After decades of development, at present, domestic resins are more likely to choose a variety of die surface hot cutting lines, and underwater cutting is the most popular one. Why do Tengda choose die face pelletizing? The following six points can solve your doubts!

1. Process and principle of die face pelletizing

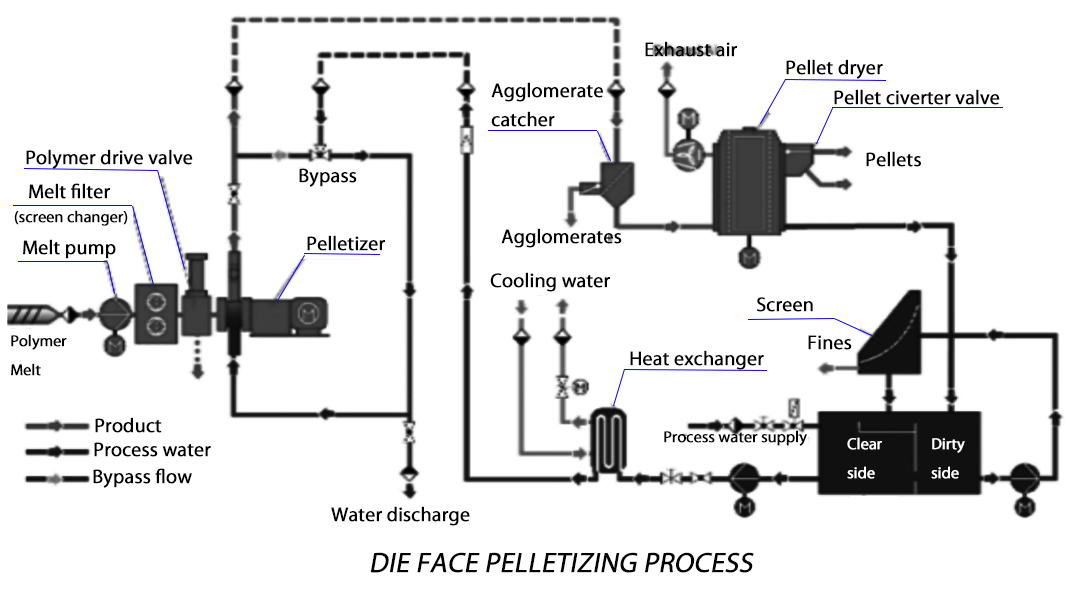

As shown in the figure below, in the Tengda die face pelletizing technology, the pelletizing system mainly includes the following equipment: reversing valve, cutting chamber, template, pelletizer with drive system, cooling pipeline, and dryer including water system, vibration Sieve etc. With the continuous improvement of single-line production capacity, the maximum capacity of the pelletizer currently used in the production of SAN pelletizing and ABS pelletizing is as high as 10,000kg/h or more.

The main working principle of the Tengda die face pelletizing system is that the material is transported to the start-up valve and cutting chamber through the bottom pump or gear pump, and the material is cut by the driven pelletizing motor knife in the molten state, and then the particles are cooled in the process water. The water is generally 40-60°C, the particles are sent to the dryer by the process water for drying, the process water is self-circulated to the water system for filtration, and then returned to the process system for recycling after heat exchange.

2. Structure of Tengda die face pelletizing

The products produced by Tengda die surface cutting are round or elliptical particles. The production process is high temperature cutting, the surface of the particles is rapidly cooled, and the internal heat can be used for drying the particles themselves, and the temperature of the process water is not high. The Tengda pelletizer itself occupies a small area, making full use of the air space to complete the arrangement of cooling pipes, and the total floor space can be reduced to 3-6m. Tengda die face pelletizing can be installed on different floors, avoiding straight line arrangement to save space.

The particles are cut in a molten state, and the surface is rapidly cooled and then transported in a cooling pipe and a dryer. The contact method of round or elliptical particles is point-to-point contact. The contact between the particles and the pipeline and the dryer has no edges and corners during the transportation process. The possibility of dust generation is reduced, and the dust content is reduced by about 10% to 15%. The dust is low, and the cyclone separator can not be installed at the outlet of the dryer.

The Tengda die face pelletizing system is a closed system, no need to install suction equipment, no pollution to the environment, and no additional auxiliary waste gas treatment equipment is required, which has an important improvement in equipment investment and environmental protection to a certain extent. Changing the template, changing the blade may require a small amount of waste. The time to replace the template is 15 to 30 minutes, and the time to replace the blade is about 5 minutes.

3.Advantages of Tengda die face pelletizing operation

Usually, multiple operators are required to start the Tengda pelletizing under the water, and the Tengda die head is very easy to break. Only one operator is needed to start the pelletizing on the die surface. Once Tengda die face pelletizing is successfully started, the operation stability of the equipment is much higher, and there is basically no abnormal shutdown.

