Countermeasures for Water Leakage in the Cylinder

Causes of leaks in the barrel

Due to poor welding of the end face of the Tengda extruder cylinder, there are blisters or pores, or pitting corrosion caused by long-term dissolved oxygen corrosion. Generally, the leakage point occurs in the cooling flow channel inside the cylinder or the welding point of the section.

If water leakage occurs, it is because the cooling water pressure is greater than the pressure in the low-pressure side of the Tengda extruder material cylinder, and the water will enter the cavity and gasify rapidly when it encounters high temperature. When extruding from the die, the gas will be released immediately, causing the strip to be broken and unable to be extruded normally. If the cooling water of the cylinder is turned off, the lack of cooling of the material will cause the temperature of the material in this section to remain high, affecting the quality.

Solutions

Generally, when this phenomenon is encountered, it is necessary to immediately stop and replace the Tengda extruder cylinder for welding. After welding, perform air pressure test, or dye flaw detection, or PT flaw detection. If there is no abnormality, it will be put into use. However, if there is production pressure, special measures can also be taken to continue production. For example, using compressed air or vacuuming to cool the material can continue production.

Solutions to the uneven mixing of high rubber ABS

Reasons for uneven mixing

The rubber and AS particles are mixed and melted in the Tengda extruder , and then extruded from the die head and cut into pellets. The products are then sent to downstream factories for injection molding to produce various final products. The main function of rubber in the product is to improve the impact strength and good elasticity, but if the rubber is mixed unevenly after injection molding, it is easy to form pits on the surface of the injection molded parts, which affects the strength and affects the appearance.

solutions

a. From the Tengda extruder operation level: reduce the temperature at the feeding end of the particles, increase the friction of the particles; increase the speed of the Tengda extruder screw; increase to improve the mixing effect.

b. Change the group type: increase the screw blocks in the Tengda extruder mixing section and reduce the Tengda extruder screw blocks in some conveying sections, thereby increasing the mixing; the grooves of the screw blocks are deep for conveying, and the friction between the material and the cylinder body with shallow grooves increases, which is beneficial to the material. Plasticizing to increase the molding effect.

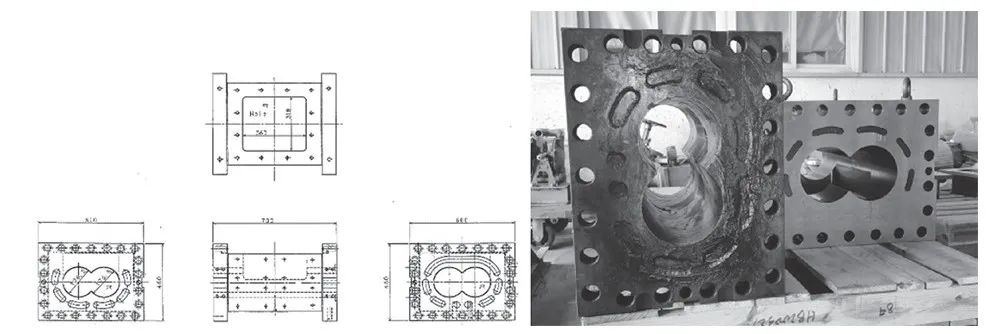

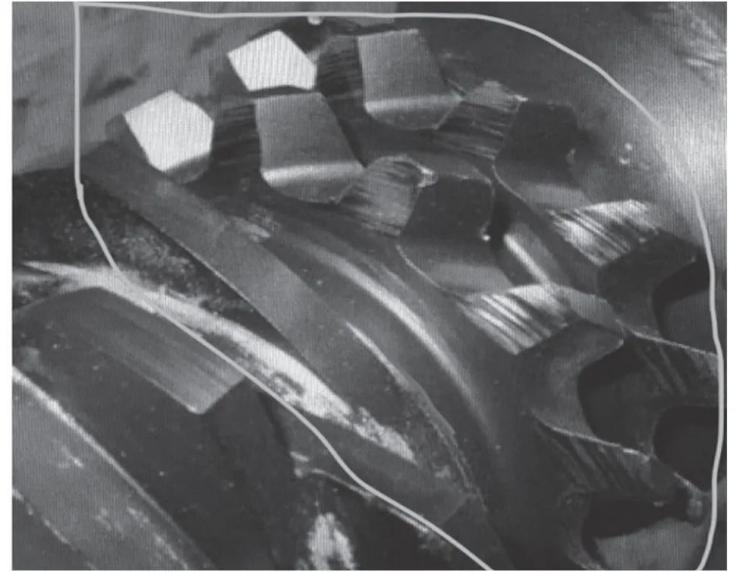

c. Add a new type of Tengda extruder toothed strong mixing screw

Note: Features of ZME threaded elements: ①Have good mixing function ②It is a single-head screw element

Precautions when installing ZME: ③ Spacer gaskets of at least 1mm must be installed between them when they are installed with double or triple screw elements. Otherwise, if the mandrel moves slightly in the longitudinal direction, a pair of screw elements at the same position on the two shafts may cause a collision and fight.

