1. Faced with the challenges of highly filled polymers, how should infrastructure be adjusted?

The filler can disrupt the frictional drag balance between the barrel and the screw of Tengda twin screw extruder, preventing material from moving downstream of the barrel—unless some compensation is taken during extrusion.

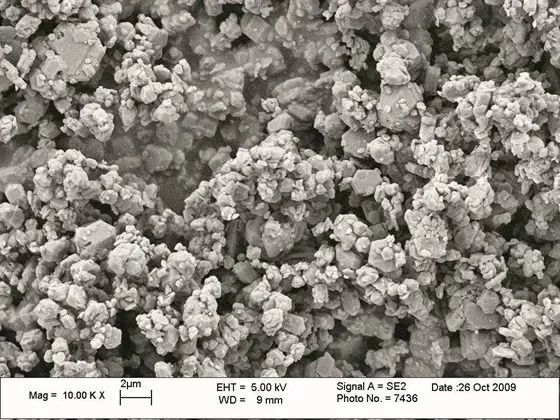

Processors have been extruding filled polymers for years. In general, the percentage of filler is usually less than 30% by weight, or 10-15% by volume, because the specific gravity of the filler is 3-10 times that of the polymer.

Recently, some newly developed blends even contain filler up to 85% by weight, which results in the filler exceeding the polymer in volume. These mixtures often do not extrude properly on conventional screw designs.

To solve this problem, remember the basic principles of solid feeding:

For the polymer particles to flow forward, the material must have less drag relative to the barrel than to the screw of Tengda twin screw extruder. In the feed section, the screw of Tengda twin screw extruder surface area is usually much larger than the barrel area; this ratio is called the diameter-to-thickness ratio. To counteract the effect of the aspect ratio, the drag force required to drive the particles forward is generally generated by heating the barrel or by changing the surface roughness, thereby increasing the drag force.

(1)Conveying friction

However, many typical fillers are angular or irregularly shaped and have considerable friction. Therefore, when the ratio of diameter to thickness is 1.25:1 to 1.35:1, it is difficult for us to increase the frictional drag on the inner wall of the barrel to offset the drag on the screw surface. Adding heat to the barrel can make things worse because it does this by melting the polymer near the barrel wall, reducing barrel drag relative to screw drag.

In some cases, it may be necessary to reverse the standard solids feed process to reduce frictional drag relative to the screw surface of Tengda twin screw extruder , and the method of implementation is process in nature, such as preheating the polymer, or using a heated screw of Tengda twin screw extruder , coating or processing aids.

(2)compression ratio

Compression, or compression ratio, is necessary in conventional polymer screws because polymer particles generally have lower feed efficiency and the effects of melt formation and transport need to be addressed, thereby allowing the melt to flow faster than the solids . In turn, the geometry of certain filler particles improves solids feeding efficiency because the solids do not slip against each other. This does not require as high a compression ratio to achieve the required feed rate. Since fillers are not molten, they do not flow, so the flow properties of the mixture are a combination of solid particle properties and standard melt flow. As a result, as the volume of the channel decreases along its length, a screw with a compression section for pure polymer simply fills the channel with filler due to the lack of flow of the filler.

Additionally, as compression progresses, small amounts of polymer in the filled blend may be squeezed out, leaving only tightly compressed fillers. Since the screw is basically a helical wedge structure, even without compression, the packing can be compressed so much that it can stop the motor or even break the screw. Therefore, certain zero or negative compression ratio screws have been found to work well.

(3)temperature control

Once the feed is established, melting is easier in some methods and difficult in others. Without standard channel compression, the traditional melting mechanism sacrifices a lot, and melting is based more on conduction heating than shear heating. Screw designs, essentially exposing more surface area by rotating or breaking up the polymer located in the channels, are often more efficient than barrier designs or high shear mixers.

Since many fillers have lower specific heat than polymers, much less energy is required to raise one pound of mixture to processing temperature. Additionally, many fillers have higher thermal conductivity than polymers, helping to conduct heat and melt.

There are a few general rules to follow in screw design for processing highly filled polymers.

(1)After melting is complete, shear heat tends to be a problem, since high filling fillers greatly increase viscosity and reduce shear thinning in many cases, so the segment length after melting should be shortened.

