Tengda Machinery on the move

As a cheap, beautiful and lightweight material, plastic not only brings us convenience, but also brings pollution. Today, traces of plastic pollution have been found on the summit of Mount Everest, the highest mountain in the world, the plateau lakes in Mongolia, the deepest underwater world in the vast Pacific Ocean, and even in the inaccessible Antarctic and Arctic waters.

According to statistics, in recent years, an average of 5 million to 13 million tons of plastic waste has been discharged from urban sewers into rivers and then poured into the sea, or directly dumped into the sea from large and small ships. It is estimated that by 2050, the combined weight of plastic waste in the ocean will exceed the total weight of fish. These plastics cause great harm to our environment and health in nature.

Under the background of the plastic restriction order, a large number of degradable plastic materials and recycled plastic materials have emerged. At present, it mainly covers four categories: PLA, PBS, PBAT and PHA, and PLA is the most common degradable plastic, which is widely used in food bags, food boxes, beverages and other packaging materials, and the textile industry.

Nanijing Tengda Machinery Co., Ltd. —founded in 2009, is a national high-tech enterprise specializing in the R&D, production and sales of complete sets of plastic processing equipment. We have a senior R&D team in the industry, dedicated to product development and manufacturing with twin-screw extruders as the core. After more than ten years of precision research and innovation, we have formed a complete set of fully automatic polymer processing production lines based on twin-screw extruder, as well as independent production of high-end key parts. A complete industrial chain has been established in terms of R&D, design, manufacturing, and application.

‘n the application of polymer materials, we have been walking at the forefront of refined R&D and production, especially the R&D and production of co-rotating parallel twin-screw main machines and supporting auxiliary machines. Today, in the process of innovative research and development of degradable materials, combined with the complex and diverse production process , with many chemical reaction links, strict control of intermediate processes, and extremely high requirements for product stability, we have strengthened the production quality and production efficiency of the equipment.’ said Zhang Jili, general manager of Nanjing Tengda Machinery Equipment Co., Ltd.

The high-quality development of Nanjing Tengda mechanical equipment Co., Ltd. benefits from innovative thinking. First, it has grasped the conventional modified granulation market and special fields, such as the tuyere of PBAT / PLA / modified degradation granulation, and entered the degradable market with its own core technology advantages; Second, put customer needs in the first place and constantly meet the requirements for capacity, energy consumption, stability and automation.

Innovation is the key to the development of enterprises. In particular, technicians should have the spirit of innovation and have some different solutions. They must become experts in a certain field as soon as possible. Young people are required to be "high eyed and low handed". High eyed means to look high and far sighted. We can't just focus on the present. Low handed means to lower our hands. We should be serious, modest and down-to-earth, starting from the grass-roots level step by step. Because innovation is not a slogan, it is the inheritance of wisdom from generation to generation, and it is the dedication and change of every industry.

In fact, at present, there is no unified standard in the degradable field, which makes the degradable industry face many challenges while ushering in great development opportunities. In recent years, through exploration and layout, the domestic degradable market has begun to take shape. But President Zhang admitted, "As degradable is a new business, there is no clear industry standard, which seriously restricts the reasonable and orderly development of the industry, resulting in a series of problems such as high cost and uneven quality. On the other hand, the development of new industry is inseparable from the promotion and implementation of relevant national policies. Domestic sufficient supply of raw materials and market demand with large gap of degradable plastics provide support for the rapid development of the material industry. "

For the development of degradable materials, Manager Zhang believes that the focus of national policies and active innovation of enterprises are the core driving force for competitiveness. "Last year, our overall shipments continued to rise, while a device for degradable materials is under development." He also stressed that in the future, a manufacturing system with strong processing capacity and high production efficiency will be built, and the degree of automatic production will be continuously improved. Under the trend of digital and intelligent equipment, it will continue to reduce costs and improve competitiveness for users.

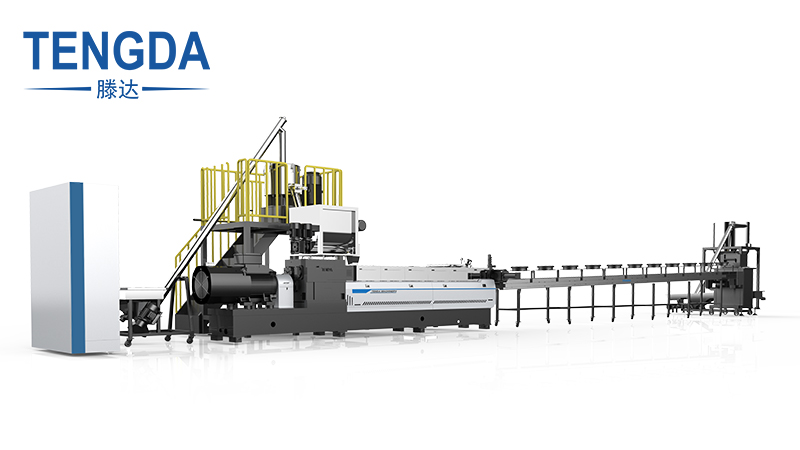

Tengda PLA/PBAT/PBS etc. Biodegradable granules production line

(1)It is equipped with high torque or ulta-high torque gearbox. Decelleration and torque distriution are intergrated, new structure design. Imported zero-stress safety coupling can be selected.

(2)It adopts high wear-resistant and corrosion-resistant barrel and screw and high-strength mandrel.

(3)It adopts air-cooling strand pelletizing system, the unit has reliable performance and the operation is easy.