What is the reason for the slippage of the screw of the twin-screw granulator?

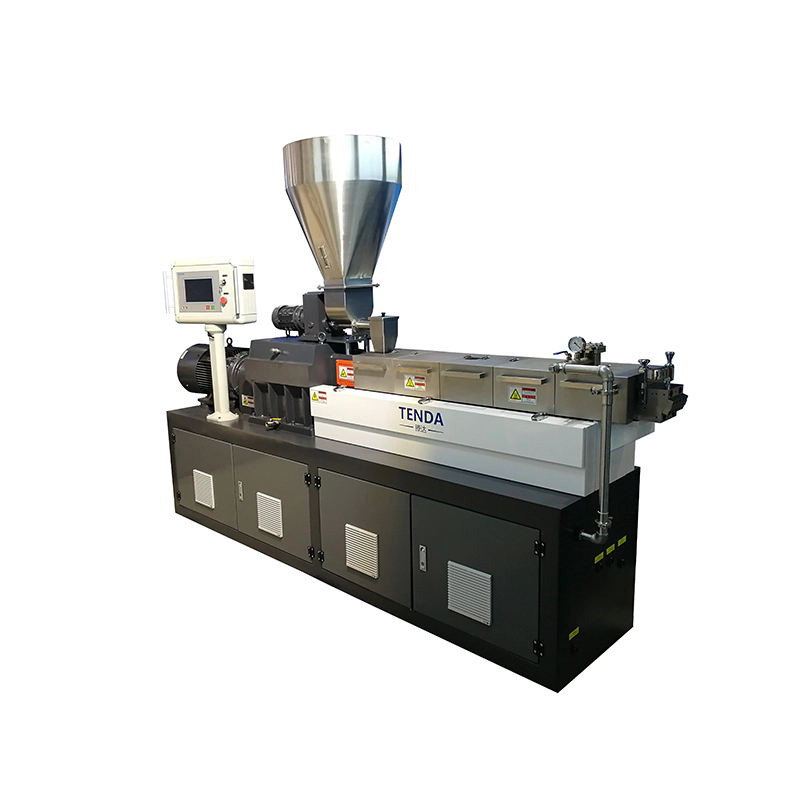

The twin-screw granulator is mainly used for filling, blending, modifying, adding, chlorinating, processing of polypropylene and superabsorbent resins of rubber, plastic and engineering resins.

The reasons for the slippage of the twin-screw granulator screw are:

1. Barrel or screw wear: Same as the feeding section, when the resin melts in the screw compression section, it adheres to the barrel wall. When the screw rotates, the material breaks away from the barrel wall and is transported forward after being sheared. If there are wear areas on the screw and barrel, the screw will not be able to move material forward effectively.

2. The second half of the barrel is overheated or overcooled: at the rear of the feeding section, the material forms a thin layer of molten polymer during the heating and shrinking process. The molten film layer is attached to the barrel. Without this thin layer, the pellets would be difficult to transport forward. The material in the feeding section must be heated to a critical temperature in order to form a critical molten film layer. But often the residence time of the material in the barrel is too short to allow the polymer to reach this temperature. The occurrence of this situation may be due to the small scale of the equipment and the corresponding equipment with smaller barrels and screws. If the residence time is too short, it is easy to cause polymer melting or insufficient mixing, which will cause the screw to slip or stall.

3. The back pressure is too high: If the back pressure is set too high, the screw may not be able to produce enough pressure to transport the melt forward to overcome the back pressure of the back pressure, and the screw will rotate in a certain direction without retreating, so Will do more work on the melt and significantly increase the melt temperature, which can adversely affect the quality of the finished product and cycle time.

4. Improper design of the hopper: The correct design of the hopper is the key to ensure the stable transportation of materials. Generally speaking, new pellets of uniform size work well in square hoppers with abrupt constriction zones. However, this is not the case when adding recycled materials. The shape and size of the pellets are very different by breaking again, which affects the uniformity of the feed. Incoherent feeding means that the screw cannot maintain a uniform delivery pressure on the melt, and slippage occurs.

5. When processing hygroscopic materials: Improper material drying will significantly reduce the viscosity of the material in the barrel and generate water vapor, making it difficult for the screw to transport the material forward.

6. Failure of the non-return ring: When the screw is rotating and plasticizing the material, the non-return ring should be in the front position and contact the fixed ring seat. If the non-return ring is in the backward position, or in a position between forward and rearward, the molten polymer will have resistance as it passes through the gap between the non-return ring and the ring seat. If you suspect that there is a problem with the check ring, you should replace it immediately.

TENGDA saves time and increases productivity because it's one of the most complete sources of business and contact information.

Nanjing Tengda Machinery Co., Ltd. will continue to bring our industry nuances of style and approaches to Application which are consistent with our evolving aspirations.

The plastic extruder machine manufacturers Application is also available as a extruder machine manufacturers.