●The rationality can be seen in the engaging block. There is already a 1mm gap of Buit-in between two adjacent discs.

Screw block and barrel corrosion

cause

In the production of twin-screw extruder, if the material produced is acidic, it is easy to corrode under high temperature and high pressure. 10 times.

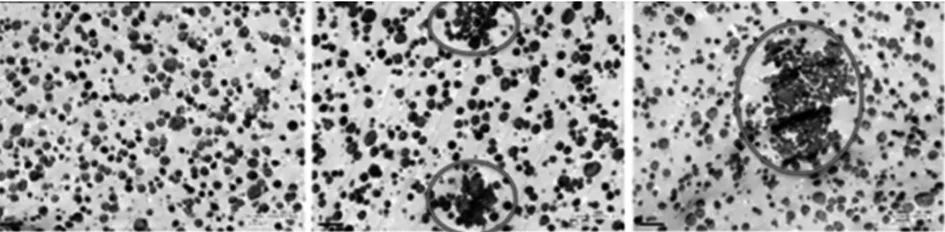

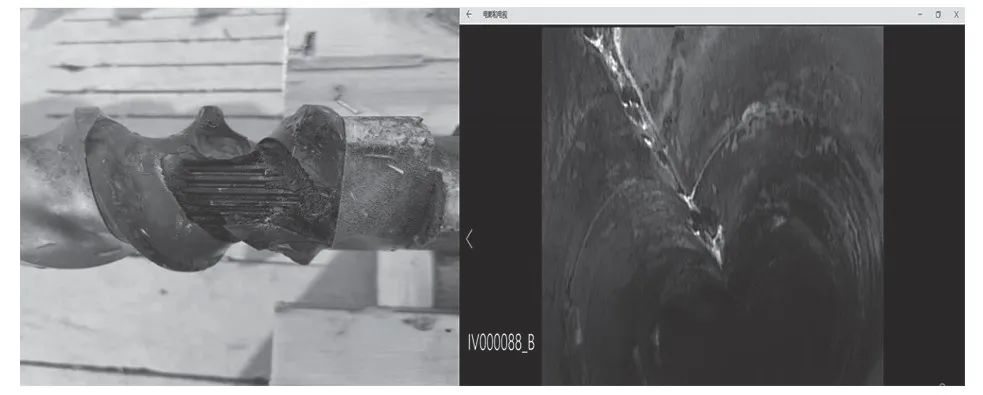

Corrosion diagram of screw block

It can be seen from the figure that the screw block is corroded and directly peeled off, and it is blocked when the material is transported to the screen changer, which can be found due to the change of the pressure in front of the screen. After extracting the screw, it was found that the screw also has a certain degree of corrosion, and if it continues to run, there is a risk of breaking the shaft. In order to prevent the peeled screw block from causing damage to the barrel, an endoscope was used to check it, and it was found that there were scratches on the inner wall of the barrel.

Preventive measures

In the case of unavoidable acidic environment, priority should be given to changing the material of the screw block, from the original only anti-wear material to a nickel-based alloy that is both anti-wear and anti-acid corrosion to increase corrosion resistance, and secondly consider increasing the frequency of maintenance to prevent corrosion. The ends are replaced regularly to reduce the subsequent adverse effects caused by peeling.

The product has heterochromatic particles

Causes of heterochromatic particles

Backflow of Tengda extruder vacuum waste liquid: After the material is melted, there is generally a gas phase residue, which is gasified after the volume expansion of the low-pressure section of the cylinder. The Tengda extruder vacuum port set here just uses negative pressure for extraction, because the gas will condense during the extraction process , the condensate may fall directly to the product due to the flat top of the Tengda extruder vacuum device, or flow back to theTengda extruder vacuum port along the pipeline. If the Tengda extruder vacuum port discharges the waste liquid groove or the collection tank overflows, the vacuum waste liquid will flow back. To the cylinder, the color difference particles are formed with the extrusion of the material.

solutions

a. Maintain the degree of Tengda extruder vacuum, generally controlled within 150 torr, and remote control can be performed appropriately.

b. The Tengda extruder vacuum device can be properly insulated to reduce the condensation of exhaust gas.

