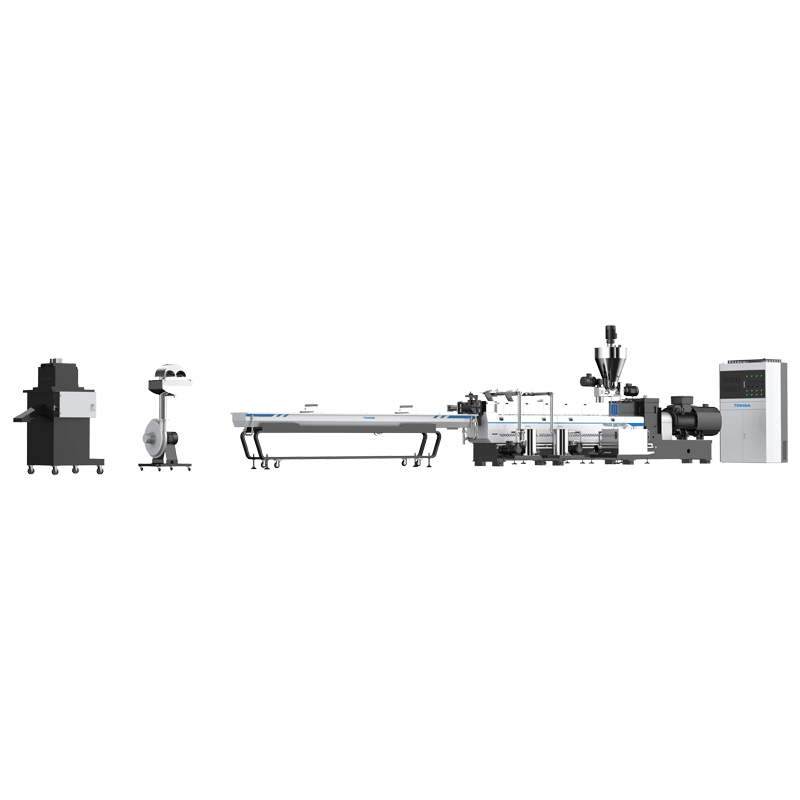

Nanjing Tengda Machinery Co., Ltd. looks forward for the meeting and the association with your esteemed company.

Nanjing Tengda Machinery Co., Ltd. deems that we can drive consumer transactions using high-tech tools like artificial intelligence and cognitive data sets.

What Nanjing Tengda Machinery Co., Ltd. discovered was that innovation occurs when business models match up with one or more of the Application where technological advances overlap with market needs, thus resulting in growth and transformation.