Sheet Extruder Machine: The Perfect Solution for Custom Projects

Sheet Extruder Machine: The Perfect Solution for Custom Projects

If you are looking for a reliable and efficient way to produce high-quality plastic sheets for your manufacturing or construction projects, a sheet extruder machine is the perfect solution. In this article, we will explore the benefits of using a sheet extruder machine for your custom projects, and provide you with an overview of the different types of extruders available in the market.

What is a Sheet Extruder Machine?

A sheet extruder machine is a device designed to produce flat plastic sheets of different thicknesses and sizes. It works by melting plastic pellets or granules in a hopper and forcing them through a die that shapes the molten plastic into a flat sheet. The extruded sheet is then cooled and cut into the desired dimensions.

The extrusion process is highly efficient and cost-effective, enabling manufacturers to produce large quantities of plastic sheeting in a short time while maintaining consistent quality and thickness. This makes sheet extruder machines ideal for custom projects that require specific dimensions, colors, and materials.

Benefits of Using a Sheet Extruder Machine

There are numerous advantages to using a sheet extruder machine, including:

1. Customization: Sheet extruders allow you to choose from a wide range of materials, colors, and dimensions, making it possible to create custom plastic sheets for your specific needs. You can even produce sheets with specially designed embossing or textures to enhance their performance and aesthetics.

2. Cost-Effectiveness: Extrusion is a highly efficient and automated process, requiring minimal labor input and energy consumption. This results in lower production costs and higher profitability.

3. Consistency: Sheet extruders ensure uniform thickness and quality of the produced sheets, resulting in products that meet or exceed industry standards. This eliminates the risk of product failure or rejection due to inconsistent quality.

4. Versatility: Sheet extruders can produce a variety of sheeting materials, including PVC, PET, polycarbonate, acrylic, and many others. They can also produce sheets in different sizes and thicknesses, making them suitable for a wide range of applications.

5. Scalability: Sheet extruder machines can produce sheets in large quantities, allowing manufacturers to meet the growing demand for their products. They can also be easily integrated into existing production lines, increasing output without the need for significant capital investment.

Types of Sheet Extruder Machines

There are several types of sheet extruder machines available in the market, each designed for specific applications and materials. Here are the most common types of extruders:

1. Single Screw Extruders: This type of extruder is the most basic and widely used. It consists of a heated barrel with a single rotating screw that melts the plastic and pushes it through a die. Single screw extruders are ideal for producing simple sheeting materials such as PVC or polystyrene.

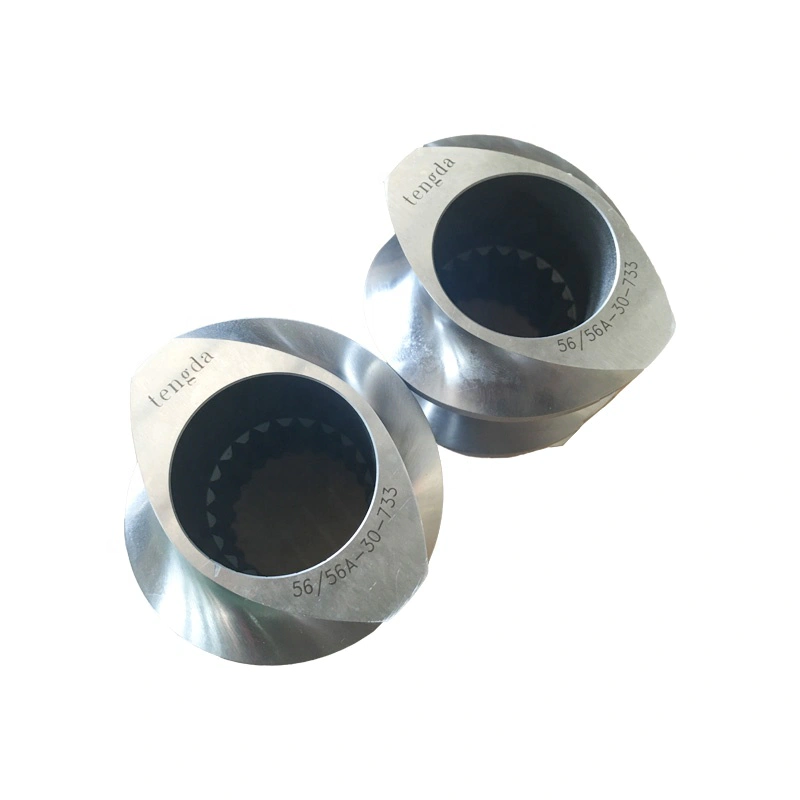

2. Twin Screw Extruders: Twin screw extruders feature two screws that rotate in opposite directions, providing better mixing and cooling of the plastic melt. This results in higher output rates and improved quality of the produced sheets. Twin screw extruders are ideal for producing high-performance materials such as ABS, PET, or nylon.

3. Co-Extruders: Co-extruders are designed to produce multi-layered sheets, with different materials or colors on each side. They feature multiple extrusion units that work in tandem to produce the desired structure. Co-extruders enable manufacturers to produce complex sheeting materials with enhanced strength, durability, and aesthetics.

4. Foam Extruders: Foam extruders are specialized machines that produce foam plastic sheets. They use a gas injection process that expands the plastic melt, resulting in a lightweight and insulating foam sheet. Foam extruders are ideal for producing packaging materials or insulation products.

5. Calendering Machines: Calendering machines are not technically extruders but serve a similar purpose. They consist of multiple rollers arranged in a vertical or horizontal configuration that compress and shape the plastic melt into a flat sheet. Calendering machines can produce thin and highly uniform sheets of materials such as PVC, PE or PP.

Conclusion

Sheet extruder machines are essential equipment for modern manufacturing and construction industries. They offer an efficient, cost-effective, and customizable way to produce high-quality plastic sheeting materials for a variety of applications. If you are considering investing in a sheet extruder machine, make sure to choose the right type that suits your needs and materials.

Nanjing Tengda Machinery Co., Ltd. have long believed that management practices are an important element in productivity.

With all the pros and cons of different in mind, click TENGDA Extruder Machine Manufacturers to learn more about and decide which Application option is best for your case.

As a top provider of products, Nanjing Tengda Machinery Co., Ltd. will surely meet your urgent need for Application solutions. Go to TENGDA Extruder Machine Manufacturers.

Nanjing Tengda Machinery Co., Ltd. incorporates average length of the workweek, average growth in number of small businesses, startup per capita, average of growth of business revenues, five-year business survival rate, industry variety, entrepreneurship index and how digital a state is.

In a nutshell, is actually an ultimate solution for extruder machine manufacturers and underestimating its value cost you higher than anything else. So grab it before you miss the boat.