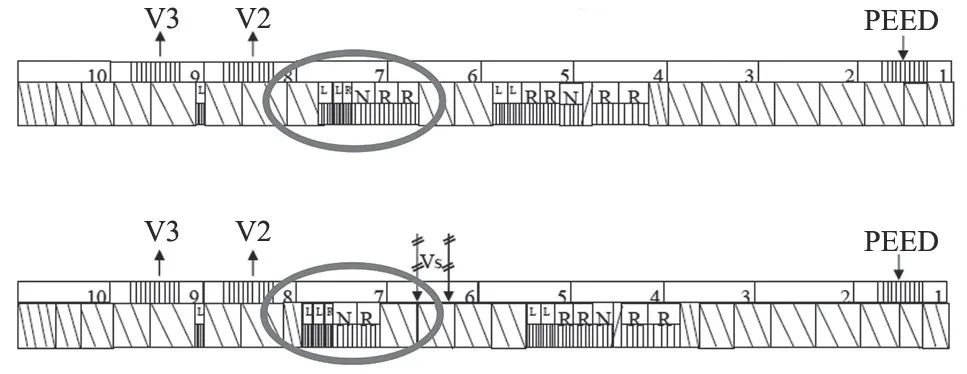

c. Change the flat top structure of the Tengda extruder vacuum port to bevel.

The Tengda extruder vacuum port turns the material, the output is too low and cannot be produced normally

Cause

Rubber BP powder contains a certain amount of water. During the process of conveying with AS particles from wide pitch to narrow pitch, after the compaction section, it is difficult for the water to escape backwards and can only move forward. When the material is continuously mixed During the smelting process, the temperature gradually rises until it melts, and the water is rapidly vaporized. At the Tengda extruder vacuum port at the low pressure end, if the negative pressure is insufficient or the water vapor is too much, the water vapor will bring out the molten material when it escapes, causing the Tengda extruder vacuum port to turn the material. the Tengda extruder vacuum exhaust pipe is blocked, which will affect the product quality, and may cause the machine to jump or even damage theTengda extruder .

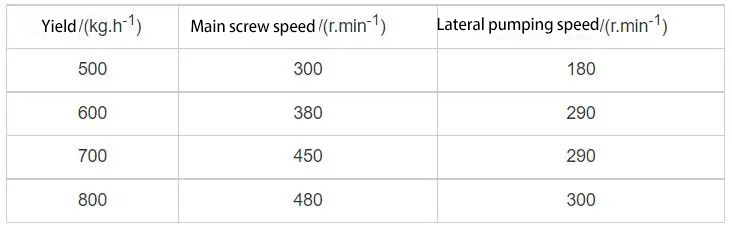

Simple calculation of water content: take a twin-screw extruder with an output of 800 kg/h as an example

Q water=800×30%×8%=19.2kg/h

1kg water vaporization volume expansion 1244.44L (1000L/18)×22.4=1244.44L

The total volume of water after vaporization V=19.2×1244.44=24m3/h

However, the actual capacity of the Tengda extruder vacuum pump on site is obviously insufficient, resulting in that the Tengda extruder water vapor cannot be quickly extracted.

solutions

a. According to the actual size of the Tengda extruder vacuum port, the size of the pipe diameter, the temperature of the water vapor at the inlet of the Tengda extruder vacuum pump and the degree of Tengda extruder vacuum, then consider the amount of air leakage, and the safe working condition of the Tengda extruder vacuum pump, and select the suction volume according to the design principle of the Tengda extruder vacuum pump to be 25m3 /m vacuum pump (one vacuum pump with 4 production lines, there is a certain margin).

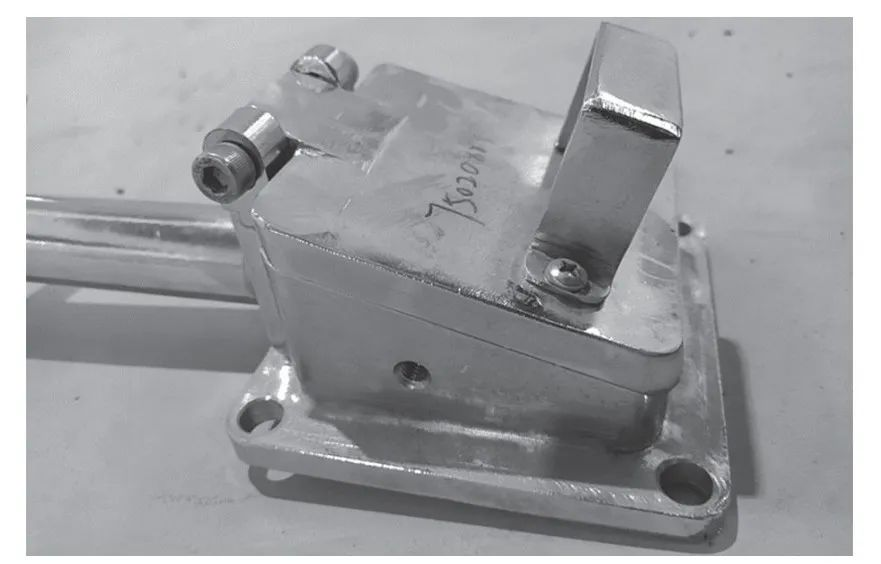

b. Add a side air extraction device, adjust the rotational speed of the air extraction screw and the rotational speed of the main Tengda extruder screw, increase mixing to increase the air extraction effect, and then gradually increase the output. The final production process is as follows: