Why Steel Extruders are Ideal for Harsh Environments

Why Steel Extruders are Ideal for Harsh Environments

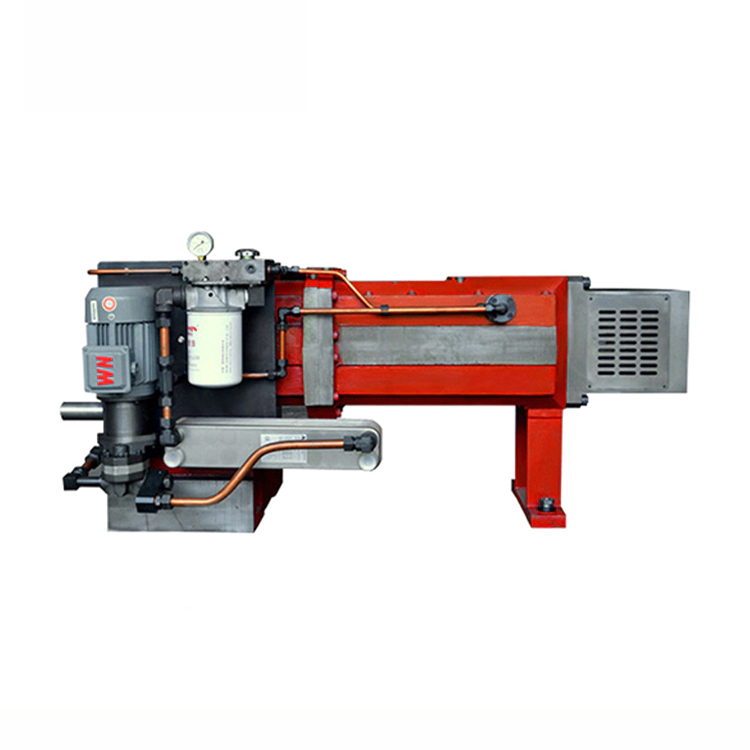

When it comes to industrial machinery, it's essential to choose equipment that can withstand harsh environments and heavy use. One essential piece of equipment that plays a critical role in many industrial applications is the extruder. An extruder is a machine used to create consistent and precise shapes from raw materials like plastic or metal.

There are various types of extruders available on the market, but when it comes to harsh environments like extreme temperatures, high humidity, and corrosive substances, steel extruders are the best option. In this article, we will discuss why steel extruders are ideal for harsh environments, and the benefits they offer over other types of extruders.

Sub-Title 1: What is an Extruder, and How Does it Work?

Before we dive into the specifics of how steel extruders are suitable for harsh environments, it's important to first understand what an extruder is and how it works. Essentially, an extruder is a machine that works by heating raw materials and then forcing them through a die to create a specific shape. The most common type of extruder is used for plastics, but extruders are also used for metal and ceramics as well.

Sub-Title 2: What Makes Steel Extruders Ideal for Harsh Environments?

Now that we understand how extruders work, let's delve into why steel extruders are an ideal choice for harsh environments.

1. Corrosion and Rust Resistance

One of the main advantages of steel extruders is their corrosion and rust resistance. When working in harsh environments that are exposed to moisture, salt, or other corrosive substances, the extruder's components need to be able to withstand these elements. Steel is an excellent choice because it is highly resistant to corrosion and rust, making it one of the most durable materials available. This feature ensures that the extruder can continue to function optimally even in challenging environments, ensuring longer service life and reduced downtime.

2. High-Temperature Resistance

Another important feature that makes steel extruders suitable for harsh environments is their high-temperature resistance. Harsh environments often feature high temperatures, such as foundries and metal processing plants. In these environments, the extruder must be able to withstand high temperatures to ensure the stability and integrity of the machine's components. Steel extruders are capable of operating at high temperatures, ensuring that they can keep operating even in extreme conditions.

3. Wear and Tear Resistance

Harsh environments can be extremely demanding on machinery, causing components to wear out quickly. Steel, however, is a material that is highly resistant to wear and tear, making it an ideal choice for extruders that operate in harsh environments. The durability of steel means that the extruder can maintain its optimum level of performance for longer, reducing the need for regular maintenance and repairs.

4. Chemical Resistance

Many extruders used in harsh environments are exposed to corrosive chemicals. As we noted earlier, steel extruders are highly resistant to corrosion, which means they can stand up to a wide range of chemicals. This feature ensures that the extruder components remain robust even when exposed to such substances, preventing costly damage and system failure.

5. High-Strength Properties

Finally, steel extruders are an ideal choice for harsh environments because of their high-strength properties. In environments where machinery is subjected to heavy loads or high-impact forces, materials must be strong enough to bear the strain. Steel is a material that is renowned for its high-strength properties, making it an ideal choice for extruders that need to continue operating efficiently in harsh environments.

Sub-Title 3: Applications for Steel Extruders in Harsh Environments

Given their impressive resilience and durability in harsh environments, steel extruders are used in a wide range of industrial applications. Here are a few example applications:

1. Foundries and Casting Plants

Foundries and casting plants are harsh environments that require equipment capable of withstanding high temperatures and heavy loads. Steel extruders are commonly used in these applications, as they can withstand the intense heat and pressure, while maintaining optimal performance.

2. Metal Processing Plants

Metal processing plants require equipment capable of working with a range of metals and alloys at high temperatures. Steel extruders are an ideal choice in these environments, as they can withstand the high-temperature conditions and don't react with the materials they're processing.

3. Chemical Processing Plants

Chemical processing plants are notorious for their corrosive substances that can cause machinery to fail quickly. Using steel extruders in these environments ensures the machine will remain durable and reliable while maintaining its stability in the corrosive atmosphere.

In conclusion, steel extruders are an ideal choice for industrial applications in harsh environments. With their corrosion and rust resistance, high-temperature resistance, wear and tear resistance, chemical resistance, and high-strength properties, steel extruders can keep working efficiently in even the toughest conditions. When you need an extruder that can handle almost anything you can throw at it - pick steel for unsurpassed toughness and durability.