What are the methods of repairing the plastic extruder screw

TG welding is the most commonly used method in the manufacture and repair of plastic extruder screws. Since the intense localized heat of TG causes some dilution of the base material, it is necessary to apply a second coat to achieve the full hardness of the hardfacing material.

Maintenance method two,

The structure of the PTA torch has an electrode in the center, surrounded by a double-walled tube, which sends metal powder. Hydrogen circulates around the welding area through this ring sulfur channel to provide a shielding gas egg around the argon arc area, and at the same time, the metal powder is not metered out through the holes in the inner wall of the tube.

1. The MG process has the advantages of high precipitation rate and excellent welding quality, but it can produce more basic material dilution than other processes. Therefore, it is necessary to apply a second layer of welding to achieve the required hardness.

2. In the MIG welding process, an arc is established between the workpiece and the wire electrode, which is continuously conveyed by the wire conveyor through the welding torch. The arc is continuously melted to form a weld pool, and the suitable gas or mixed gas covers the welding area to avoid air pollution.

Maintenance method three

1. Oxyacetylene welding requires high skill to obtain high-quality deposits, and the process is very slow. The advantage of oxyacetylene welding is that it provides base material dilution for non-laser methods. One coat of deposit is usually sufficient to achieve the desired hardness.

2. In the oxyacetylene welding process, a violent flame is generated by igniting a controllable mixture of oxygen and acetylene gas. The gas is discharged from the respective gas source through the pressure regulator. Introduced into a torch for mixing, then discharged from the tip and ignited. Flame strength depends on gas flow rate, gas mixing ratio, properties of the selected fuel gas and type of welding tip used. The weld is formed by the weld pool established by the contact of the flame, the workpiece, and the electrode.

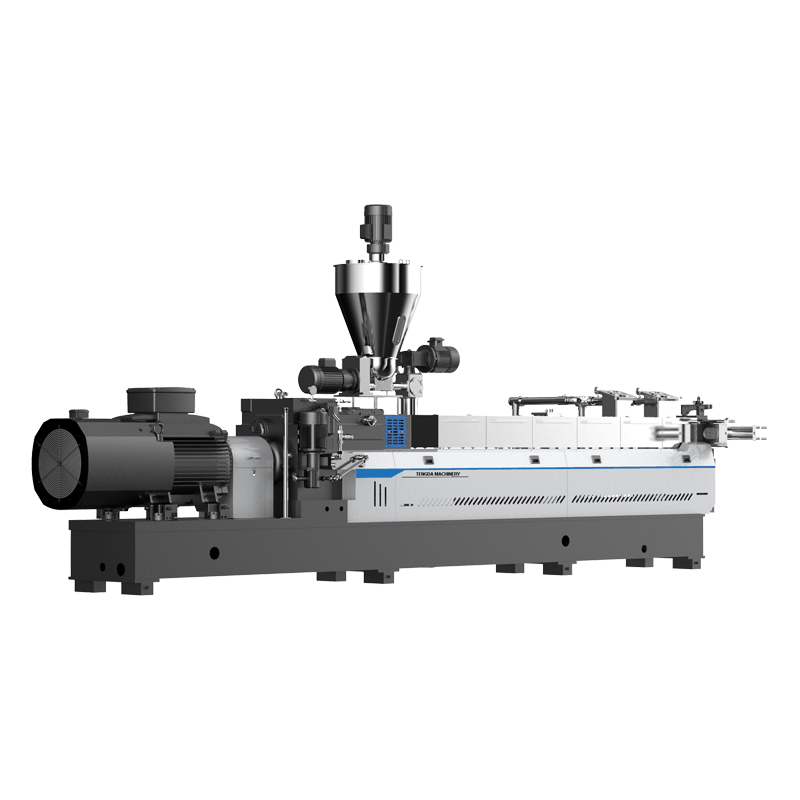

Most people who see a in operation for the first time are amazed at how well the plastic extruder machine manufacturers is managed.

Above all, we expect to be a credit to the communities we serve, a valuable resource to our customers, and a place where our dedicated Application can grow and prosper.

Application developed from Nanjing Tengda Machinery Co., Ltd.’s unique skills in high technology has helped to produce Applicationextruder machine manufacturers.