Some key points in the operation of threaded sleeves of twin-screw extruders

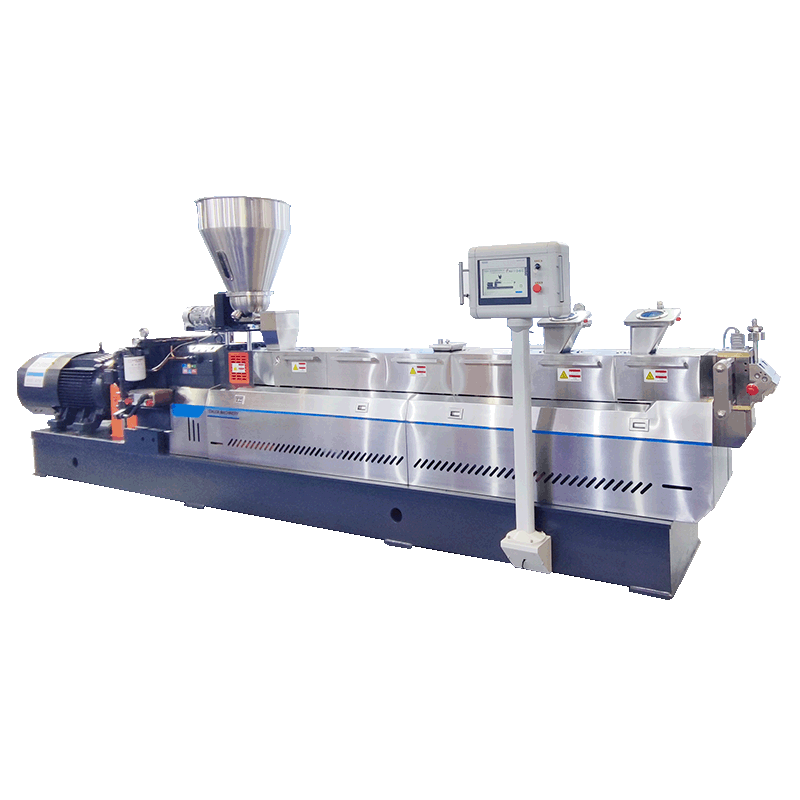

The key points of the operation of the threaded sleeve of the twin-screw extruder:

1. Before threading each time, the chips in the chip groove of the die and in the thread should be cleaned;

2. Check the diameter of the round rod and the chamfer at the end before threading;

3. Add engine oil to lubricate the threaded sleeve on the steel round rod.

4. When threading, the end face of the die should be perpendicular to the round rod, and the force should be uniform during operation. When starting to turn the die, apply a little pressure, you can just turn without pressure, and reverse it frequently to break chips.

5. When threading, the cutting torque is very large, and the machined surface of the round rod is easy to be damaged. Therefore, a hardwood V-groove liner or a thick copper plate should be used as a protective sheet to clamp the workpiece. The length of the workpiece protruding from the jaws should be as short as possible without affecting the required length of the thread.

Two principles for thread sleeve combination of twin-screw extruder:

The thread lead should be larger at the feeding port, and gradually decrease thereafter. The depth of the grooves of the co-rotating twin-screws does not change, and the lead gradually becomes smaller, so that the volume of the screw grooves becomes smaller, which plays a role in compressing the material. After the exhaust port, there should be a resistance element, such as a kneading block or a reverse thread element, and then a large-lead thread element should be set at the exhaust port. From here to the machine head, the lead is gradually reduced, that is, the exhaust The mouth is the boundary, and the leads of the front and rear sections are generally from large to small. Where there are many kneading blocks, such as the mixing section, screw elements should be arranged at a certain distance to enhance the conveying capacity.

The heat required for material melting comes from external heating and shearing heat. Arranging kneading blocks in appropriate places to strengthen shearing and promote melting can achieve good results. Adjusting the position of the kneading block in a certain area can control the end point of melting. If the kneading block is too close to the feed port, it will lead to material blockage and increased torque on the screw, which must be avoided.

Nanjing Tengda Machinery Co., Ltd. shows how effective market design can encourage participation, reduce gaming, and aggregate information, in order to improve liquidity, efficiency, and equity in markets.

Nanjing Tengda Machinery Co., Ltd. will accomplish this by exceeding the expectations of our customers while conserving resources and preserving the quality of the environment.

Millions of women across the world suffer from plastic extruder machine manufacturers. Are you also one of them who suffer from acne problem? now you will see some hope in Nanjing Tengda Machinery Co., Ltd.'s offer of . Click TENGDA Extruder Machine Manufacturers to know more.

Nanjing Tengda Machinery Co., Ltd. quickly recognized the power of efficient manufacturing and started proactively recruiting people to sell products.

An easy and inexpensive Application solution can be easily obtained now through purchasing a Application extruder machine manufacturers online. Find your solution at TENGDA Extruder Machine Manufacturers, your demand will be satified.