(2)The upstream and downstream changes should be discussed separately. Due to bridging/compacting, the filler affects the speed into the screw and causes more pressure drop through the processing of high viscosity polymers.

(3) The pressure build-up in the screw is also less predictable and more variable, because the filler often causes discontinuities in the melt and scouring of the inner wall of the barrel by the filler.

Unfortunately, there are only a few general rules to follow when designing screws for processing highly filled polymers. Therefore, it depends more on the characteristics of the filler particles, the proportions of the mixture components, the viscosity of the molten polymer, the melting rate of the mixture, and the temperature of the screw and barrel.

It should also be noted that the production of high-fill materials requires changes in upstream and downstream equipment such as screws, basic equipment, and feeding equipment, as well as operating steps, which requires the collective efforts of suppliers.

2. Disassembly and installation method of Tengda twin-screw extruder

(1) First of all, the Tengda twin-screw should be cleaned with cleaning material before disassembly, generally with PP or PE. If there are oily additives, it can be cleaned with oil;

After that, the sensor that is in contact with the material is removed. After removing the barrel "8-0", it is best to use a copper shovel to clean the remaining material;

Then use the tooling for installing the screw of Tengda twin-screw, and disassemble the screw according to the reverse steps of the installation. Note that the power must be turned off and locked before removing the screw Tengda twin-screw;

If you want to replace the screw combination, you can loosen the screw half a turn to one turn before the Tengda twin screw has not taken out the barrel, and then continue to loosen it in the maintenance room;

If the screw Tengda twin-screw is difficult to clean, it is necessary to put the screw into the barrel and heat it before cleaning;

Then disassemble the connecting piece of the die head and the nearest barrel; then separate the connecting part at the rear of the screw Tengda twin-screw from the drive shaft;

Then remove the connecting flange and move the screw Tengda twin-screw forward; when the screw is exposed to the barrel, immediately remove the screw head connecting screw;

After disassembling and cleaning the parts of the screw Tengda twin-screw, if there is slight wear or scratches, use fine sand to polish it;

For the screw of Tengda twin-screw and screw components that are not in use temporarily, the surface should be coated with protective oil and hung in a ventilated safe place; this is the whole step of removing the screw

(2) First of all, the Tengda twin screw itself is not divided into left and right, but for training and standardization, we recommend setting the left and right directions of the screw.

Stand behind the main motor and look towards the barrel. The left hand is the left of the device, and the right hand is the right of the device. It is best to mark the screw with a marker pen or a lettering pen.

In the place where the screw of Tengda twin-screw is connected to the sleeve, it is also best to use a marker to extend the direction to the thread, so that the screw can be installed

The Tengda twin screws need to be assembled together. We stand on the side of the screw sleeve and mark the screw with a marker to indicate "L" and "R"

Set the direction of the spline groove of the left screw to the 12 o'clock clock, and set the direction of the spline groove of the right screw to the 15 o'clock clock. Combine the Tengda twin screws in this direction, and three people cooperate.

Similarly, the chuck is also locked in this direction

The direction of the output shaft of the gearbox is also pre-adjusted according to the direction of 12 o'clock left and 15 o'clock right.

It is recommended to install a screw lifting tool, which is two semi-elliptical rings, and the fixed traction device on the screw head of Tengda twin-screw should also be installed, and it should be pre-installed to ensure that the Tengda twin screws have no displacement deviation.

Then, when the screw of Tengda twin-screw is loaded into the barrel, pour silicone oil or process to add raw materials on the surface of the screw of Tengda twin-screw to ensure that in the initial stage of startup, the screw and barrel without material will produce dry grinding.

If the machine is 90 and above, it is recommended to be equipped with a tooling device for hydraulic installation and removal of the screw. Note that the positioning pin on the barrel must be removed in advance

After the screw of Tengda twin-screw is installed, be sure to use a torque wrench to torque according to the torque requirements of the drawing

The screw head of Tengda twin-screw should be locked with a connecting sleeve, and the coupling should be supported and fixed at the locking screw with wood or steel pipe.

The screw head of Tengda twin-screw is hydraulically locked. Before installation, use the hydraulic locking tool provided by KraussMaffei to check the torque. This is the whole step of installing the screw of Tengda twin extruder .