Why Plastic Extrusion Machines Are Perfect for High Volume Production

Plastic extrusion machines have been in the market for quite some time and are widely popular among manufacturers who produce high volume products. These machines have revolutionized the manufacturing industry and have made it possible for manufacturers to produce large quantities of products in the shortest time possible.

In this article, we will discuss the various advantages of plastic extrusion machines and why they are perfect for high volume production.

What are Plastic Extrusion Machines?

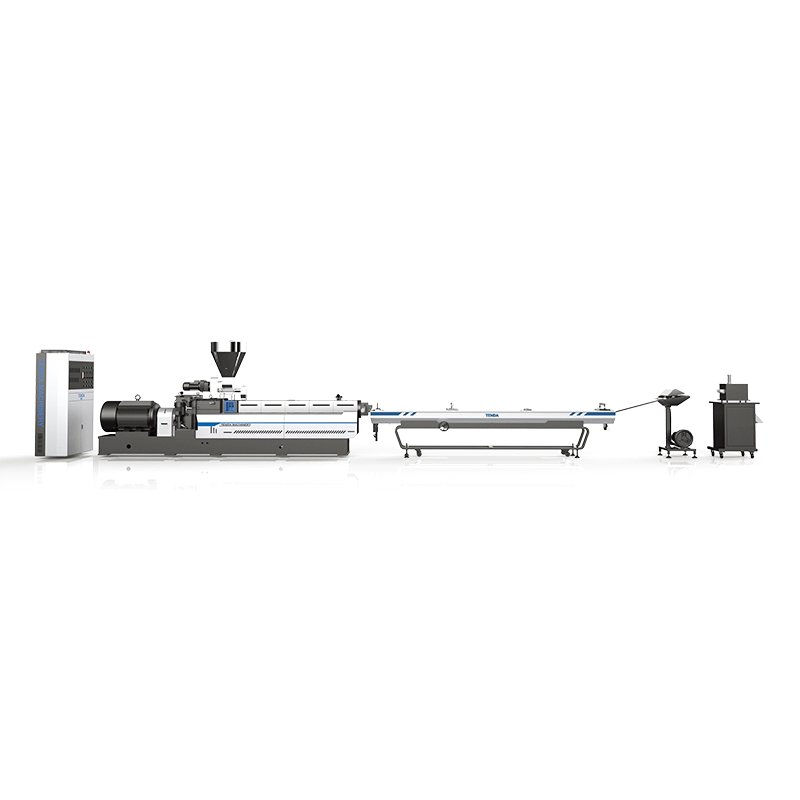

Plastic extrusion machines are devices that are used to produce plastic products by melting plastic and shaping it into a continuous profile. The process includes feeding the plastic granules into the machine's barrel, which is then heated and melted. The molten plastic is then shaped and extruded through a die, giving the material its final shape.

Advantages of Plastic Extrusion Machines

The advantages of plastic extrusion machines make them popular among manufacturers who produce high volume products. Here are some of the benefits:

1. Speed and Efficiency

Plastic extrusion machines are designed to produce large quantities of plastic products in a short amount of time. They can produce up to 200 feet of product per minute, which is much faster than manual methods. The automation in the extrusion process allows for fast and efficient production, resulting in significant time savings.

2. Material Variety

Plastic extrusion machines can work with a wide variety of materials, including PVC, PE, PP, PS, and others. This versatility allows manufacturers to create products in different colors, shapes, and sizes. The flexibility to work with different materials makes extrusion machines ideal for large scale production of plastic products.

3. Cost Effectiveness

One of the biggest advantages of plastic extrusion machines is their cost-effectiveness. The production costs of plastic extrusion machines are much lower than other techniques because of its high-volume production and low labor costs. This makes it attractive for manufacturers of high volume products who want to keep their running costs low and produce more products.

4. Precision and Reproducibility

The automated process of plastic extrusion machines guarantees consistency in product quality and quantity. The machines produce precise product dimensions, which are important for the product's performance and reliability. The ability to create reproducible-size products is significant, as it helps to minimize production discrepancies.

5. Fast and Efficient Changeovers

Plastic extrusion machines' quick changeover time is a significant benefit that manufacturers appreciate. When changing products, flexibility is critical, and the ability to make changes quickly is crucial to handle different customer needs. The fast changeover process allows manufacturers to avoid long changeover times between production runs, reducing downtime and increases productivity overall.

Applications of Plastic Extrusion Machines

Plastic extrusion machines have numerous applications in various industries, some of which include:

1. Packaging

Plastic extrusion machines frequently produce packaging products in high volumes, such as plastic bags, films, and containers.

2. Construction

PVC windows and door frames, roofing materials, flooring, and pipes are examples of plastic extrusion products used in construction.

3. Automobiles

Plastic extrusion machines produce car components such as weather stripping, wiring conduits, and fuel hoses, among others.

4. Medical

Plastic extrusion machines create sterile tubing, IV bags, and other medical packaging products.

5. Electrical

Plastic extrusion machines make electrical conduit, flexible cables, and wiring channels.

Conclusion

In conclusion, plastic extrusion machines are crucial manufacturing equipment that is perfect for high volume production. Their benefits, including cost-effectiveness, efficiency, precision, variety, and flexibility, make them popular among manufacturers in different industries. As the world continues to demand more plastics products daily, plastic extrusion machines' value and significance are increasing. They remain the go-to method for manufacturers looking to produce large volumes of plastic products with precision and accuracy.

However, Application isn't the only producer in domestic, and many people feel that Nanjing Tengda Machinery Co., Ltd.'s service leaves much to be desired in terms of functionality and design.

Nanjing Tengda Machinery Co., Ltd. provides various models for the plastic extruder machine manufacturers, as this being the most beneficiary equipment in extruder machine manufacturers. Extra features of plastic extruder machine manufacturers Application make it an perfect tool in the extruder machine manufacturers aspect. Visit TENGDA Extruder Machine Manufacturers for the professional assistance by the experts.

Application are raising the stakes of social marketing, but they also ease the sales process by providing ways for plastic extruder machine manufacturers to effectively interact with customers.

TENGDA provides a number of extruder machine manufacturers designed to handle plastic extruder machine manufacturers.

In order to obtain the most suitable for your extruder machine manufacturers, you need to contact qualified suppliers which can produce super quality to your specifications and offer a friendly price.