There is a very high degree of automation in both Tengda water-drawn strand pelletizing and Tengda die-face pelletizing. Compared with die surface granulation, the lifespan of commonly used spare parts may be slightly shorter than that of die surface granulation, and the die head hole will produce variegated substances during the production process, which requires the operator to stop the production line regularly, and the die head The replacement of the board will cause the loss of raw materials and increase the production cost. The frequency of replacement of spare parts by the operator may be slightly higher.

04 Advantages of Tengda die face pelletizing products

In the production process of Tengda underwater strip cutting, the strip material cut by the moving knife already has a certain hardness, and it is easy to generate dust, while the Tengda die surface cutting is formed by the blade cutting the melt at the die head, which is generated during cutting. The amount of dust is much less than that of the water-drawn granulation; the bulk density of the round particles is larger, the contact area between the particles is smaller, and less dust is generated.

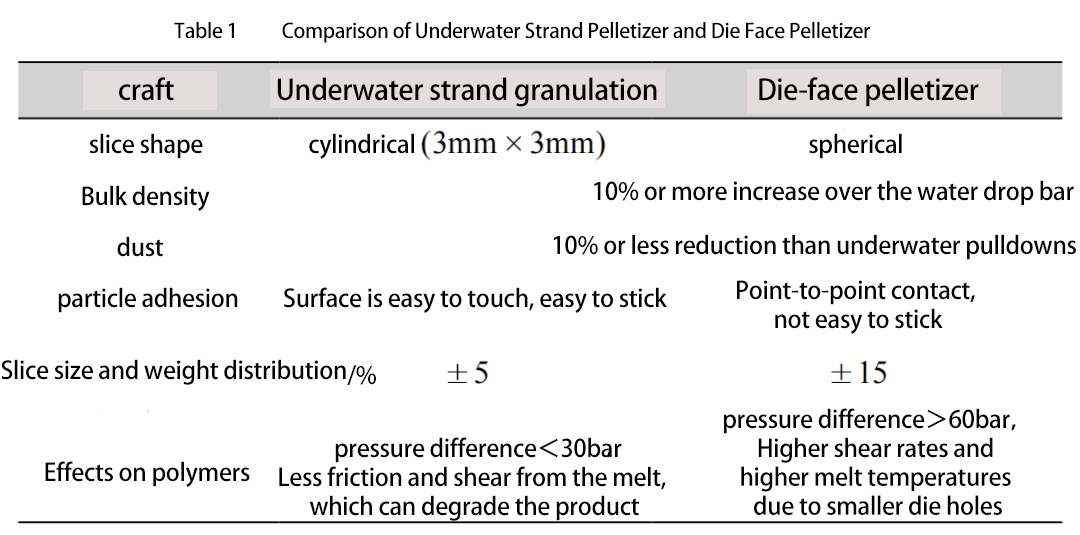

Compared with the cylindrical particles after slicing under water, the round particles have no edges and corners, so it is not easy to generate dust when rubbing against each other, while the cylindrical particles slicing under the water are prone to generate dust. The particles melt at a more uniform speed and use less energy. The specific comparison is shown in Table 1.

5. Cost advantage of Tengda die face pelletizing

The cost of the Tengda die face pelletizing blade is very low, because the blade material is ordinary, and the hardness requirement is not high, and the Tengda die face pelletizing die head can be repaired after use, which greatly saves the cost.

The material of the Tengda die-cutting water tank should be thickened, so that the water tank is not easily deformed, the wear of the rollers will be reduced, and there is no need for excessive maintenance costs in the later stage.

6.Application of Tengda die face pelletizing

The production of SAN resin is widely used in die-cutting. Based on the particularity of the Tengda die-cutting process and the characteristics of the SAN resin material itself, the main problem in the production process is that there are more powders entrained in the SAN resin. In addition, the material selection standard of the water tank needs to be improved. If the material selection standard is too low, the material is not thick enough, the hardness is not enough, and it runs for a long time, the roller in the water tank is easily deformed, the roller wears more, and the service life will be reduced. It will be damaged and the equipment cannot operate normally, so it needs to be shut down for maintenance, and the production load will be adjusted accordingly, which will bring a lot of trouble to production. Increased costs.

The toughness of ABS resin is relatively high, so the cutter selection is different from that of SAN resin. Usually, an oblique knife with an angle is used. The specific material should be determined according to different grades. 80~120bar, the inlet pressure of the screen changer is 180~220bar, and the inlet pressure of the booster pump can be positive pressure, which is generally satisfied by the co-rotating twin-screw extruder.

“Tengda Machinery” will create excellent quality twin-extruders machines, and if you are interested in any of our products or wanting to get more information about the twin-extruders machines of TENGDA, please don’t hesitate to contact us directly for more information. TENGDA will serve you wholeheartedly forever! If you need the invitation of this exhibition, you can also contact TENGDA, TENGDA will send it to you in time. We are looking forward to your joining in Blending Smart Manufacturing 2022 in Suzhou!