On October 3,2019, the 19th Vietnam International Industrial Plastic Exhibition was held on schedule.

30,000 square 2,1,200 stalls, 800 exhibitors, from 18 countries, 25,515 purchasers. Vietnam International Plastic Industry Exhibition is a national mechanical industry exhibition with strong international nature, professionalism and trade in Vietnam. The exhibition was strongly supported by the Vietnam Ministry of Trade, Vietnam Industry Department, Vietnam Investment Planning Department, Vietnam Science of Technology and Environmental Protection and government departments and professional associations such as the Vietnam Machinery Association, Plastic Association and Mould Association.

Over the past decade, the 18th Vietnam International Plastics and Rubber Industry Exhibition(VietnamPlas) has grown to be the most well-known and reputed trade fair of the sector in the domestic Vietnam market. Co-organized by the industry leader Vietnam Plastics Association(VPA), VietnamPlas has officially become the go-to exhibition for making business contacts and upgrading manufacturing facilities. With the endorsement of Vietnam Rubber association(VRA) and Rubber Plastic Manufacturers Association(RPMA) and other international councils, VietnamPlas is well-prepared to deliver a satisfying result for all industry players.

Plastic products are widely used in our day-to-day lives, shoes, hi-tech product parts, accessories, plastic bags etc., and the expected export value growth is around 12 to 15 percent this year in Vietnam. The manufacturing capability of the region is barely catching up with the overwhelming demand from Japan, US, Europe and other countries, the implementation of smart production solution is what Vietnam in desperate need of, and that’s where VietnamPlas comes in.

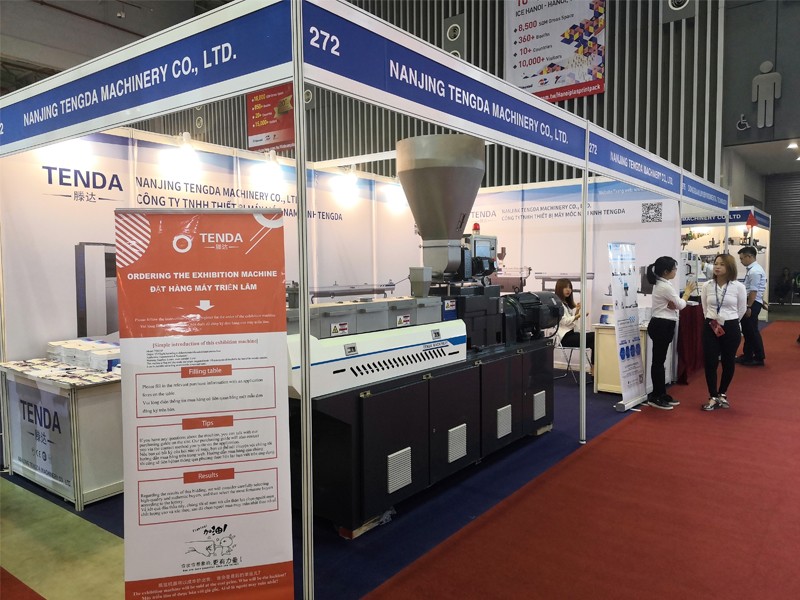

With the development of the company's foreign trade business, Nanjing Tengda also rushed to Vietnam to participate in the industrial plastic exhibition event. Nanjing Tengda Machinery is committed to the research and production of industrial twin screw extruder granule system. The Two-stage (Twin-screw/Single-screw) Compounding/ Pelletizing Extruder System unit exhibited in this exhibition was highly praised by the majority of exhibitors.

Two-stage (Twin-screw/Single-screw) Compounding/ Pelletizing Extruder System Characteristics.The first stage is the twin-screw extruder, which completes the transportation, high-effective plasticizing and compounding and strong shear dispersion. Because there is no machining head, the whole machining process is in a headless back pressure state, so that we can flexibly arrange screw combinations for different materials so as to achieve the best compounding state of materials, the strong shear overheating is avoided, and the production capacity is greatly improved;

The second stage is the low speed rotating single screw extruder, which can reduce the temperature and pressure of plasticized dispersed uniform material and granulate at low speed. This design combines the advantages of both extruders. It is widely used in granulation of various thermosensitive materials, large capacity

devolatilization, and one-step extrusion etc.

Decomposing the process function, adding the independent operation variables, and being beneficial to the optimization of each process step by step, higher efficiency and capacity. It is suitable for the processing of thermosensitive polymer materials such as various PVC cable materials, transparent materials, various PE cross-linking materials, PE shielding cable materials, sole foaming material, etc.