Say "goodbye" to clogged die holes in underwater pelletizing! Three adjustments to reduce downtime for cleaning.

Extruders are increasingly using underwater pelletizing for the production of engineering polymers, including resins such as PET, nylon and polycarbonate. These resins have "difficult" properties such as low viscosity and/or rapid cooling or high melt temperatures.

Compared to strip pelletizing, underwater pelletizing offers the advantages of good pellet quality, high automation and low cost. However, there is a greater risk of die freeze in the production of engineering resins such as those mentioned in the previous paragraph than in less sensitive commercial resins such as polyethylene, polypropylene or polystyrene.

Underwater pelletizers typically use circular die heads with 10 to 20 holes or even hundreds of holes. Systems can be designed for compounding anywhere from a few hundred to nearly 20,000 lbs/hr. (Even larger pelletizers are used for extrusion production.)

![]()

Causes of extruder machine mold hole freezing

Extruder machine die hole diameters are typically 0.125 inches, but can be as small as 0.01 inches or as large as 0.20 inches for smaller particles. Output per extrusion hole is about 25-100 lbs/hr, but the average 0.125 in. die hole produces about 30 lbs/hr.

The key to underwater pelletizing is to deliver enough thermoplastic through the extrusion die hole to keep the extrusion hole at the melting temperature of the resin while the melt and extrusion die head are in contact with water that is several hundred degrees cooler. An extrusion metal die is a very good heat conductor, so unless there is sufficient polymer flow through the extrusion die hole, the water will cool the extruder hole and the polymer will solidify in it. However, the processor does not immediately know that this blockage has occurred.

The problem is that if one or more extruder mold holes are clogged with polymer, the efficiency of the extruder die head is reduced. Eventually, the clogged hole will interfere with the flow of the surrounding holes and the finished pellet will become larger and irregularly shaped, decreasing yield. Eventually, the line needs to be shut down completely to clear the extruder die holes.

There are three main causes of extruder mold freezing: improper start-up sequence of polymer and water flow and cutter operations; inadequate mold heating and insulation and process fluctuations. Failure to consider the material formulation (resin, filler level and filler type - heat absorption or thermal conductivity) can also cause problems. But you can't change the recipe to please the cutter; it should be designed to run most recipes.

Adjusting the pelletizer start-up process

Most extruder die hole freezing occurs during startup, when the resin, cooling water and cutter must start in the correct sequence. If resin begins to flow through the extruder die and the cutter engages before the water reaches the extruder die face, smearing and resin blockage can occur outside the hole in the water tank. If water reaches the extruder die face before the polymer begins to flow, excessive cooling can cause the hole to freeze.

In the early days of underwater pelletizing systems, extruder skilled operators controlled this sequence manually. Starting in the early 1990s, start-up can be automated and controlled by a commercial PLC control system. Polymer diverter valves and process water bypass systems allow the PLC to more precisely control the timing of polymer and water entry into the extruder die. Pelletizers manufactured since the mid-1990s offer automated cutting systems using hydraulics, pneumatics and servo motors to control cutting pressure. As a result, today's fully automated systems can control the start-up sequence in fractions of a second.

Optimized extruder mold design

Once the line is up and running, most mold freezes can be avoided by maintaining a very constant flow of material through the extrusion mold holes. But some freezing problems are related to the extruder mold design itself.

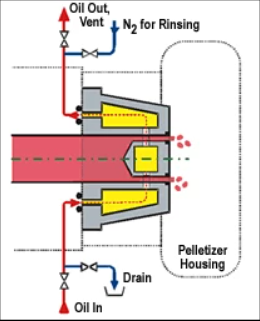

Extruder molds are heated by electric cartridge heaters or hot oil. The electrical heating will not be completely uniform because the cartridge is placed primarily in a ring around the extruder mold hole, near the outer edge of the mold plate. As a result, the extruder holes around the outside of the cartridge tend to be hotter than the extruder holes in the center. (Mold manufacturers have tried adding cartridges to the center of the mold, but the engineering proved clumsy.)

As a result, cartridge heaters may not be suitable for large molds or materials with a narrow melting temperature range, such as nylon, which may tend to freeze in the center of the mold.

Oil heating applies more uniform heat over a larger area than cartridge heaters. Oil systems are configured with up to eight mold zones. However, oil heating is more expensive than cartridge heaters. Oil heat is typically used in high output lines for resin manufacturers or large co-mingling plants. More recently, it has been used on smaller systems for better temperature control.

If the oil valve is clogged, the mold hole in the affected area of the mold will become colder and possibly freeze, but the rest of the mold will be fine. The output may not change at first. Again, as with cartridge heaters, the problem will manifest itself as defective particles.

All tube cores have some type of insulation. Most molds use a special plate attached to the middle of the mold face. But the plates may come loose. Water then flows behind them, cooling the mold and possibly causing freezing.

Another method of insulation is to use a "hollow" mold design that contains a vacuum gap. It can be retrofitted to most systems if not part of the original mold design. The vacuum is a good insulator and cannot be damaged like a solid insulating board.

Reduce process fluctuations

Any type of extrusion process interruption or output fluctuation can lead to freezing. For example, extruding low bulk density recycled material can cause fluctuations and fluctuations in the extruder output, which can lead to inconsistent polymer flow that can freeze the die hole in a random manner. Polymer melt pumps can be used to prevent these fluctuations and provide consistent die head flow.

The use of a discontinuous slide screen changer can also cause flow interruptions and trap air, resulting in a temporary loss of polymer flow to the extruder die hole. This can lead to random freezing of the extruder die bore. The solution is to use a continuous extruder screen changer, which allows for instant replacement of dirty screens without interrupting the process or trapping air.