Biodegradable plastics on the stage of 2022 Winter Olympics

The 2022 Winter Olympic Organizing Committee was held in Beijing. With the support of the concepts of "Green Olympics" and "developing Olympics", adhering to the sustainability vision of "sustainability and going to the future", the use of biodegradable tableware in the preparation of the Games will help to amplify the positive impact of the environment with the help of the international force of the Winter Olympic Games.

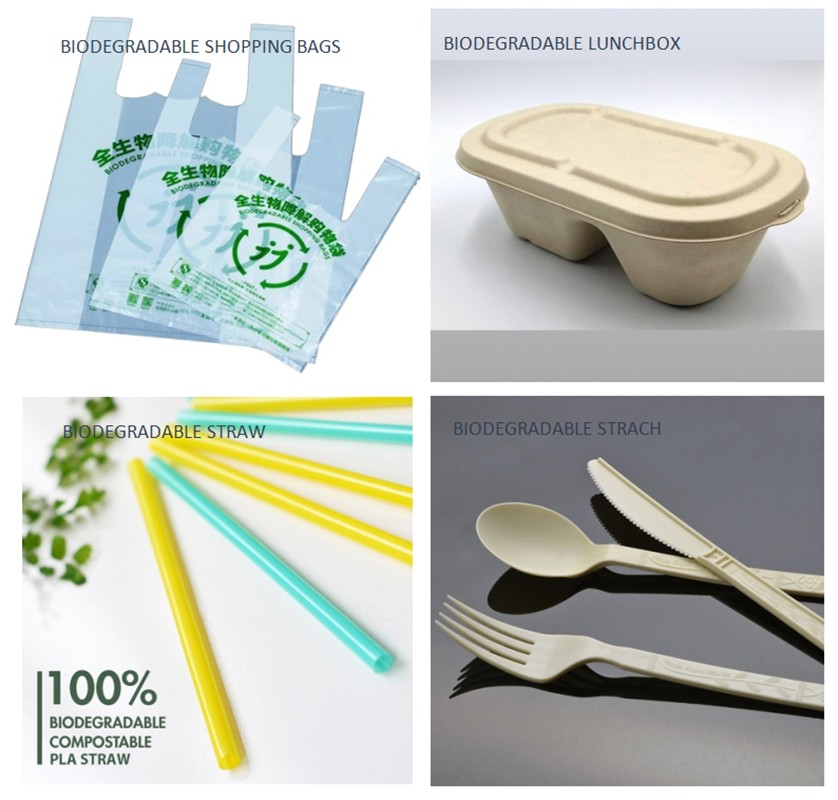

Biodegradable materials are widely recognized and vigorously developed as "green ecological materials" in the current market. Theoretically, biodegradable materials can be transformed into harmless carbon dioxide and water in nature under the action of natural microorganisms such as bacteria, molds and algae.

The main raw material of degradable tableware is biodegradable material polylactic acid (PLA), which makes the heat resistance of the product reach 120 ~ 130 ℃ through the self crystallization behavior of the material itself. Its performance is far higher than that of the most common polystyrene (PS) composite material in the market and can be completely comparable to polypropylene (PP) products.

In addition, compared with traditional plastic products, the incineration of degradable tableware will not produce toxic and harmful gases to pollute the atmosphere during the treatment process; Landfill will not occupy a large amount of land for a long time, resulting in white pollution, land pollution and other problems; The processing process does not need pre sorting, which simplifies the processing links and saves the cost of human resources; After being buried for 6 ~ 8 months, compost can be metabolized by microorganisms in the soil and finally degraded into harmless carbon dioxide and water.

Nanjing Tengda Mechanical Equipment Co., Ltd. is a Chinese high-tech enterprise focusing on the R & D, production and sales of complete sets of plastic machinery equipment. After more than ten years of intensive research and innovation, a complete set of automatic polymer processing production line based on twin-screw extruder has been formed, as well as the independent production of high-end key spare parts. A complete industrial chain has been established in terms of R & D, design, manufacturing and application. In 2020, Nanjing starch degradable plastic molding equipment Engineering Research Center was established by Nanjing development and Reform Commission.

Tengda PLA/PBAT/PBS etc. Biodegradable granules production line

1. It is equipped with high torque or ulta-high torque gearbox. Decelleration and torque distriution are intergrated, new structure design. Imported zero-stress safety coupling can be selected.

2. It adopts high wear-resistant and corrosion-resistant barrel and screw and high-strength mandrel.

3. It adopts air-cooling strand pelletizing system, the unit has reliable performance and the operation is easy.

‘Equipment stability is very important in operation and use. It can also measure whether the design of a device is a good one.’ Zhang Jili, general manager of Nanjing Tengda Mechanical Equipment Co., Ltd., made an example, "we are like making a pot. Our customers produce rice. The pot cannot be changed every day, but rice should be eaten every meal." In his opinion, high quality is made through fine quality management, accelerating innovation, constantly improving production technology and formula to provide high-quality products to meet the needs of different customers. Different from the general tailor-made, Tengda meets the requirements for accuracy and quality according to the customer's use environment, process and product type, which far exceeds the general concept of making products.

Tengda continuously introduces the latest automation technology to realize the double improvement of production and marketing. "The quality of employees is important, but compared with the significant upgrading of automation level, the stability and continuity of equipment production are stronger and the product quality is higher. When intelligent manufacturing is truly achieved, it can more comprehensively, accurately and timely grasp the current situation and development trends of all links in the manufacturing process, establish and improve the data information sharing mechanism, and make production faster and more convenient. ”Zhang said. Focus on the requirements of customer excellence, create every product with the attitude of communication, and serve every customer with heart. Along the way, Tengda has paid a lot, including sweat, failure。But more is the trust and recognition from customers.